LED device, fabrication method thereof and display panel

A technology of LED devices and display panels, which is applied in the direction of semiconductor devices, instruments, electrical components, etc., can solve the problem that the transmittance cannot meet the user's transmittance requirements, and achieve the effect of simple and transparent display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

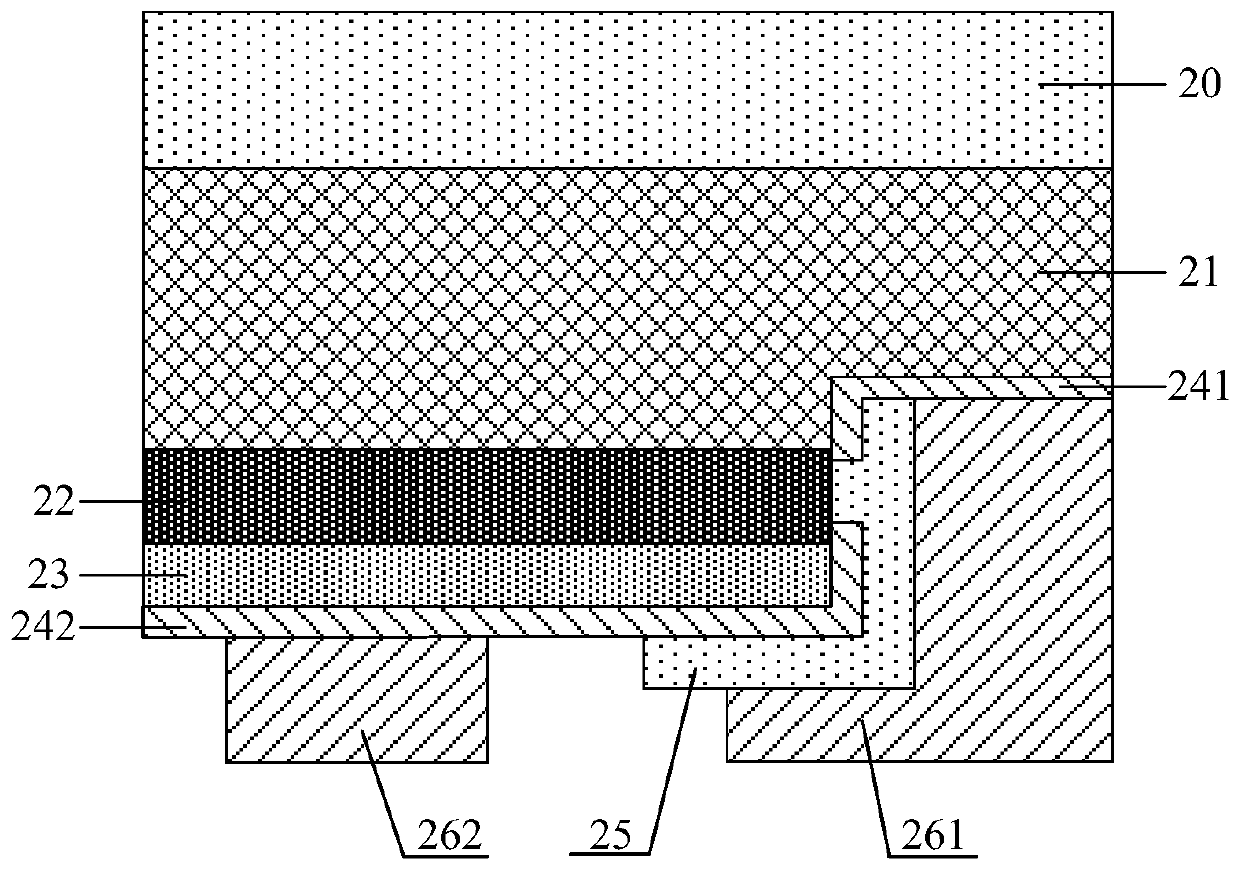

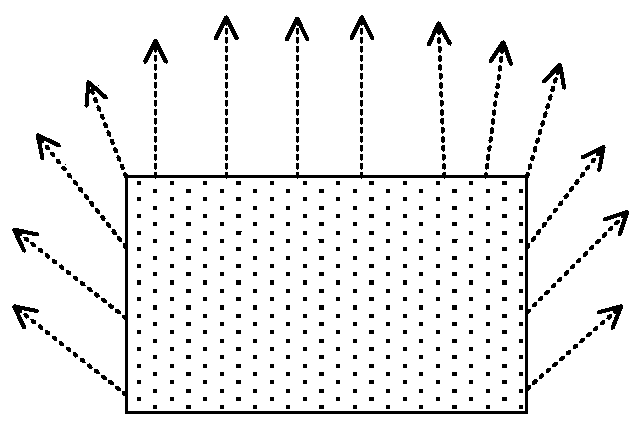

[0050] Figure 4 It is a schematic structural diagram of the LED device according to the first embodiment of the present invention. Figure 5 for Figure 4 Schematic diagram of the light output of the LED device shown. Such as Figure 4 As shown, the LED device includes a device structure layer disposed on a substrate 20 , and the device structure layer includes a first semiconductor layer 21 , a light-emitting functional layer 22 and a second semiconductor layer 23 disposed on the substrate 20 in sequence. The device structure layer also includes a first electrode 261 and a second electrode 262 . The first electrode 261 is electrically connected to the first semiconductor layer 21 , and the second electrode 262 is electrically connected to the second semiconductor layer 23 . The materials of the first electrode 261 and the second electrode 262 are both transparent materials. The LED device also includes a reflective layer 30 disposed on the peripheral side of the device ...

no. 2 example

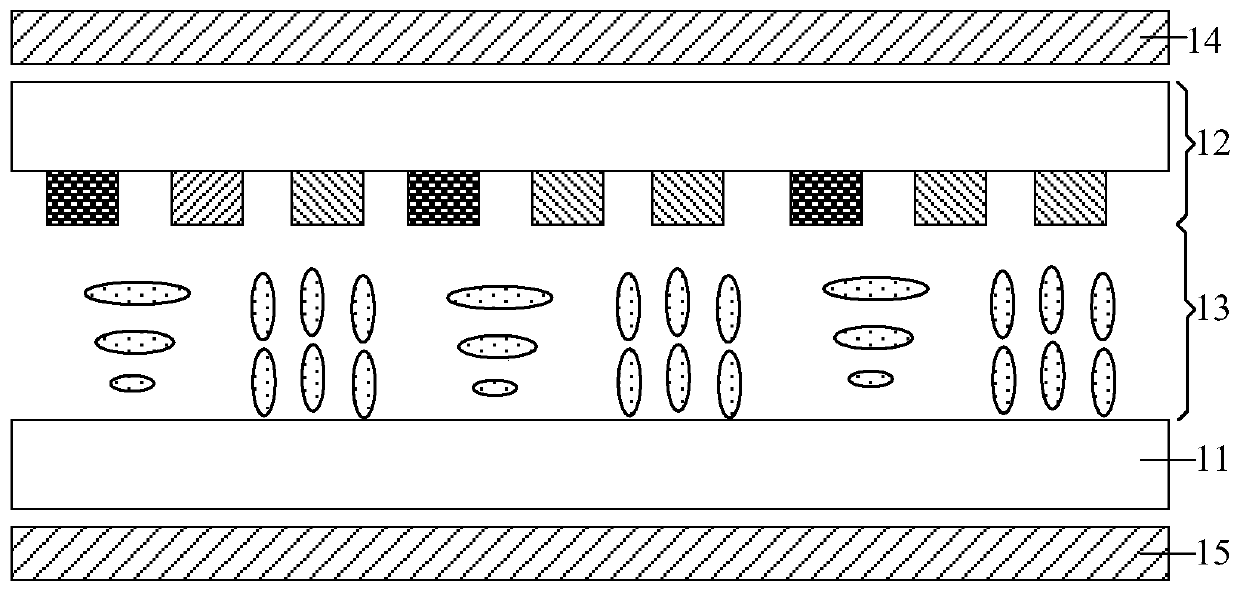

[0068] Figure 7 It is a schematic structural diagram of the display panel according to the second embodiment of the present invention. Such as Figure 7 As shown, the display panel includes a transparent first substrate 50 and a plurality of LED devices 60 according to the first embodiment of the present invention disposed on the first substrate 50 .

[0069] In order to realize the transparency of the first substrate 50, the first substrate 50 may include a transparent substrate, such as a glass substrate or the like. The first substrate 50 may further include a first control wiring and a second control wiring disposed on a side of the transparent substrate facing the LED device 60 . The first control wiring is used to electrically connect with the first electrode of the LED device and provide a corresponding working voltage to the first electrode, and the second control wiring is used to electrically connect to the second electrode of the LED device and provide a correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com