Collapse rockfill instability failure simulation device

A simulation device and rockfill technology, which are applied in the field of rockfill slump simulation experiments, and can solve problems such as the discount of the actual application value of the experimental results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

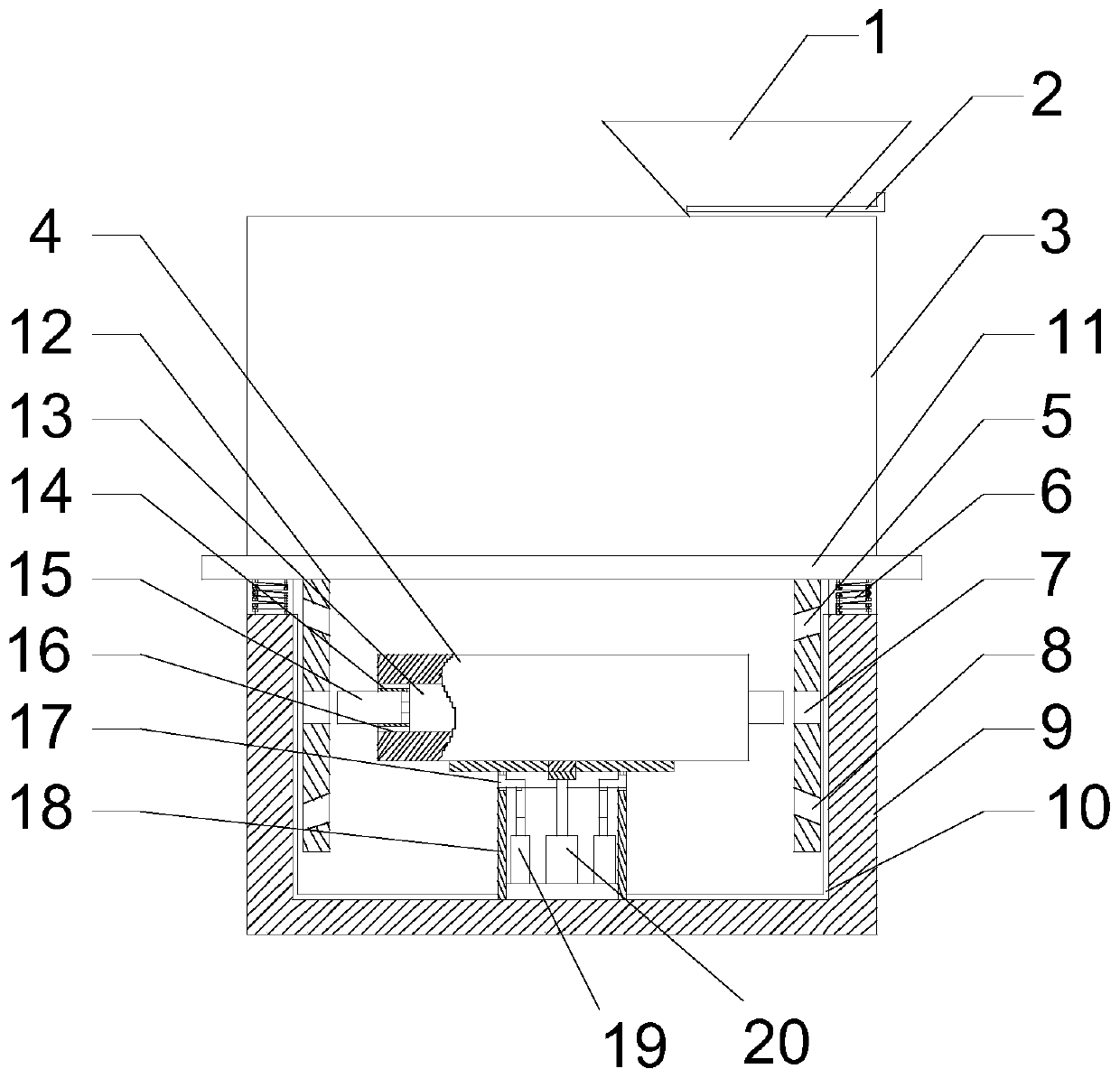

[0036] Such as Figure 1-7As shown, the present embodiment includes a simulation box 3, a base 9 positioned below the simulation box 3, a base plate 11 is provided at the bottom of the simulation box 3, and a plurality of springs 6 are respectively provided on the upper end surface of the base 9, and a plurality of The upper end of the spring 6 is connected to the lower end surface of the base plate 11, the base 9 has a cavity inside, and two hanging plates 12 are arranged on the lower surface of the base plate 11, each of the hanging plates 12 has an upper positioning The hole 5, the horizontal hole 7 and the lower positioning hole 8, and the upper positioning hole 5 and the lower positioning hole 8 are symmetrically distributed along the axis of the horizontal hole 7, and a support cylinder 18 is provided in the middle of the cavity of the base 9, and a support cylinder 18 is provided in the support cylinder 18. The top cylinder 20 and the two adjusting cylinders 19 are also...

Embodiment 2

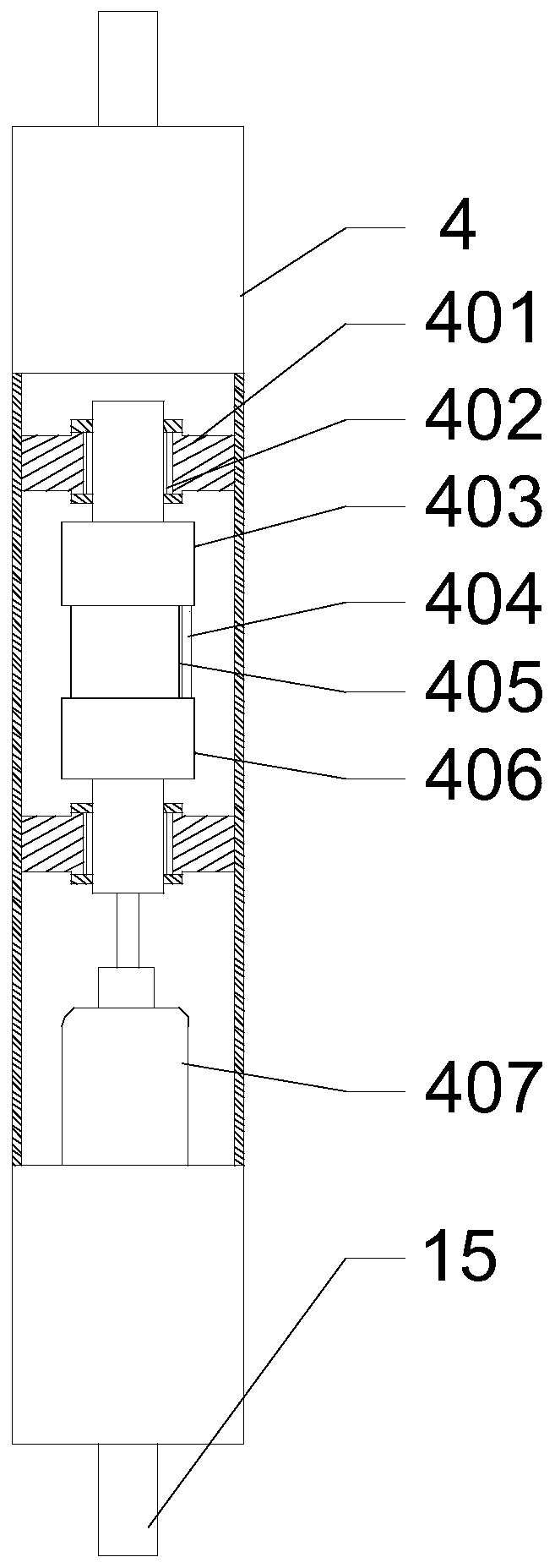

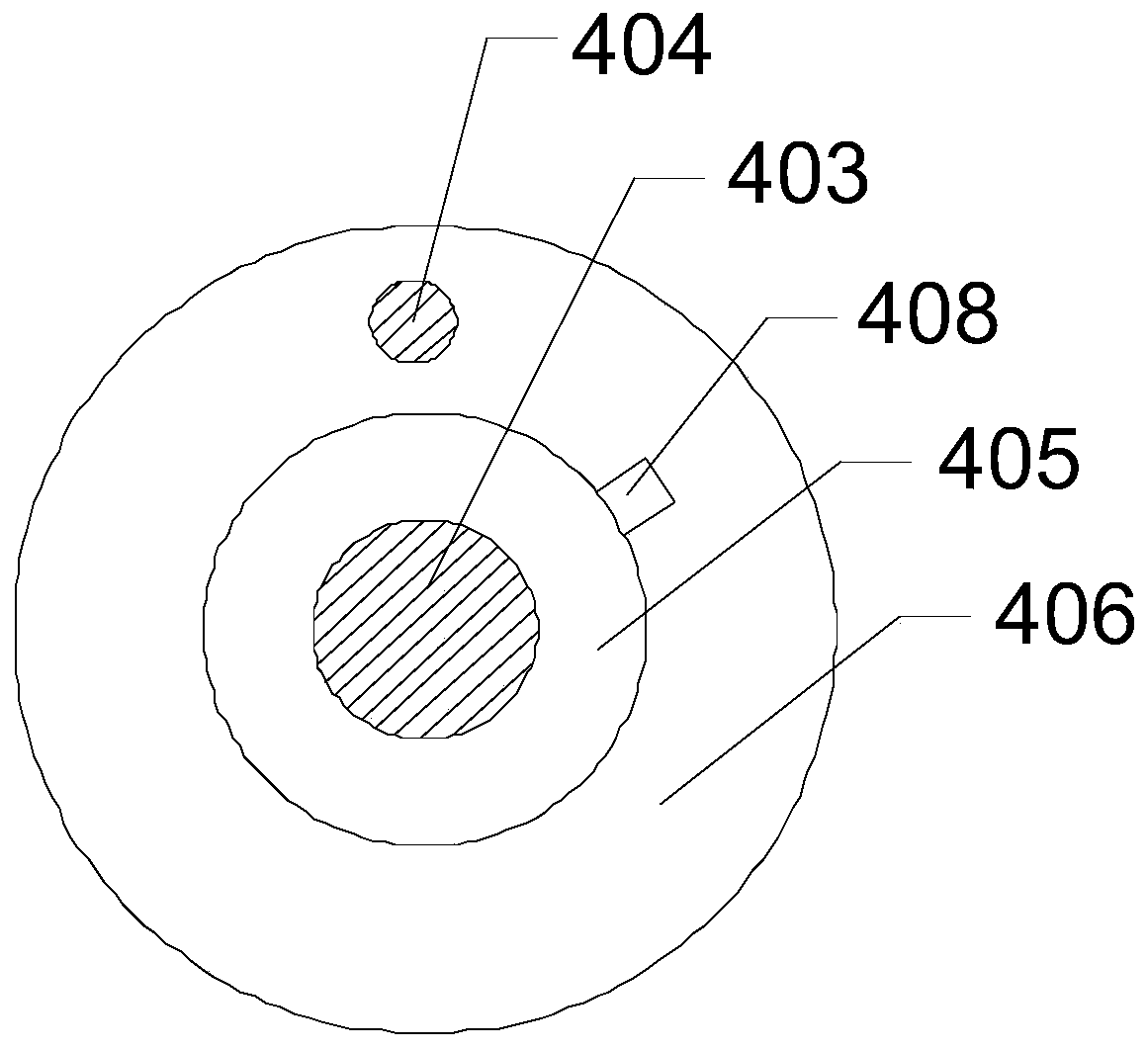

[0042] Such as figure 1 , 2 , 3, on the basis of Embodiment 1, this embodiment is provided with a cylindrical cavity inside the vibrating cylinder 4, and a motor 407 is provided along the axial direction of the cavity, and the output end of the motor 407 is A rotating shaft is provided, and two clamping plates 401 are arranged on the inner peripheral wall along the axial direction of the cavity, and a through hole is opened in the middle of each of the clamping plates 401, and bearings are respectively provided on both sides of the through hole, The outer peripheral wall of the rotating shaft is in contact with the inner peripheral walls of the four bearings respectively, and a static eccentric wheel 403 and a static eccentric wheel 406 are respectively fixed on the outer peripheral wall of the rotating shaft, and the static eccentric wheel 403 and the static eccentric wheel 406 are placed on Between the two clamping plates 401 , a moving eccentric 405 is rotated on the outer...

Embodiment 3

[0048] Such as Figure 7 As shown, this embodiment includes a cover plate 301 and four columns 304 respectively located on the lower surface of the cover plate 301, and also includes a terrain simulation plate 309, an active push-pull plate 314 and a door closer 315, and the adjacent two described The side walls of the columns 304 are provided with adjustment blocks 311, and each adjustment block 311 is provided with inferior arc grooves 312. The two side walls at one end of the terrain simulation board 309 are respectively hinged with the remaining two side walls of the columns 304. The two side walls of the other end of the terrain simulation board 309 are respectively provided with screw rods, and the screw rods move through the inferior arc groove 312 on the same side as the screw rods, and a matching locking head 313 is provided on the outer end of the screw rods, The cover plate 301 is provided with an open opening for the passing of the block stone 303, the housing of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com