Preparation method of high-flux biological pollution resistant reverse osmosis membrane

An anti-biological fouling, reverse osmosis membrane technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc. Increase the anti-biofouling ability and application durability, save costs, and enhance the effect of anti-adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

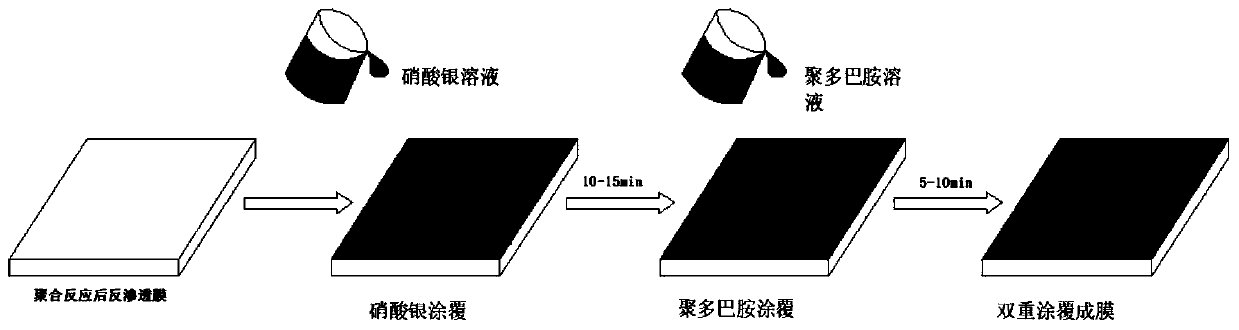

Method used

Image

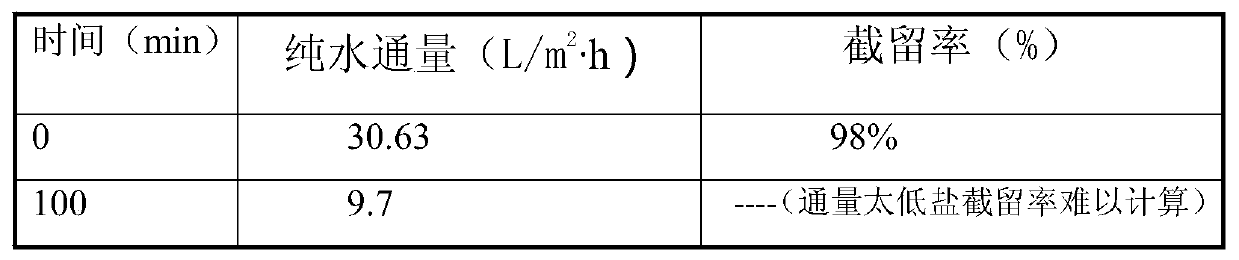

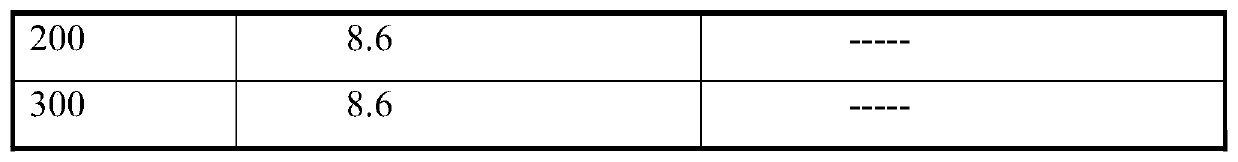

Examples

Embodiment 1

[0018] Preparation of aqueous phase solution: preparation of 1L aqueous solution of 2wt% m-phenylenediamine;

[0019] Prepare organic phase solution: prepare 1L of n-hexane solution of 0.2wt% trimesoyl chloride;

[0020] Preparation of silver nitrate solution: prepare 0.5L of silver nitrate solution with a concentration of 1mmol / L;

[0021] Preparation of dopamine solution: Dissolve dopamine in Tris-HCl buffer solution with a pH of 8.5 to prepare 0.5 L of dopamine solution with a concentration of 1 mmol / L, and then magnetically stir the dopamine solution at room temperature for 5 hours;

[0022] Weigh 150mg of carbon nanotubes, first add 150ml of a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1, ultrasonically oscillate for 1 hour, dilute the obtained solution with deionized water, filter it with a microporous membrane, and then use a large amount of deionized water The solid on the membrane was washed until the pH of the ...

Embodiment 2

[0026] Preparation of aqueous phase solution: prepare 0.5L of an aqueous solution of 3.5wt% m-phenylenediamine;

[0027] Preparation of organic phase solution: prepare 1L of n-hexane solution of 0.1wt% trimesoyl chloride;

[0028] Prepare silver nitrate solution: prepare 0.5L of silver nitrate solution with a concentration of 5mmol / L;

[0029] Prepare dopamine solution: dissolve dopamine in Tris-HCl buffer solution with a pH of 8.5, prepare 0.5 L of dopamine solution with a concentration of 5 mmol / L, and stir magnetically at room temperature for 5 h;

[0030] Weigh 180 mg of carbon nanotubes, first add 50 ml of a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1, and ultrasonically oscillate for 1 hour. The solid on the membrane was washed until the pH of the filtrate was 7, and the obtained black precipitate was vacuum-dried at 80° C. to obtain 160 mg of ultrasonically dispersed and acidified carbon nanotubes.

[0031] 150 ...

Embodiment 3

[0034] Preparation of aqueous phase solution: prepare 0.8L of an aqueous solution of 2.0wt% m-phenylenediamine;

[0035] Preparation of organic phase solution: prepare 1L of n-hexane solution of 0.15wt% trimesoyl chloride;

[0036] Preparation of silver nitrate solution: use 0.5L of silver nitrate solution with a concentration of 3mmol / L;

[0037] Preparation of dopamine solution: Dissolve dopamine in Tris-HCl buffer solution with a pH of 8.5, prepare 0.5 L of dopamine solution with a concentration of 2.5 mmol / L, and stir magnetically at room temperature for 5 hours;

[0038] Weigh 160 mg of multi-walled carbon nanotubes, first add 60 ml of a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1, ultrasonically oscillate for 1 hour, dilute the obtained solution with deionized water, filter with a microporous membrane, and then use a large amount of The solid on the membrane was washed with ion water until the pH of the filtrate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap