Plastic wire-arranging steel nail wire clip manual nailing gun

A technology for nailing guns and rowing steel, which is applied in the field of manual nailing guns, and can solve problems such as potential safety hazards and injuries to users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

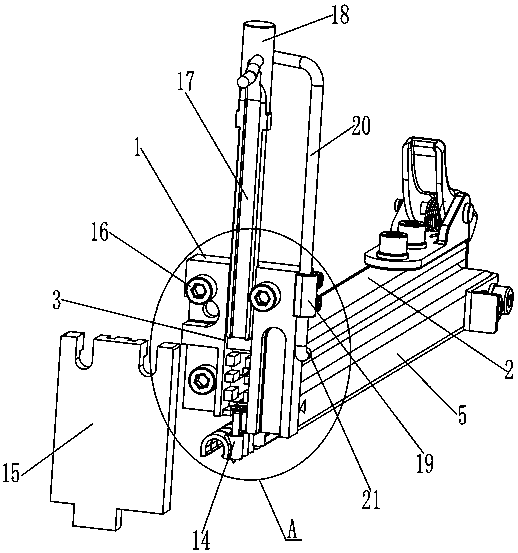

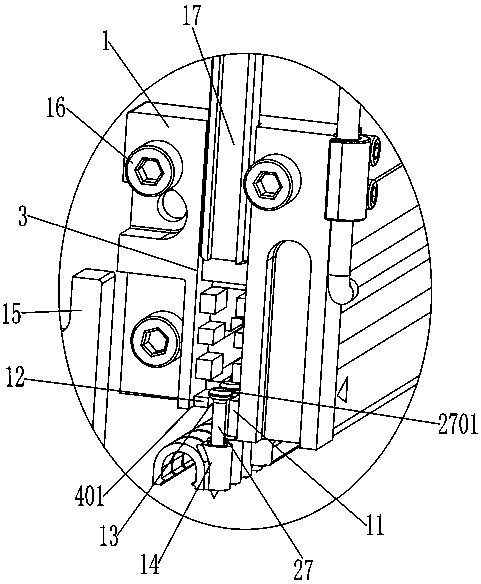

[0024] Example 1, please refer to Figure 1 to Figure 7 as well as Figure 10 , the present invention provides a manual nailing gun with a plastic row of steel nails and wire clips, comprising a gun head 1 and a fixed clip 2 connected to the gun head 1, the upper surface of the gun head 1 is provided with a nailing hole 3 penetrating through itself, The fixed magazine 2 is provided with a nailing groove 4 connected with the nailing hole 3, and the nailing groove 4 is provided with a movable magazine 5 matching the fixed magazine 2, and a spring 6 is installed in the movable magazine 5. 1. The top push rod 7 and the top head 8 are provided with a baffle 9 at the outer end of the movable magazine 5, and one end of the spring 6 is against the baffle 9, and the other end is against the top push rod 7, and the top push rod 7 matches the corresponding top 8 of the bumper 10, the top 8 is in the nailing groove 4 and slides back and forth in the nailing groove 4, and a bar-shaped gap...

Embodiment 2

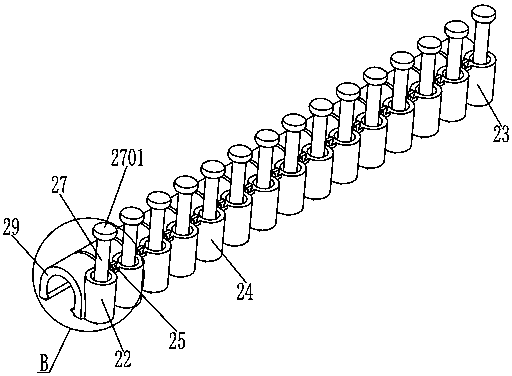

[0029] Example 2, please refer to Figure 8 , Figure 9 , along the direction from the first steel nail seat 22 to the tail steel nail seat 23, the first steel nail seat 22, the middle steel nail seat 24 and the tail steel nail seat 23 are distributed upward in steps.

[0030] The shearing member 25 includes a transverse portion 33 and a longitudinal portion 34 arranged below the transverse portion 33; a shearing head 35 extends outward from the left end of the transverse portion 33; the shearing head 35 is in an inverted triangle shape and cuts The width of the upper end of the head 35 is greater than that of the lower end; the transverse portion 33 , the cutting head 35 and the longitudinal portion 34 are integrally formed.

[0031] Both sides of the inner wall of the lower end of the ferrule 29 are provided with mutually symmetrical limiting strips 36; the cross section of the limiting strips 36 is isosceles triangle.

[0032] Ordinary nailing guns need the handle to be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com