Ultra-large capacitor, high reliability and high temperature resistance measurement and control cable

A super-capacitance, high-temperature-resistant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as the inability to meet the continuous development requirements of military armed helicopter engines and the low capacitance of engine measurement and control cables, and achieve excellent insulation and electrical resistance. The effect of adjustable grounding resistance and improved reliability

Active Publication Date: 2015-10-14

江苏永鼎电气有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The invention patent with the patent application number 201210277573X discloses an aircraft engine measurement and control cable, but the engine measurement and control cable has a low capacitance, which still cannot meet the requirements of the continuous development of military armed helicopter engines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

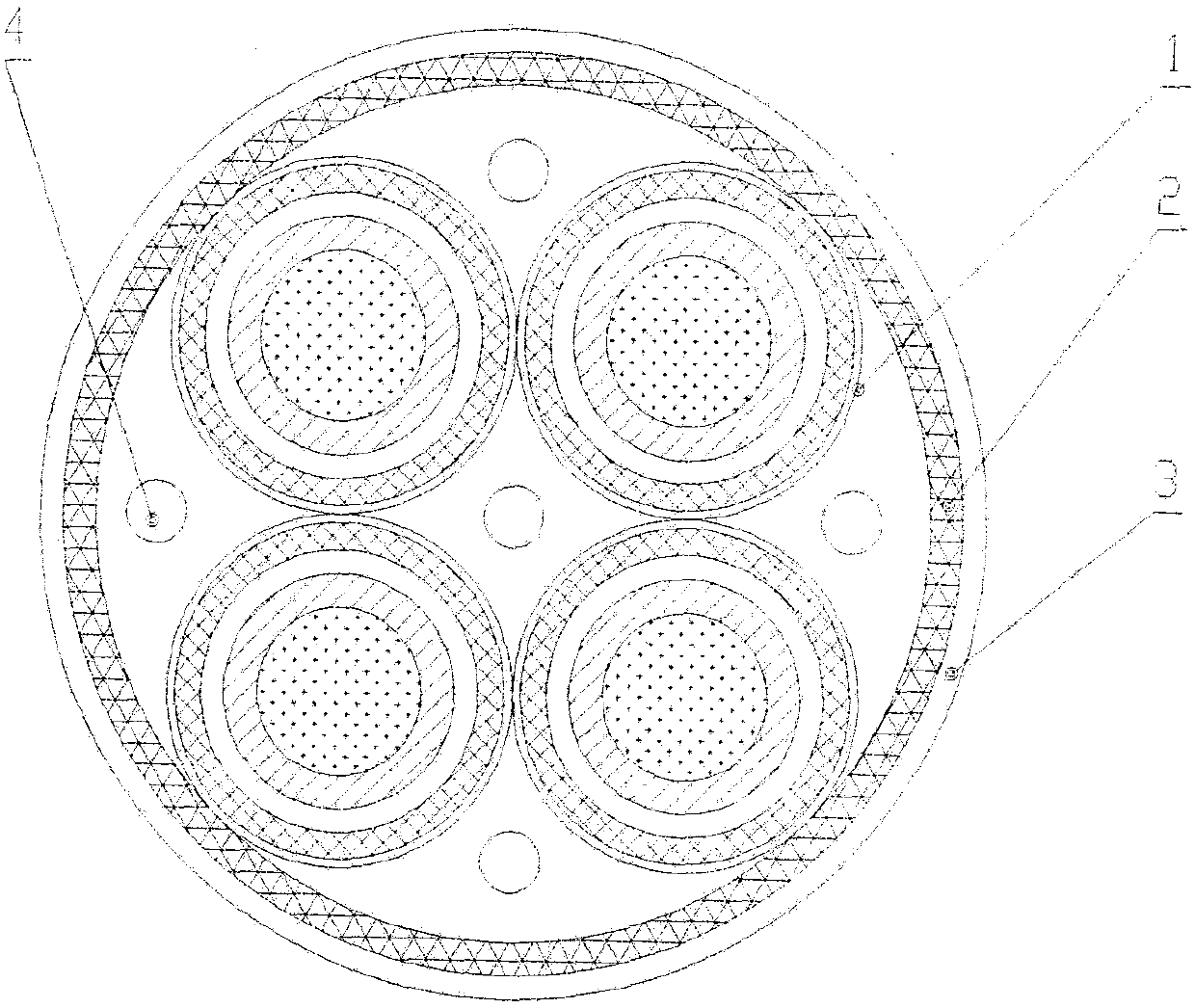

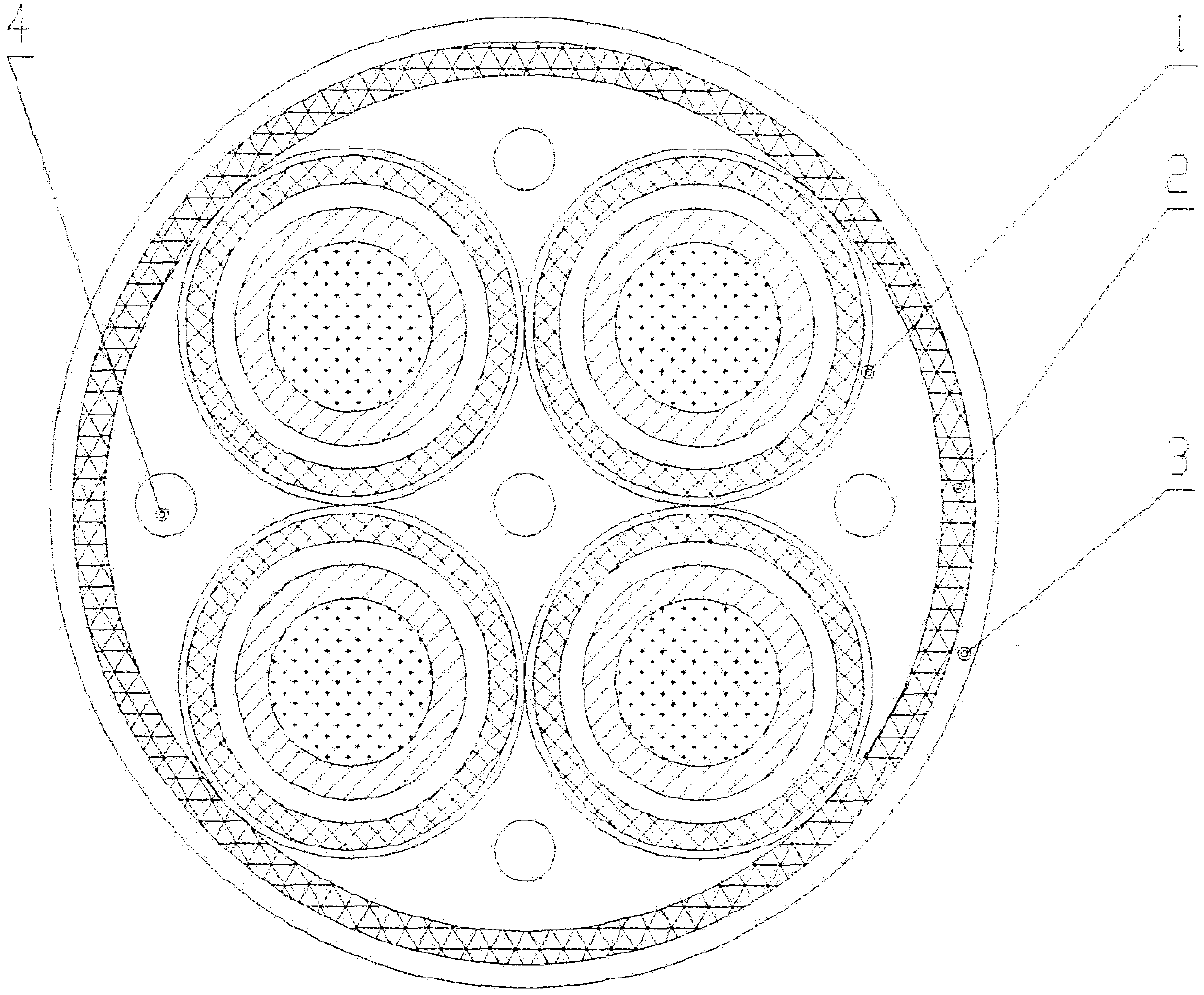

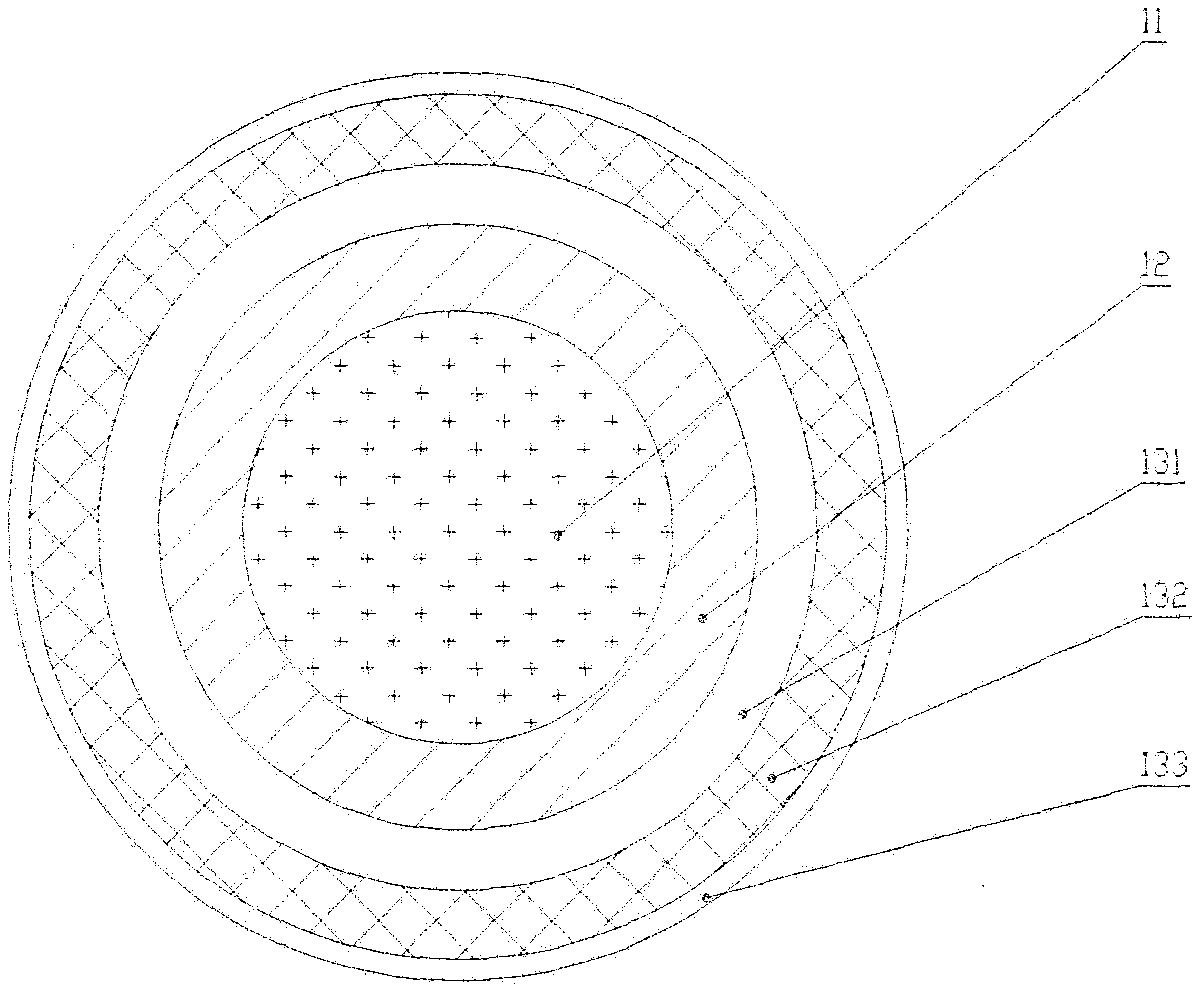

The invention relates to the technical field of cables, in particular to a supercapacitive, high-reliability, high-temperature-resistant measurement and control cable for a new type of armed helicopter engine. It includes several inner cores, the inner core is wrapped in a general shielding layer, the outer side of the general shielding layer is wrapped with a protective layer, the inner core includes silicon carbide fiber bundles, and the outer side of the silicon carbide fiber bundles is wrapped with a metal layer, The metal layer is wrapped with a composite high temperature resistant insulation layer. The composite high temperature resistant insulation layer includes a first synthetic mica layer with a thickness of 0.08-0.10 mm, the outside of the first synthetic mica layer is wrapped with a first silicon carbide fiber layer, and the surface of the first silicon carbide fiber layer is coated with The first high temperature resistant coating. By adopting a specific structure and process, the present invention solves the contradiction that the supercapacitance of the cable, the high temperature resistance, the electric strength and the limit of the total outer diameter of the cable are mutually restricted and cannot be realized simultaneously. The invention can be used for signal transmission between parts of an aircraft engine.

Description

technical field The invention relates to the technical field of cables, in particular to a supercapacitive, high-reliability, high-temperature-resistant measurement and control cable for a new type of armed helicopter engine. Background technique Although my country has made considerable progress in the research and development of military armed helicopters in recent years, the WZ 10 and WZ 19 have all been publicly displayed at air shows, and the army and aviation units have begun to assemble. However, the core component of the aircraft is also known as the heart of the aviation industry - the overall backwardness of the engine has been delaying the development and installation of my country's armed helicopters. The Wuzhi 10 project, which began in the 1990s, suffered twists and turns due to the engine. The engine power used for WZ-10 is still less than 1000kW, which is more than 60% lower than the 1662kW engine of the same kind of helicopter engine in the world (for Apach...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01B7/02H01B7/17

Inventor 钱科朱华山王开宇田广毅钱金子阳常飖强

Owner 江苏永鼎电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com