A device for separating cutting fluid from iron filings

A separation device and chip fluid technology, applied in the field of mechanical processing, can solve the problems of incomplete separation of iron filings and chip fluid, low efficiency of chip fluid recovery, etc., and achieve the effect of ingenious structure, high efficiency, thorough and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

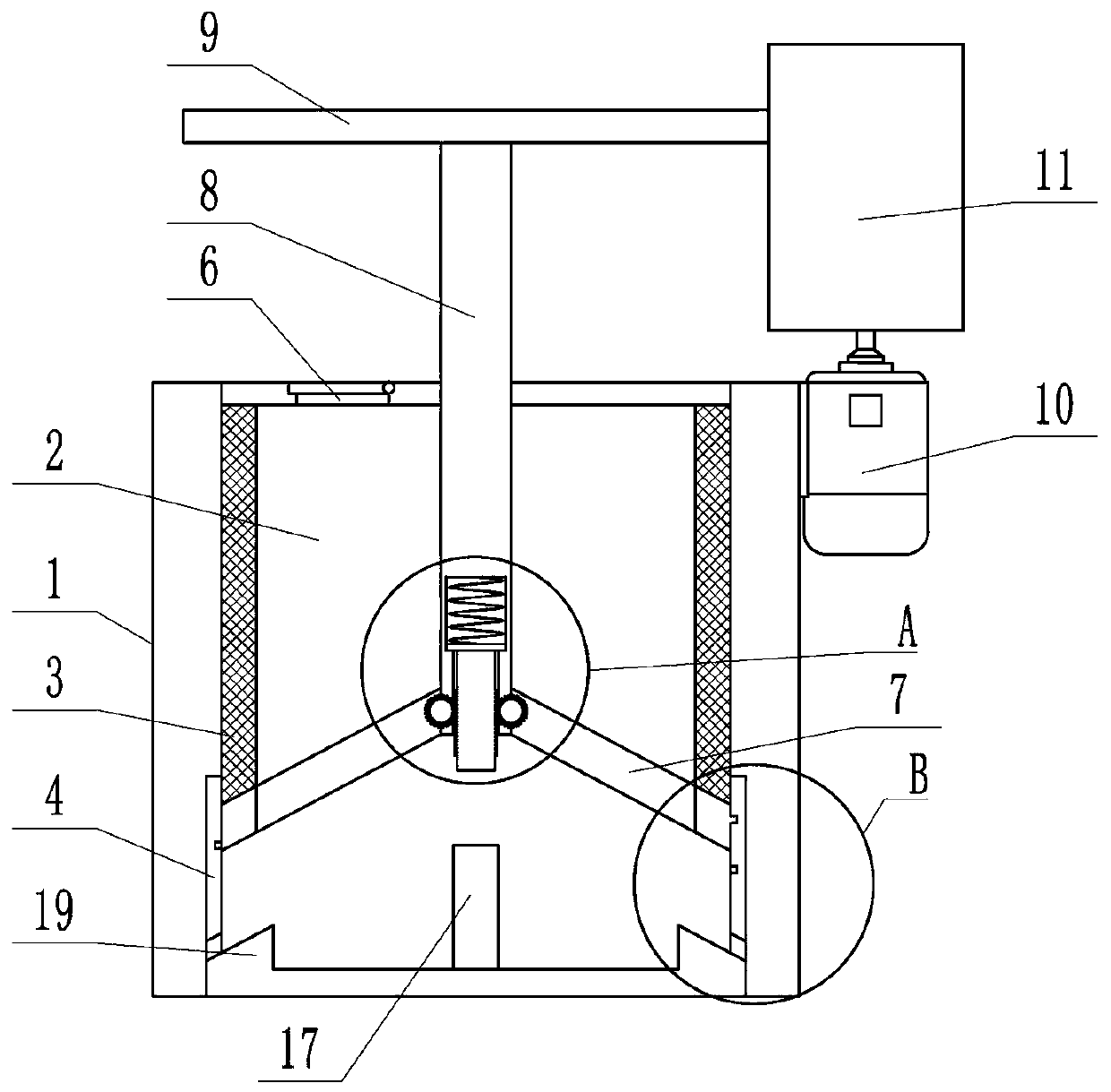

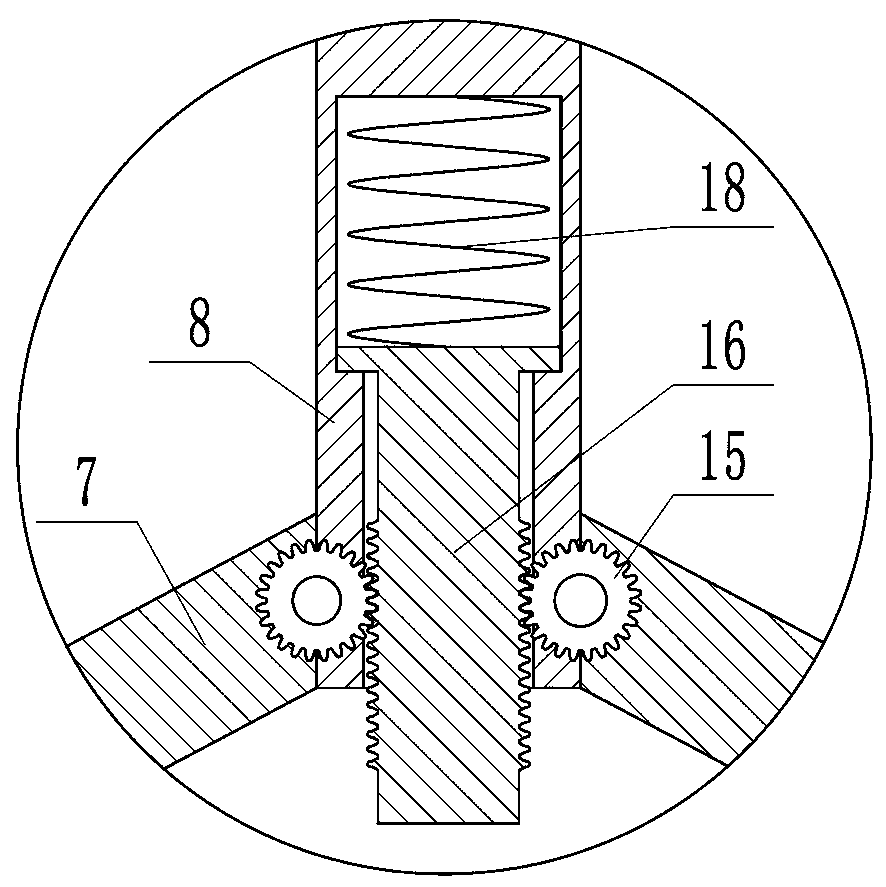

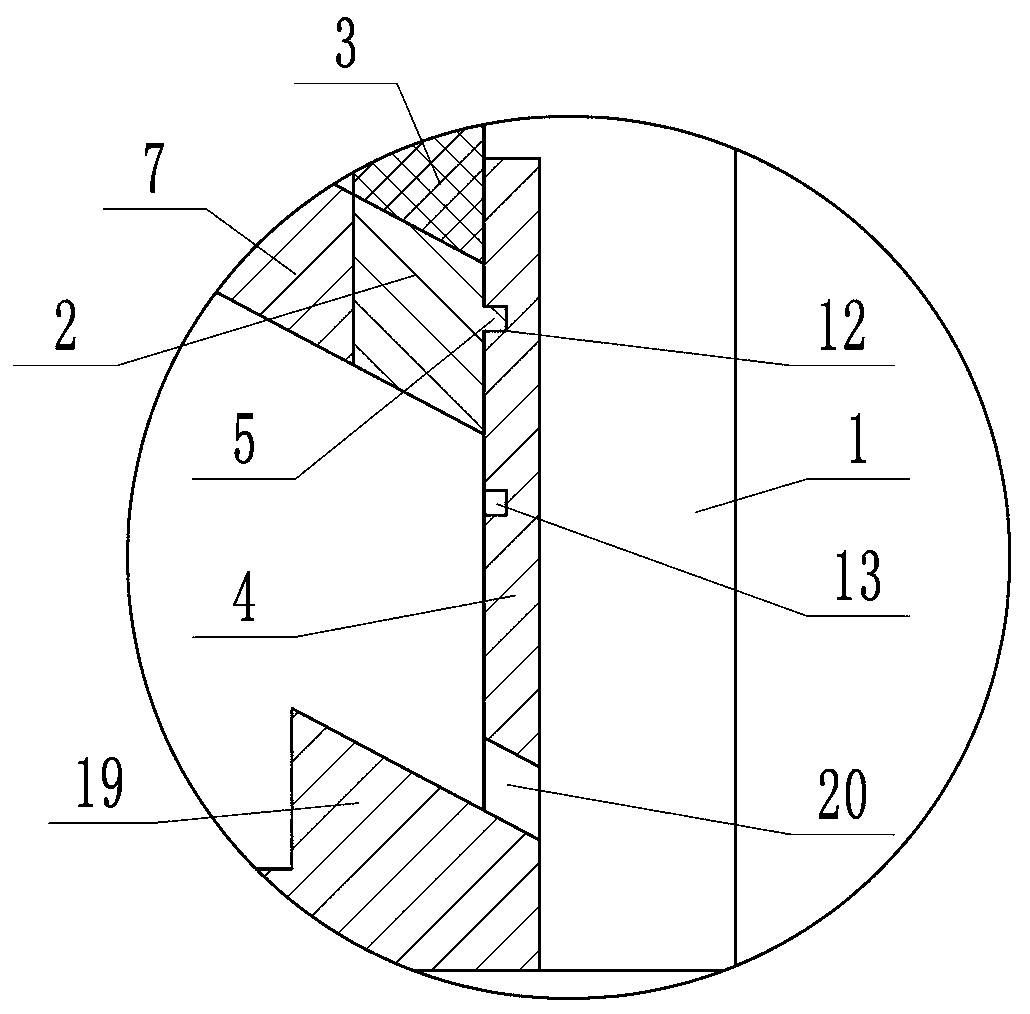

[0014] The following is attached Figure 1 to Figure 7 The specific implementation manner of the present invention will be described in further detail.

[0015] Depend on Figure 1 to Figure 7 It can be known that a separation device for cutting liquid in iron filings includes a liquid collecting bucket 1 and a dumping bucket 2, the spinning bucket 2 is movable and fixed inside the liquid collecting bucket 1, the outer wall of the spinning bucket 2 is a filter screen 3, and the inner bottom of the liquid collecting bucket 1 There is a fixed plate 4 positioned at the outer side of the bucket 2, the fixed plate 4 is provided with a spiral groove, and the positioning rod 5 inserted into the spiral groove protrudes from the bucket 2, and the positioning rod 5 slides in the spiral groove to make the bucket 2 in the spiral groove. The liquid collecting barrel 1 rotates and vibrates up and down. The upper part of the throwing barrel 2 is provided with a feed port 6, and the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com