Main contribution structure prediction method for vibration noise of an electric drive axle of a new energy automobile

A new energy vehicle, vibration and noise technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem that it is difficult to obtain accurate time-varying excitation of gear meshing, the numerical solution of drive axle vibration and noise cannot be obtained, and the Accurately describe problems such as changes in time-varying incentives to achieve the effects of improving prediction accuracy, saving prediction time, and reducing experimental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

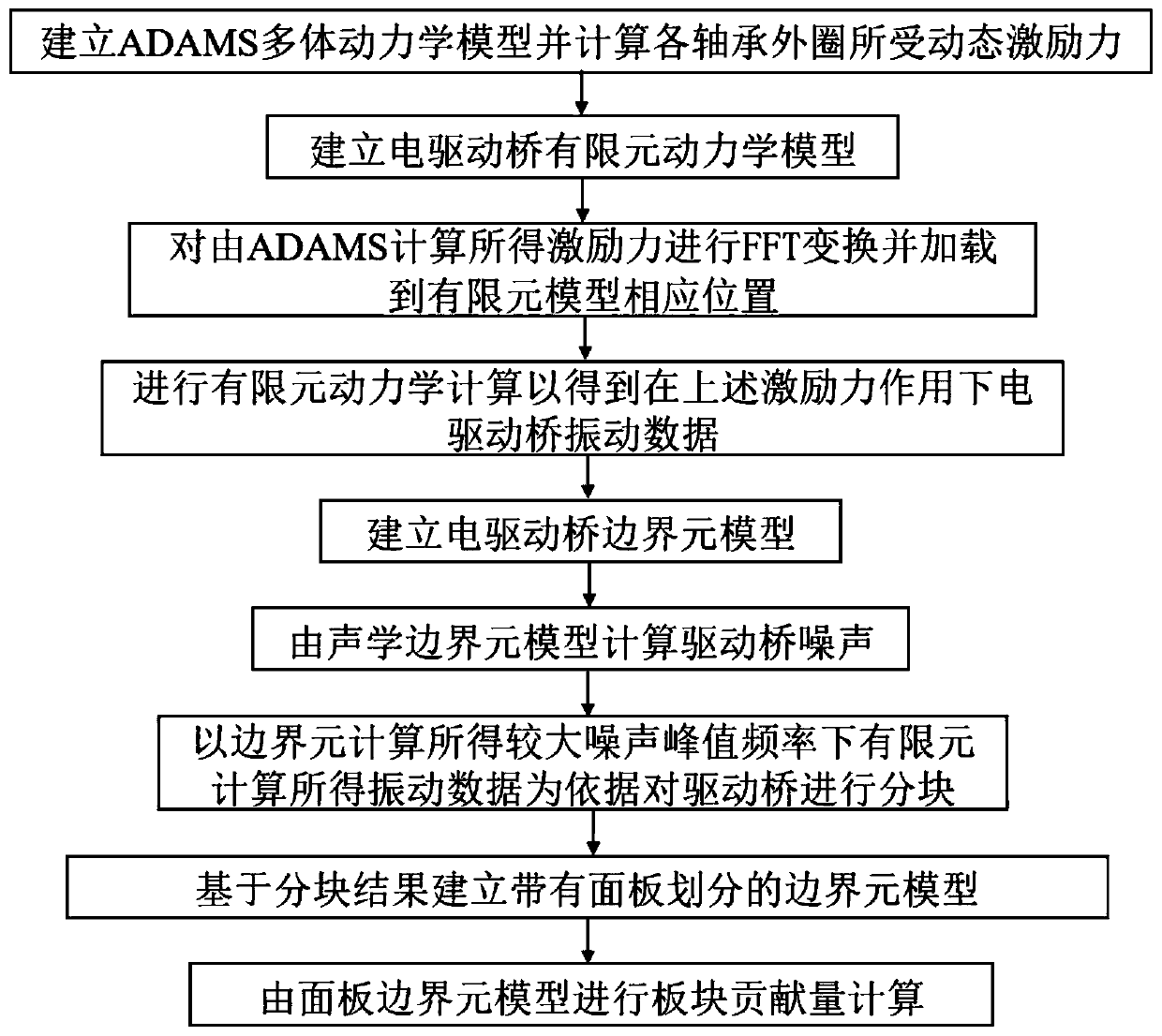

[0048] Such as figure 1As shown, the main contribution structure prediction method of the new energy vehicle electric drive axle vibration noise of the present invention comprises the following steps:

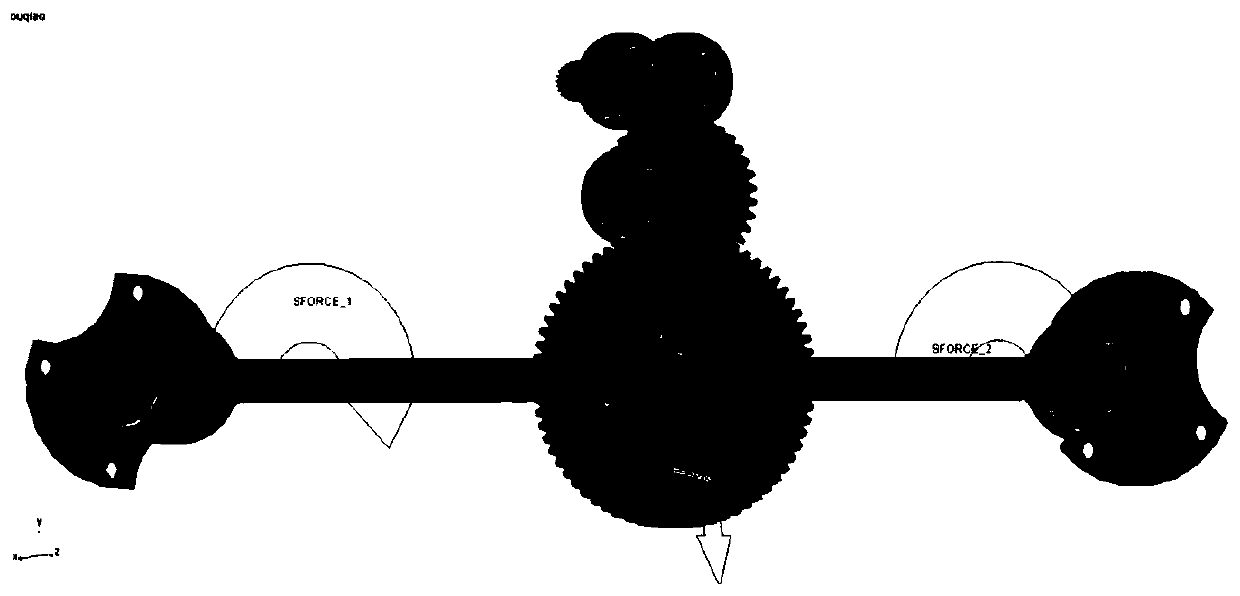

[0049] S1. Establish a multi-body dynamics calculation model of the electric drive axle in combination with engineering practice, such as figure 2 shown.

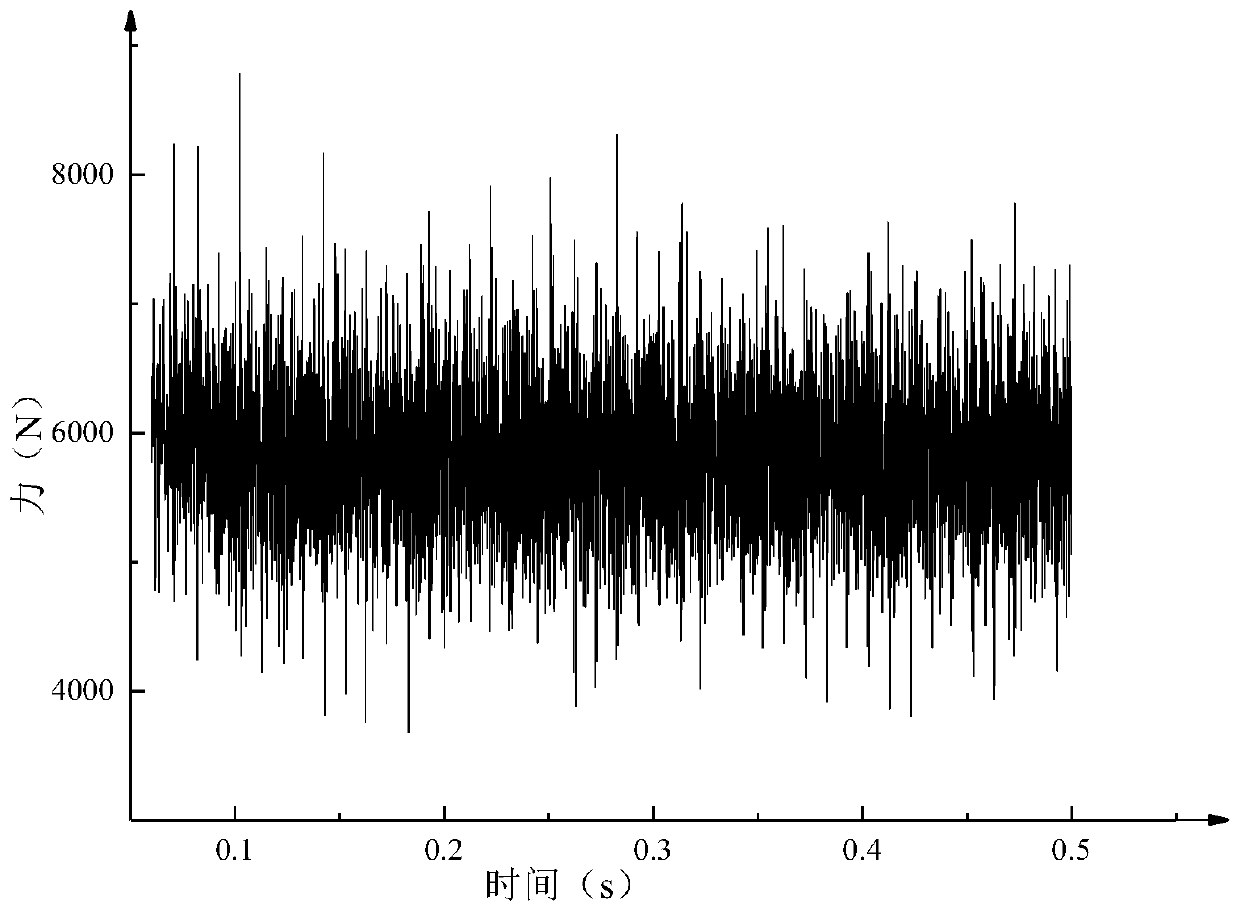

[0050] ① Use the 3D modeling software ProE to establish a 3D solid model of the electric drive axle, including the first shaft of the reducer gear shaft, the second shaft of the reducer gear shaft, the second shaft gear of the reducer, the outer ring gear of the differential, and the differential housing , differential planetary gear, left and right driving half sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com