Thermocouple compensation cable for aircraft engine

An aircraft engine, thermocouple technology, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as reducing the reliability of the engine thermocouple compensation circuit, achieve excellent core-screen capacitance characteristics, improve reliability, and excellent electrical resistance performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

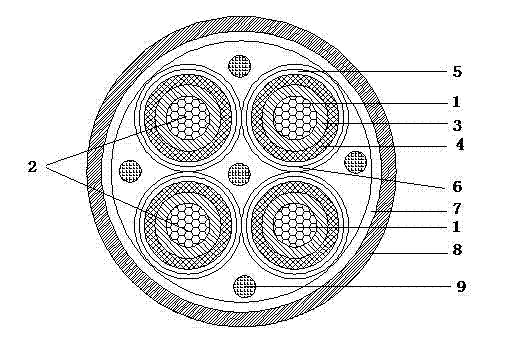

[0024] A thermocouple compensation cable for an aircraft engine, a thermocouple compensation cable for an aircraft engine, which is composed of at least two kinds of wires, each of which is multi-strand, and all the wires are wrapped in the same pure nickel In the wire braided overall shielding layer 7, the pure nickel wire braided overall shielding layer 7 is also wrapped with a FEP sheath 8, and one of the wires is sequentially wrapped with a synthetic mica 3 and a silicon oxide fiber braided layer 4 outside the nickel-chromium positive electrode conductor 1 , high temperature resistant coating 5 and pure nickel wire braided sub-shielding layer 6.

[0025] Another kind of wire is composed of nickel-silicon negative electrode conductor 2 wrapped with synthetic mica 3, silicon oxide fiber braided layer 4, high temperature resistant coating 5 and pure nickel wire braide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com