First safety control unit, method for operating first safety control unit, second safety control unit, method for operating second control unit, and elevator system

A safety control and elevator system technology, applied to elevators, lifts, transportation and packaging in buildings, etc., can solve problems such as complex safety circuits, achieve easy system maintenance, ensure hardware, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

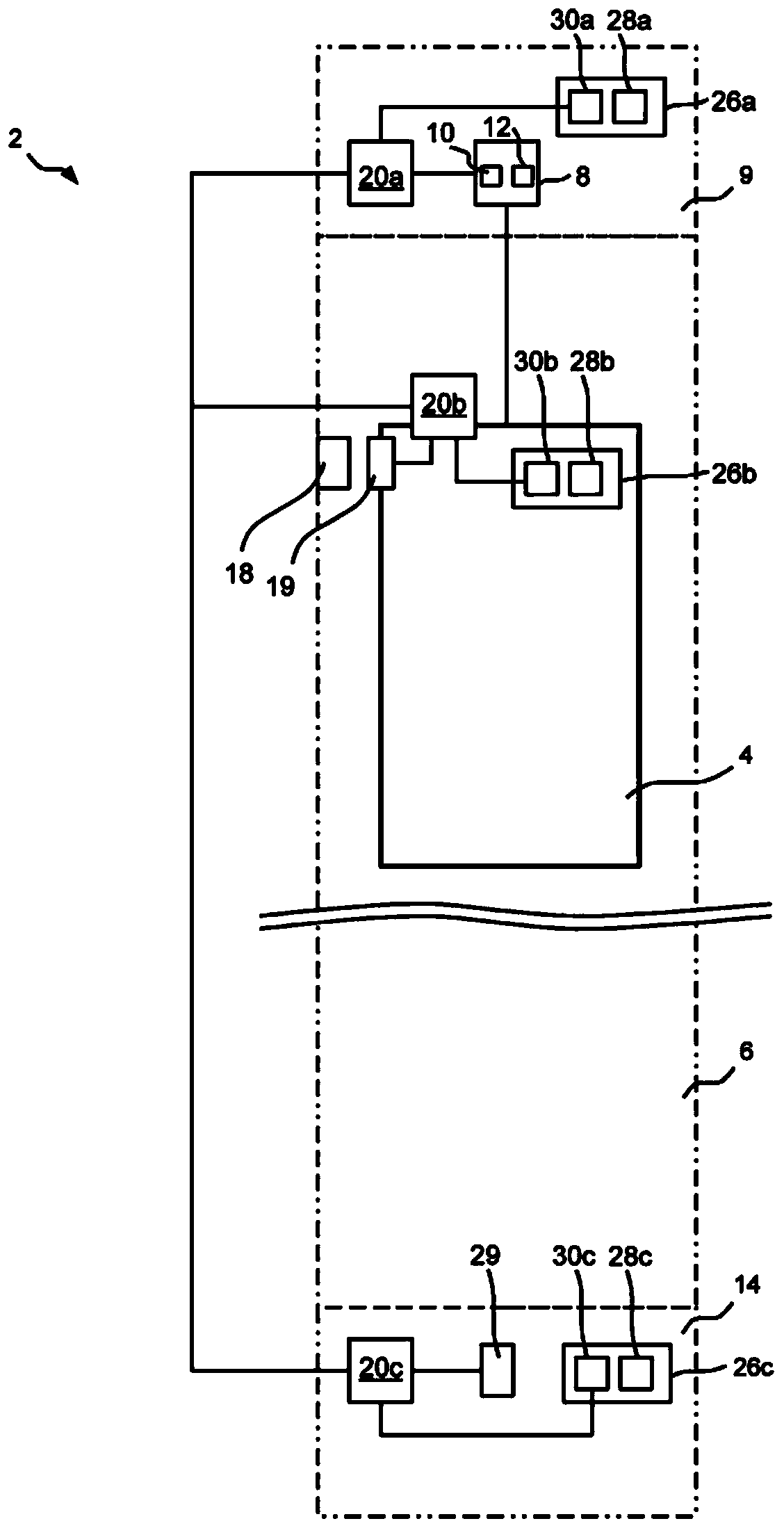

[0027] figure 1 An elevator system 2 is schematically depicted. The cage 4 is arranged in an elevator shaft 6 . The car 4 is operated by a hoist 8 to move up or down. The hoisting machine 8 is arranged in a machine room 9 and includes a mechanical brake 10 and an electric motor 12 . Of course, the elevator system 2 is only shown as an example and can be realized in another way. In another example, lift machine 8 includes a hydraulic motor.

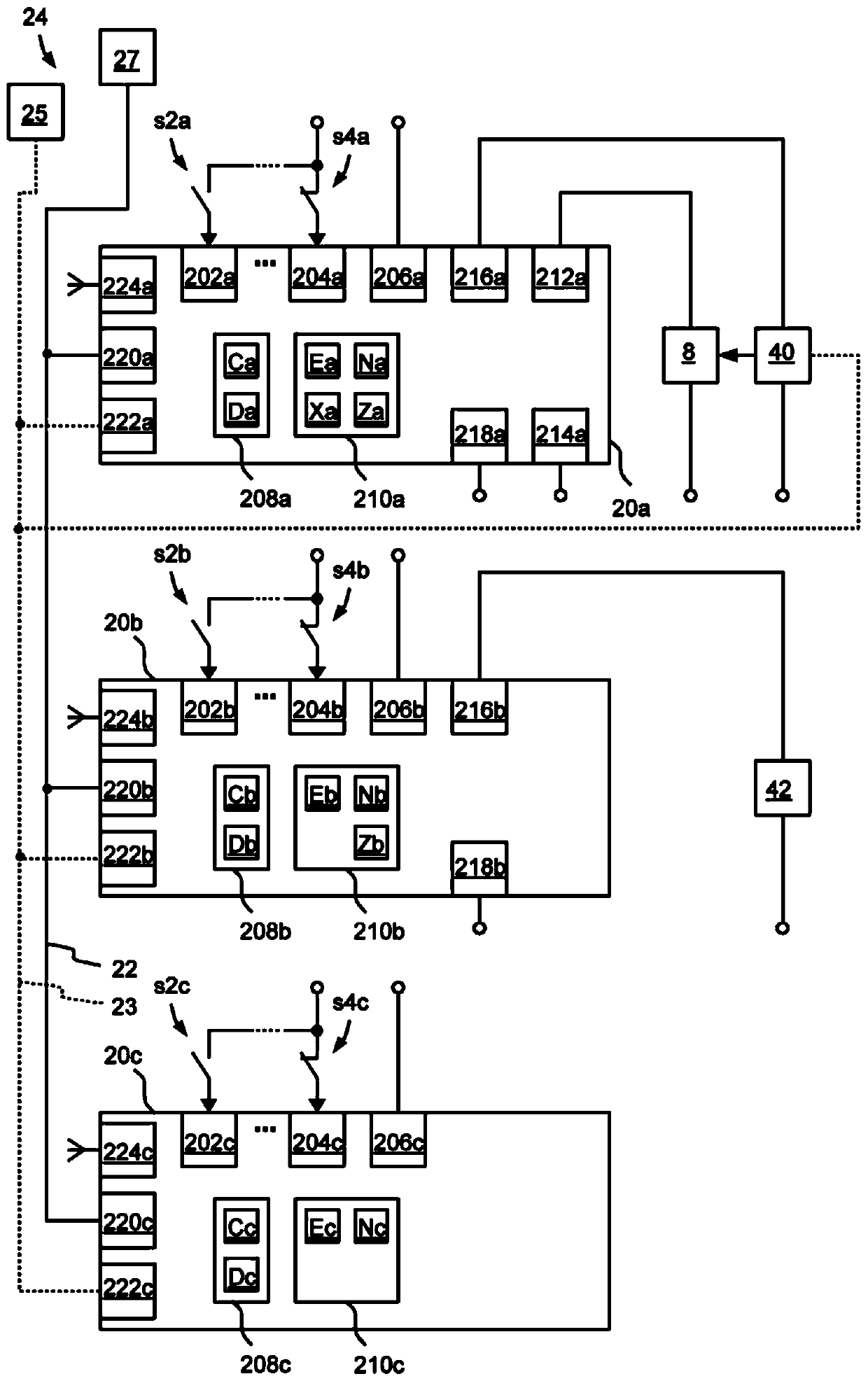

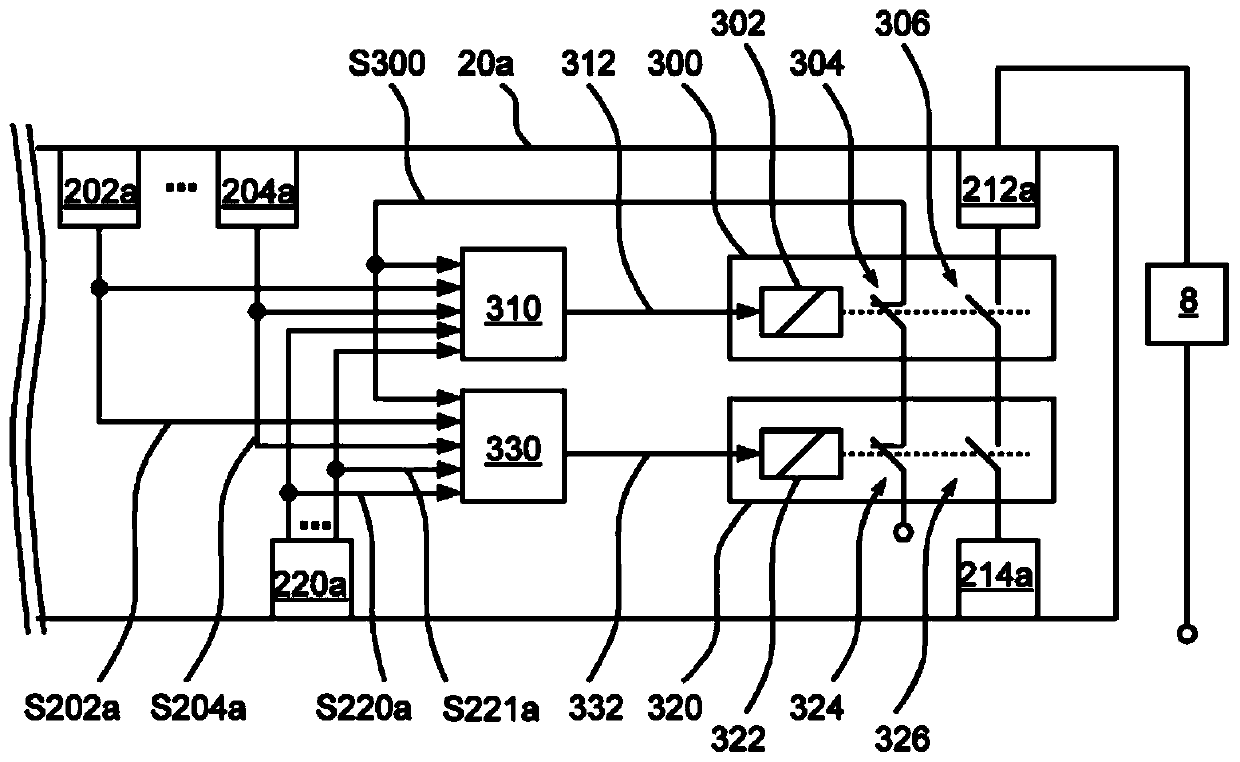

[0028]The first security control unit 20 a is arranged in the machine room 9 . The first safety control unit 20a is used to control the hoisting machine 8 in order to stop the car 4 in case the safety circuit is opened. The second control unit 20b is arranged on the car roof of the car 4 . A further second control unit 20c is arranged at the sump 14 . Most installations of the elevator system 2 will include these three safety control units 20a, 20b and 20c. The safety control units 20a, 20b and 20c are interconnected through a digi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com