Pre-buried cable

A cable and pre-embedded technology, which is applied in the direction of cable joints, etc., can solve the problems that affect the normal use of the cable body, the disconnection of the cable body, the easy damage and moisture at the docking position of the cable body, and reduce the factors of normal power supply use and power transmission , reduce easy damage and moisture, improve the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical solution of the present invention clearer, the present invention is further described in detail in conjunction with the following examples. It should be understood that the specific embodiments described here are only used to explain the invention, not to limit the invention.

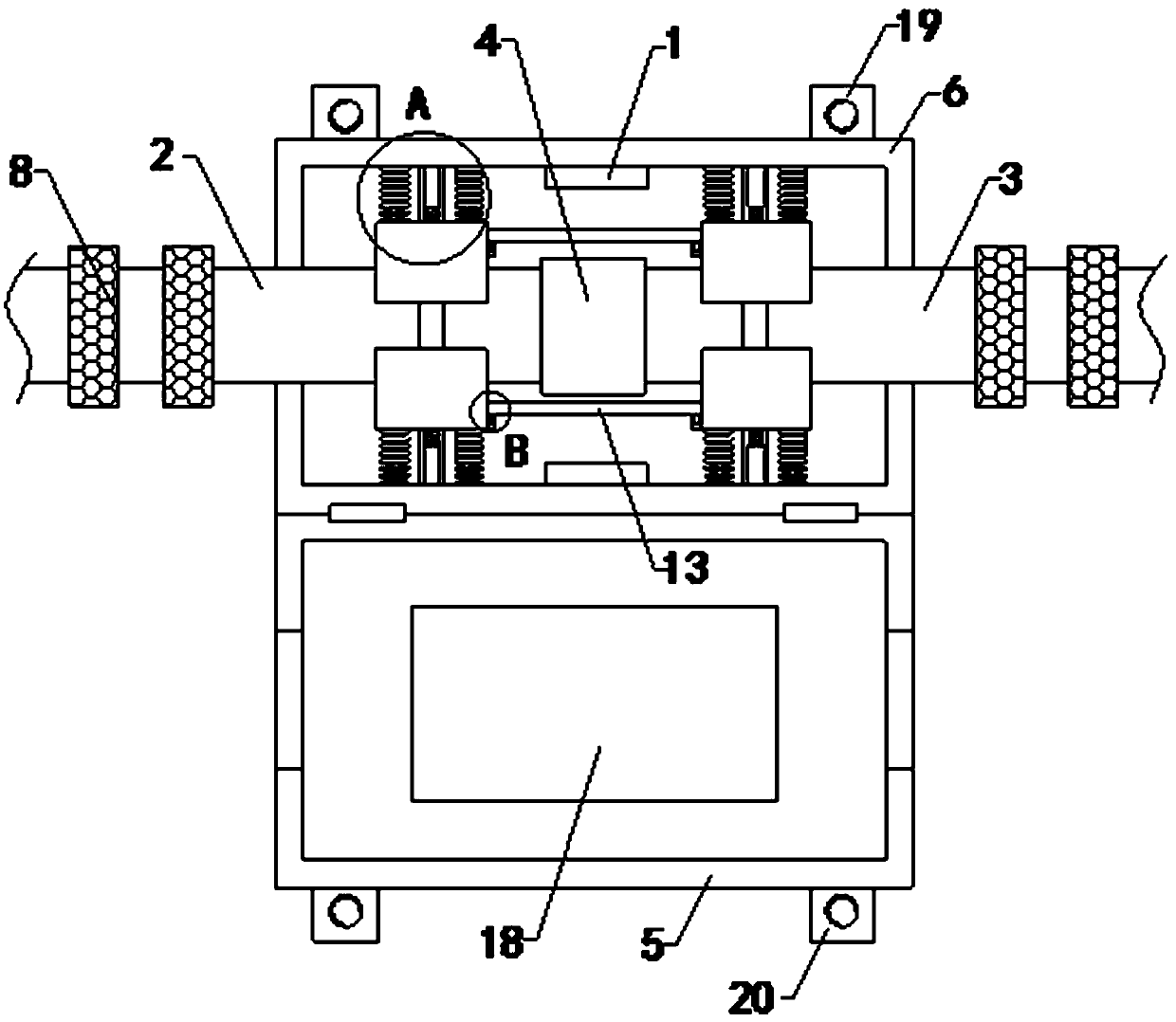

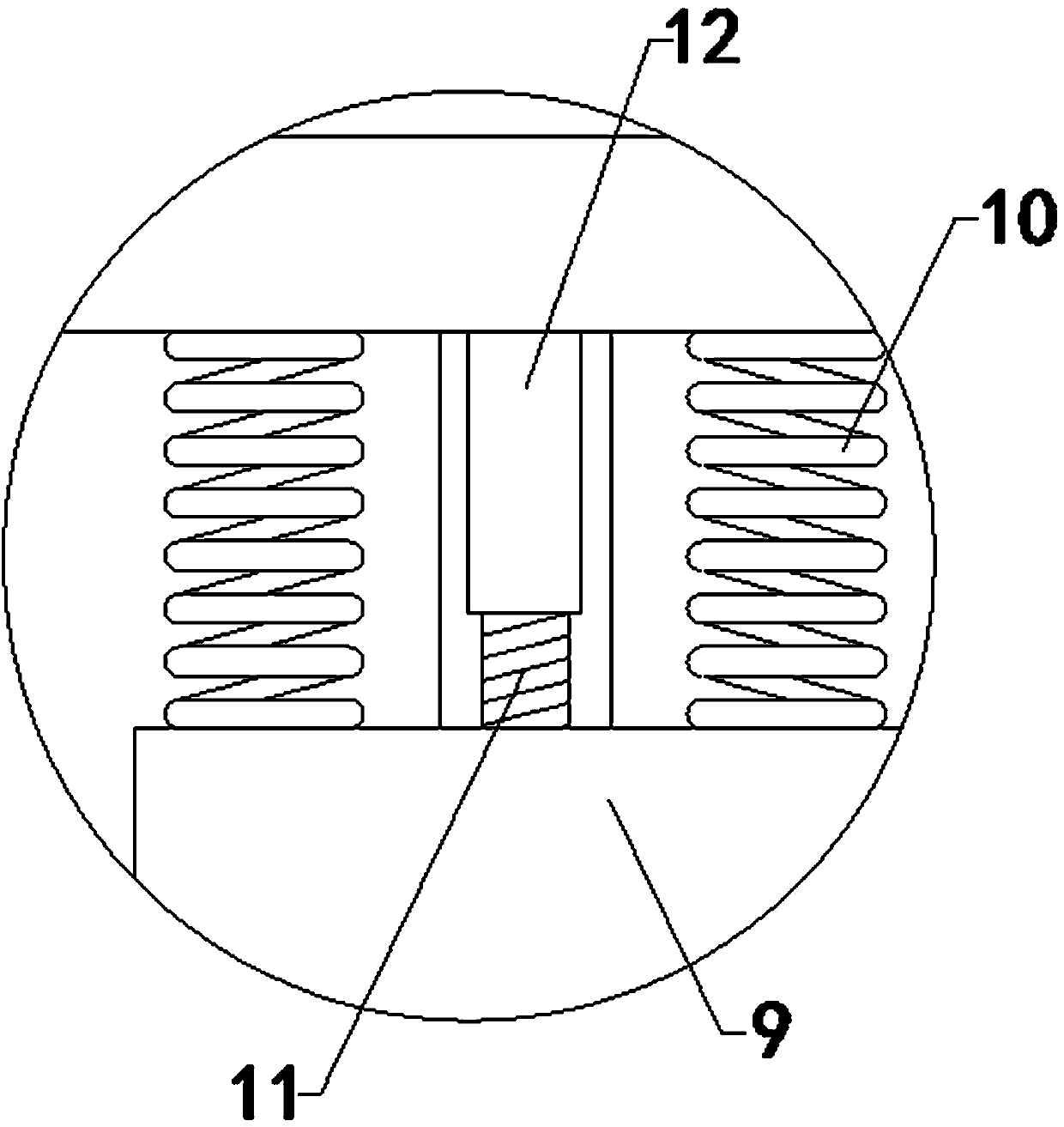

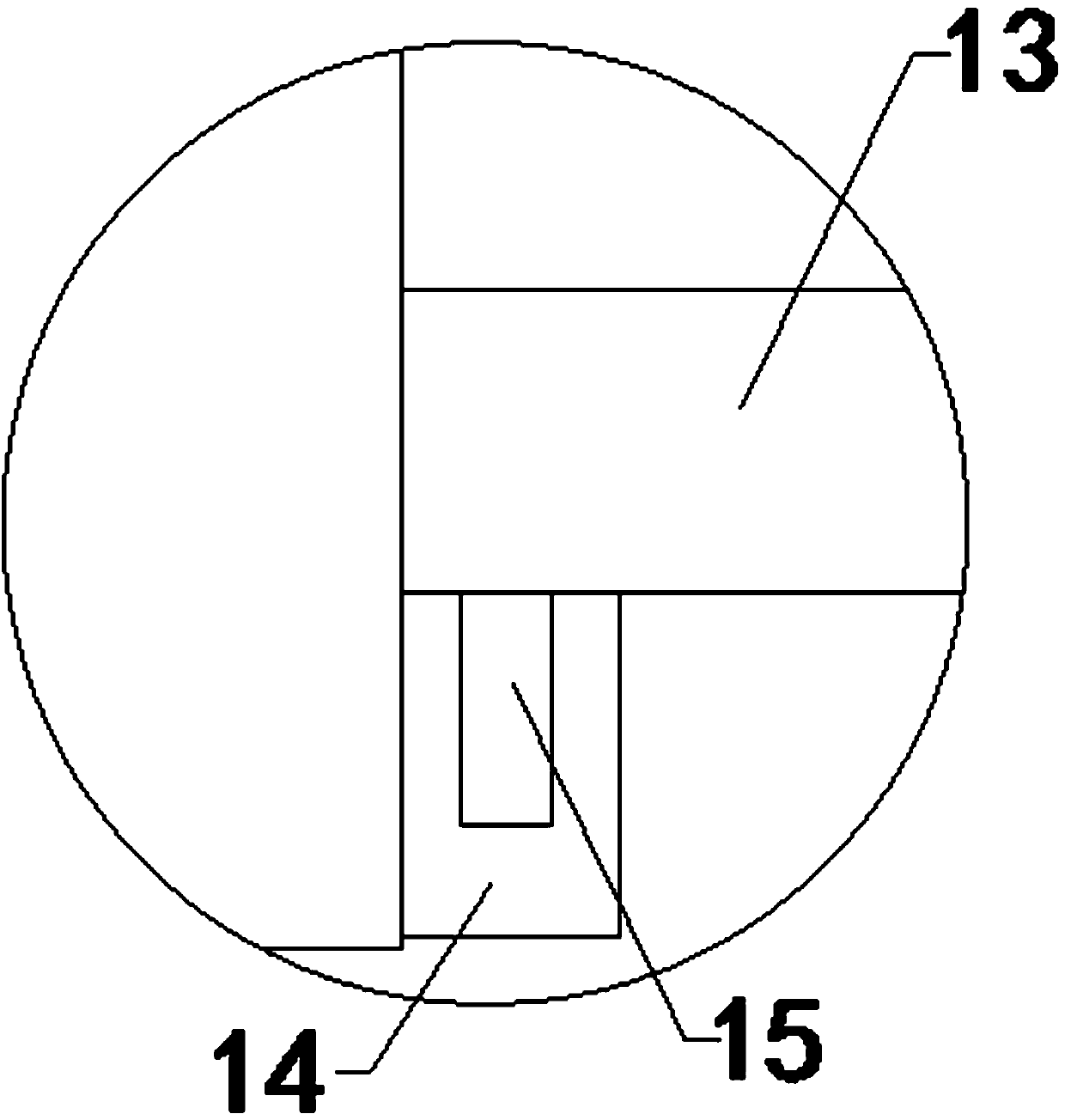

[0018] refer to Figure 1 to Figure 6, a pre-embedded cable of the present invention, including a cable body; including a protective box and two sets of mesh drying boxes 1, the cable body includes a first cable body 2 and a second cable body 3, and the first cable body 2 and the second cable body The docking position of the two cable bodies 3 is set as a connecting part 4, the protective box includes a lower protective cover 5 and an upper protective cover 6, and the top end of the lower protective cover 5 and the bottom end of the upper protective cover 6 are rotatably connected by multiple sets of hinges, The left side wall of lower protective cover 5 and the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com