Screw conveyer for conveying insoluble sulfur

A technology of screw conveyor and sulfur, which is applied in the direction of packaging, etc., can solve the problems of difficulty in ensuring the normal transportation of insoluble sulfur, easy adhesion, material blocking, etc., and achieve the effect of ensuring normal transportation, preventing material blocking, and avoiding safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

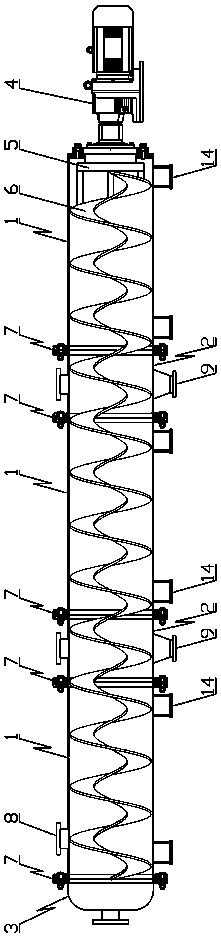

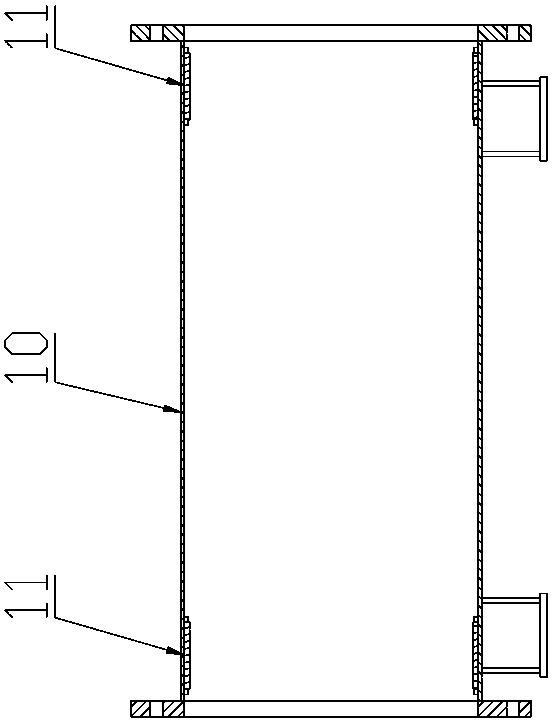

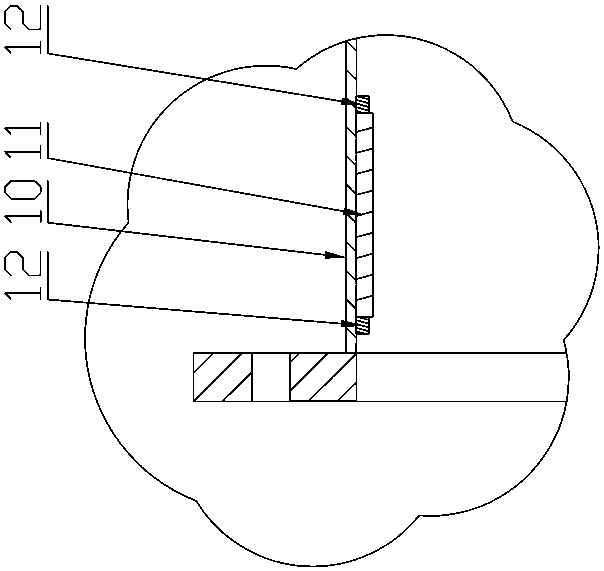

[0013] Such as figure 1 , figure 2 with image 3 As shown, the screw conveyor used for conveying insoluble sulfur includes a housing, a shaftless auger 6 and a drive mechanism 4, the housing is provided with a feeding port 8 and a feeding port 9, and the shaftless auger 6 is only composed of Constructed by screw conveying blades, the shaftless auger 6 is installed in the housing and driven by the drive mechanism 4. 5 in the figure is a connecting piece for connecting the shaft of the drive mechanism 4 and the shaftless auger 6. The screw conveyor also includes non-metallic The spacer 11 , the non-metallic spacer 11 is arranged in the casing and is arranged around the shaftless auger 6 .

[0014] The shell in this embodiment is composed of three-section long shell 1, two-section short shell 2 and head 3, and is spliced by flange structure 7, one section of long shell is provided with a feeding port, and two-section short shell Body 2 is provided with feeding port 9, that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com