A wet purification system suitable for coke oven gas

A technology for wet purification and coke oven gas, which is applied in the fields of combustible gas purification, combustible gas purification/transformation, and removal of gas pollutants. It can avoid secondary pollution, facilitate system maintenance, and achieve high desulfurization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

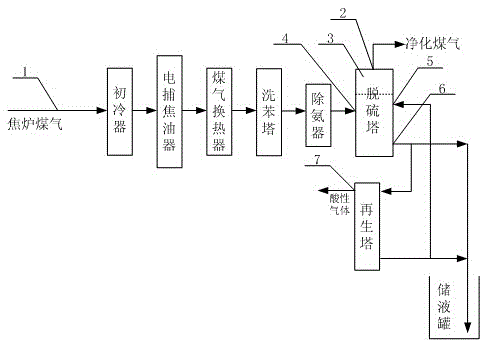

[0026] figure 1 It is the process flow diagram of the wet purification system involved in this embodiment, as figure 1 As shown, the system is mainly composed of primary cooling tower, electric tar catcher, gas heat exchanger, benzene washing tower, ammonia remover and desulfurization tower which are connected with the coke oven gas pipe in sequence. The outlet is sent to the user, and the regeneration tower connected to the desulfurization tower is used to provide desulfurization liquid to the desulfurization tower to remove sulfide and cyanide in the gas.

[0027] In actual industrial production, the coke oven gas is first sent to the primary cooling tower through the coke oven gas pipe 1, then the electric tar catcher removes tar, the gas heat exchanger cools down to 60-80°C, the benzene washing tower removes naphthalene, and the ammonia remover After removing ammonia, the gas is sent to the lower section of the desulfurization tower from the gas inlet 4. Since the desulfu...

Embodiment 2

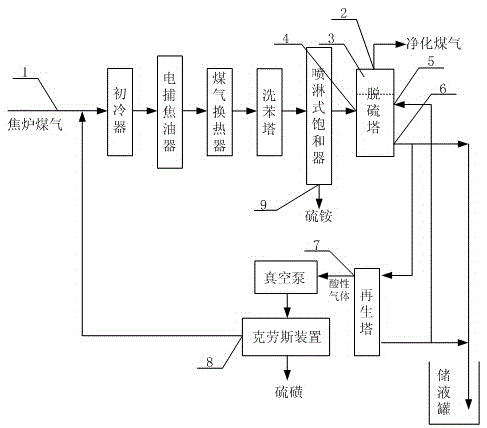

[0030] The difference between this embodiment and embodiment 1 is: as figure 2Shown, the ammonia remover that present embodiment relates to is to be provided with the spray type saturator of ammonium sulfate outlet 9, in actual industrial process, spray type saturator comes from the ammonium sulfate production section, and coal gas is sent into the ammonium sulfate workshop section Spray-type saturator, in the spray-type saturator, it is sprayed with the circulating mother liquor containing 3.5-45% free acid (sulfuric acid), and the circulating mother liquor absorbs the ammonia in the gas to form ammonium sulfate, and the ammonia is removed by the spray-type saturator The ammonia content in the final gas is generally less than 0.05g / m 3 .

[0031] Such as figure 2 As shown, the present embodiment also adds a Claus device on the basis of Embodiment 1, and the regeneration tower regenerates the washing liquid of the desulfurization tower, and the separated acid gas H 2 S, H...

Embodiment 3

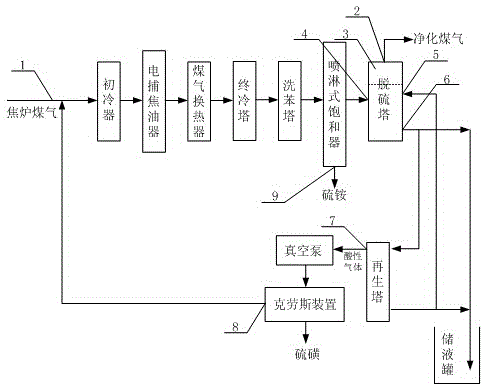

[0033] The difference between this embodiment and embodiment 2 is: as figure 2 As shown, this embodiment adds a final cooling tower on the basis of Embodiment 2. The final cooling tower is arranged between the gas heat exchanger and the benzene washing tower, which can further reduce the temperature of the gas coming out of the gas heat exchanger and prevent high temperature When the coal gas passes through the benzene washing tower to remove naphthalene, it will cause blockage of the equipment, and the temperature of the gas after passing through the final cooler is usually controlled at 30-40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com