Contact lugs for socket-type plug-in connections and socket-type plug-in connections

A technology of plug-in connection and contact piece, which is applied in the parts, contact parts, connection and other directions of the connection device to achieve cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

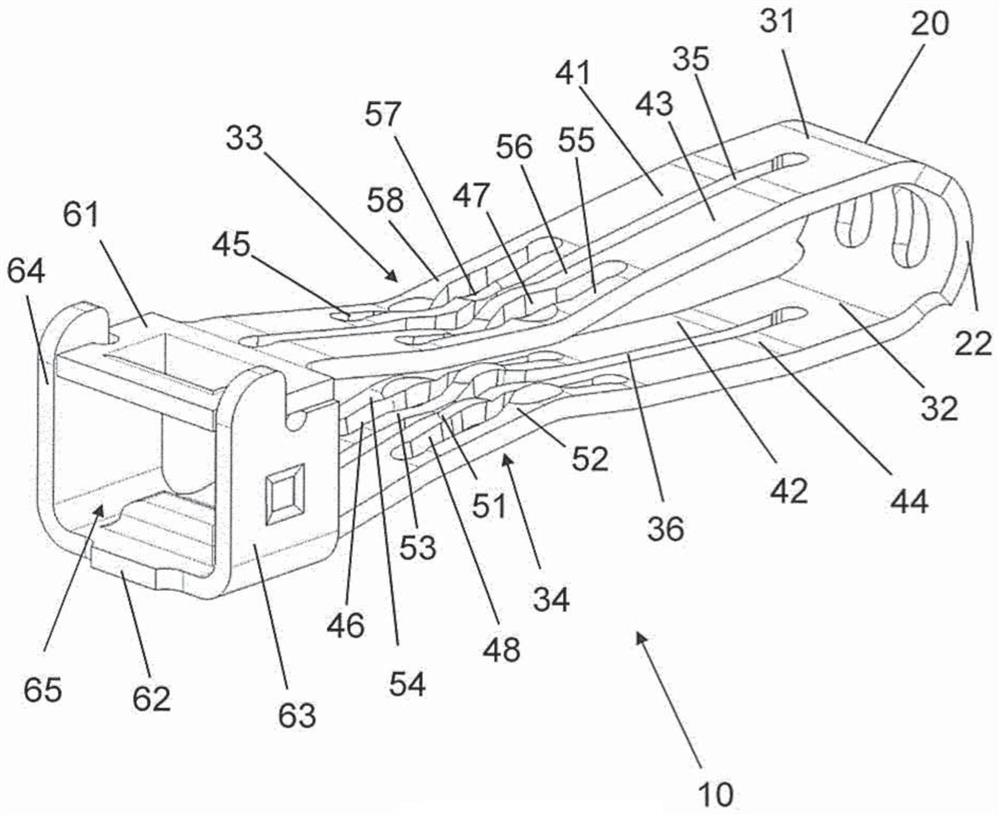

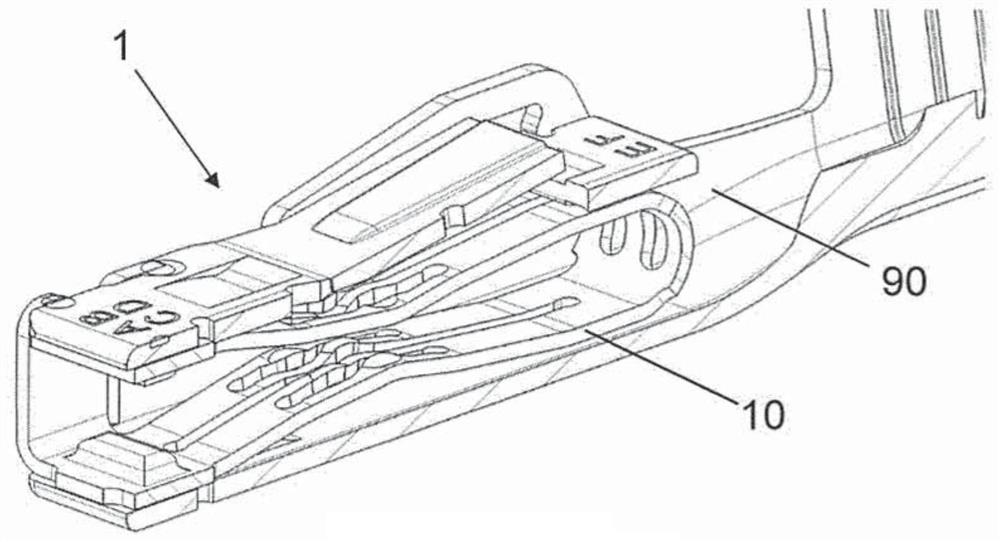

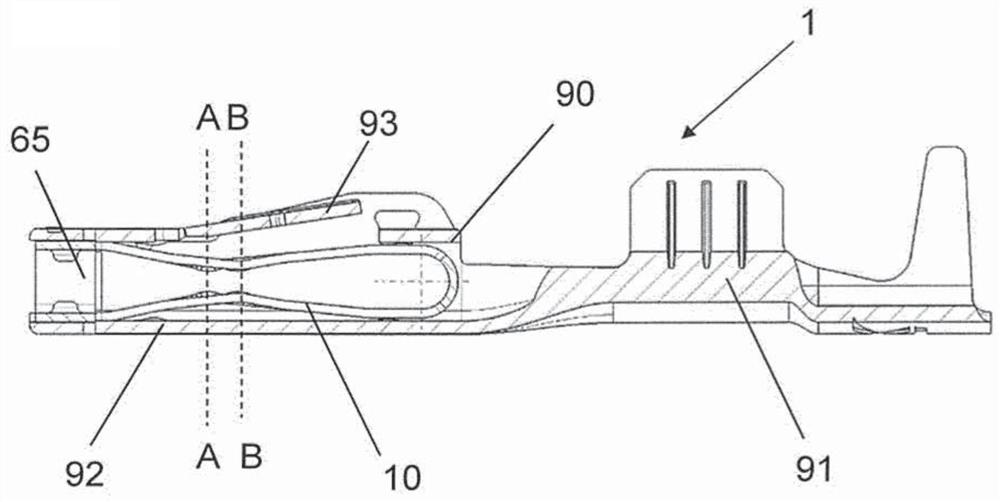

[0017] exist figure 1 A contact lug 10 of a resilient socket-type plug connection part designed according to the invention is shown in FIG. The contact lug 10 is produced in one piece from a strip-shaped sheet 20 as a stamped and bent part.

[0018] The strip-shaped sheet 20 preformed by stamping is bent in a U-shape to form the contact lug 10 , whereby the resulting U-leg forms two mutually opposite contact arms 31 , 32 . Furthermore, the contact arms 31 , 32 are not aligned parallel to each other but have a mutual distance in their longitudinal direction. In each central section 33 , 34 of their longitudinal extension, the mutual spacing of the contact arms 31 , 32 is minimal.

[0019] as in figure 1 It is further shown in , that the middle sections 33 , 34 of the contact arms 31 , 32 do not necessarily coincide with the geometric centers of the contact arms 31 , 32 . More precisely, the figures refer to the position of the sections 33 , 34 connecting the curved portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com