Remote system for PLC equipment debugging and method thereof

A technology of remote systems and equipment, applied in the direction of program control and electrical program control in sequence/logic controllers, can solve problems such as difficulties, and achieve the effect of improving data stability and development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

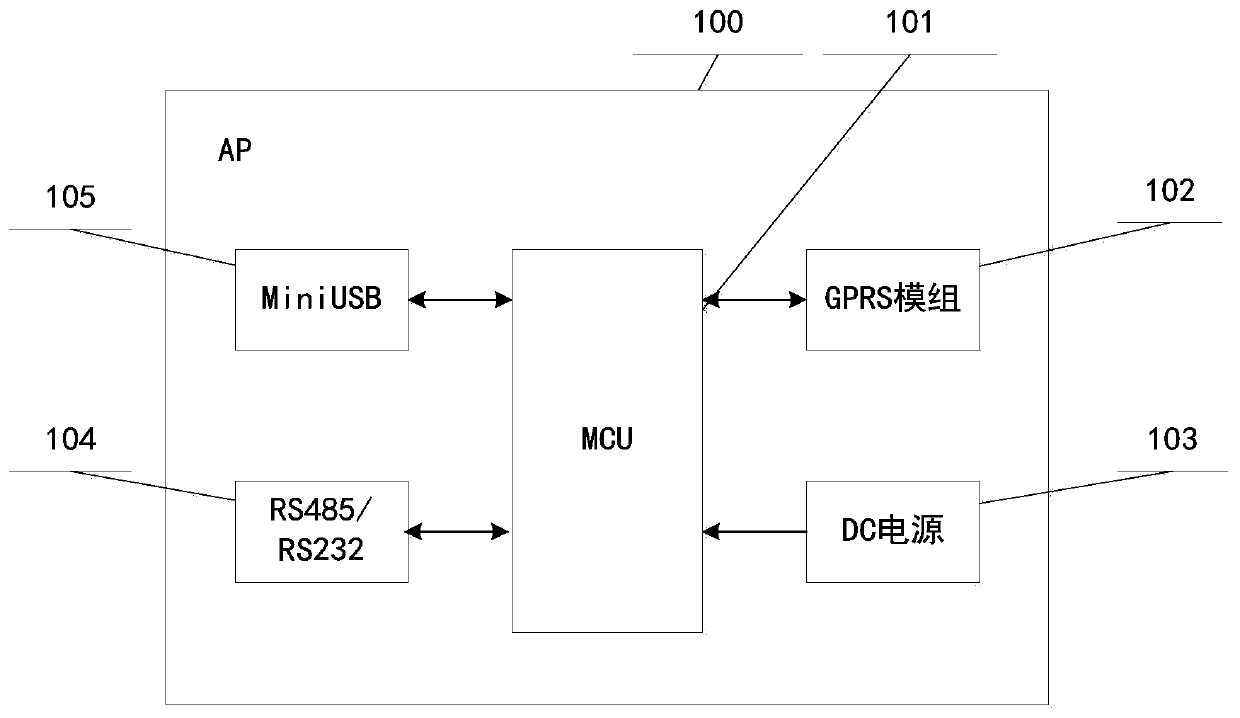

[0021] figure 1 A schematic diagram of the hardware interface of the AP device 100 that facilitates the use of the present invention is shown. The interfaces of the AP include: a micro control unit (MCU) 101 , a GPRS module 102 , a DC power supply interface 103 , an RS485 / RS232 interface 104 , and a MiniUSB interface 105 . Among them, the MCU is the control center of the equipment, the GPRS module is the network data sending and receiving part, the MiniUSB interface is the parameter configuration interface, and the RS485 / RS232 interface is connected to the PLC equipment through wires.

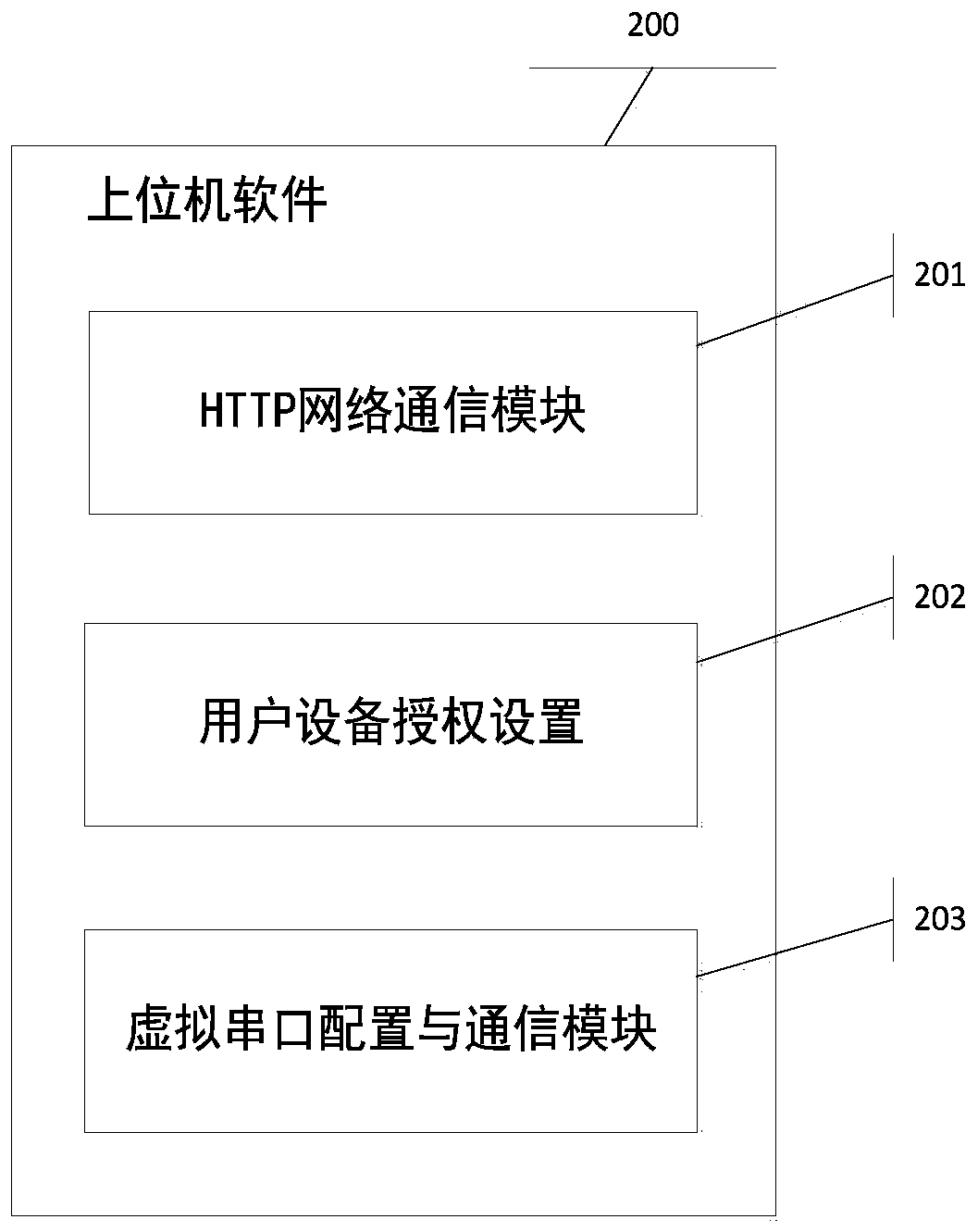

[0022] figure 2 A functional schematic diagram of the host computer software 200 that facilitates the use of the present invention is shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com