A method for precise positioning of coal shearer in 3D model of coal seam in working face

A three-dimensional model and precise positioning technology, applied in the precise positioning of the three-dimensional model, and the precise positioning of the shearer in the three-dimensional model of the coal seam of the working face, to achieve the effect of wide practicability, precise positioning, and interactive perception.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

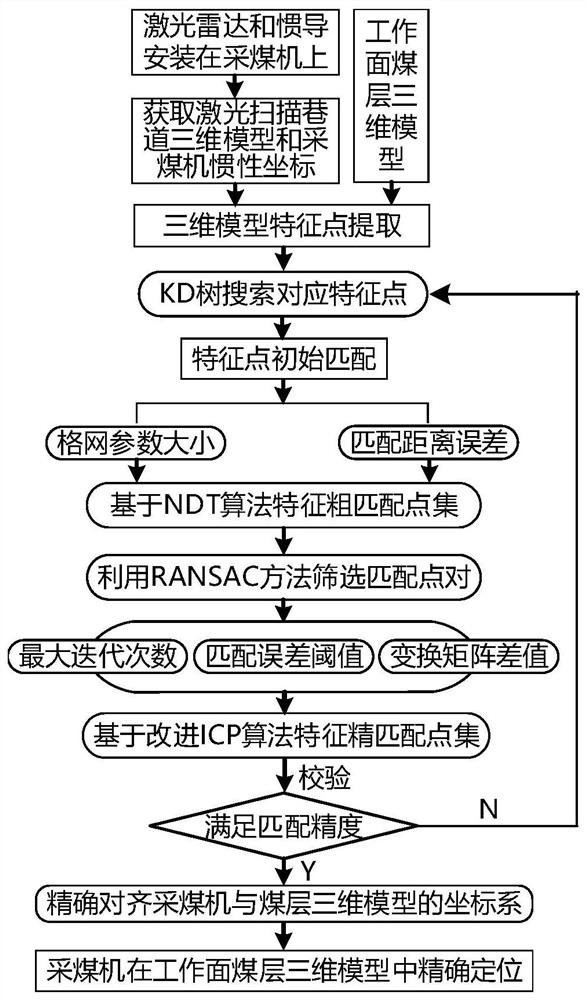

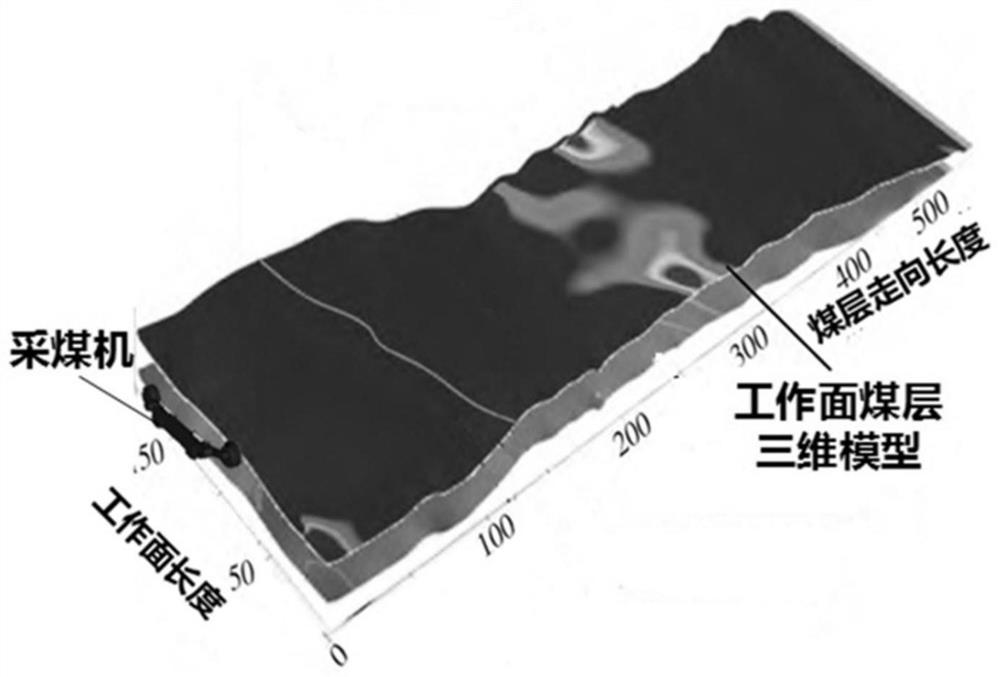

[0036] like figure 1 As shown, the precise positioning method of the shearer in the three-dimensional model of the coal seam of the working face, through the precise matching of the three-dimensional model of the laser scanning roadway and the three-dimensional model of the coal seam of the working face, realizes the precise positioning of the shearer in the three-dimensional model of the coal seam of the working face, Specific steps include:

[0037] (1) Install the laser radar and inertial navigation on the coal shearer. When the coal shearer cuts to the end of the working face, the laser radar starts to scan quickly to obtain the 3D point cloud data of the roadway laser scanning, and uses the Gaussian filter method to analyze the The roadway laser scanning 3D point cloud data is denoised and filtered, and the roadway laser scanning 3D model is est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com