Mop convenient in spin-drying

A mop and convenient technology, applied in the field of mops disclosed, can solve the problems of short mop lines, laborious removal of the mop head, low mopping efficiency, etc., and achieve the effects of convenient use, improved quality and efficiency, and simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

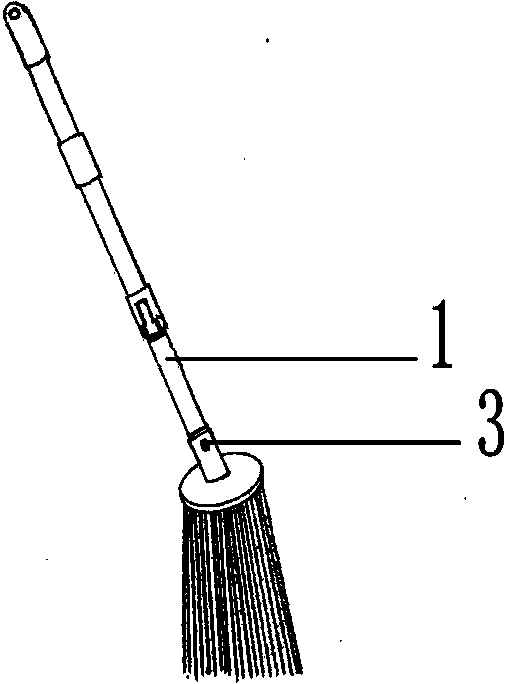

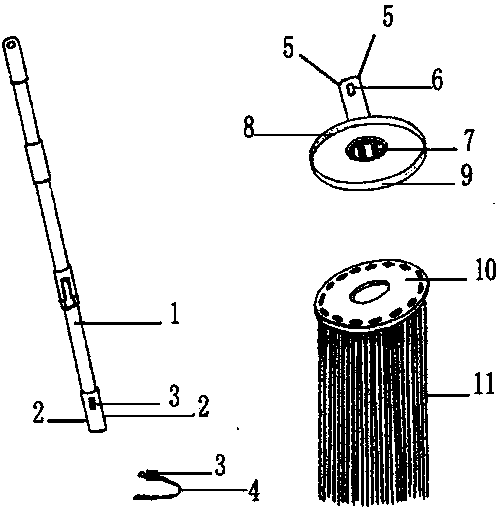

[0011] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 and figure 2 Shown is a novel long-line mop that can be used for drying, consisting of a rotating mop rod 1, a mop seat, and a wire reel. There are two limit grooves 2, U-shaped shrapnel 4 inside the cavity of the connector head, and a spring button 3 at one end of the U-shaped shrapnel 4. 3. The inner wall passing through the cavity of the connector protrudes outside. The mop head is composed of a mop seat and a mop wire reel. The upper end of the mop seat is a hollow cylindrical sleeve, and the inner wall of the sleeve has two symmetrically protruding limit positions. Rib 5 penetrates through the wall of the cylindrical sleeve and is provided with a ring button to connect the through hole 6. The lower part of the mop seat is in the shape of a plastic disk, and its edge is a circle of grooves 9 formed in the center of the disk. The groove 9 There is a circle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com