Parallel wiring groove

A wiring trough, integrated technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of uneven torque, easy breakdown, poor insulation performance and sealing performance, etc., to improve the service life and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings.

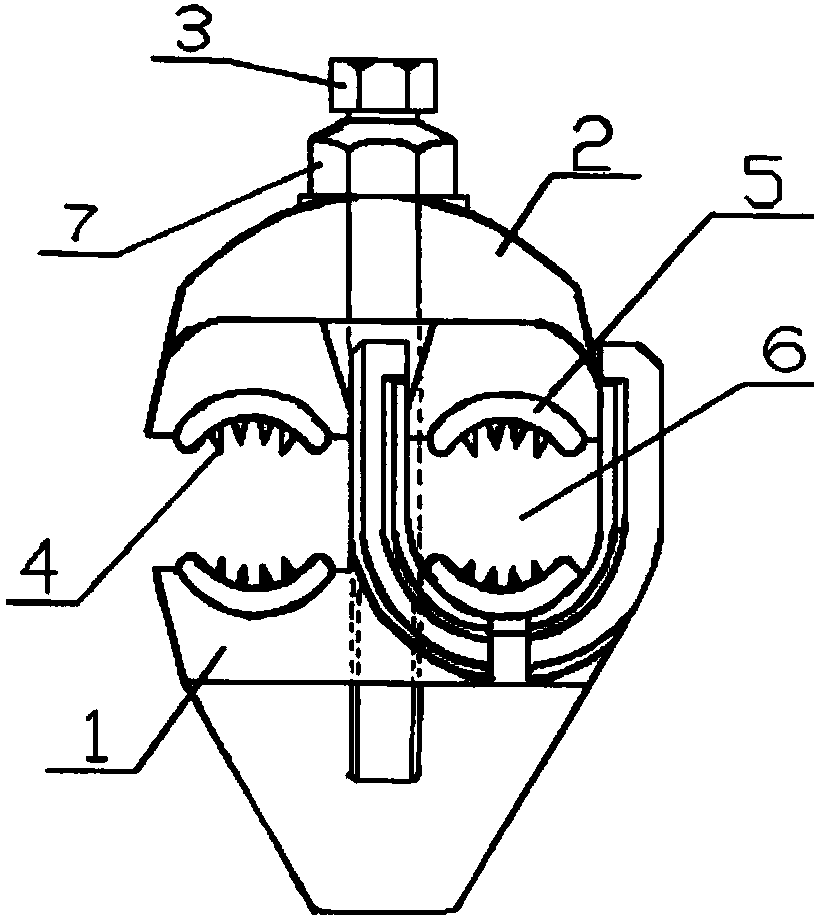

[0008] see figure 1 , the present invention includes a main body lower cover 1 of a parallel wiring trough and an upper cover 2 of a main body of a parallel wiring trough, the lower cover 1 of a main body of a parallel wiring trough and the upper cover 2 of a main body of a parallel wiring trough are connected as one by bolts 7, and a torque cap 3 is provided on the bolts 7 , rotating the torque cap 3 can clamp or loosen the lower cover 1 of the main body of the parallel wiring trough and the upper cover 2 of the main body of the parallel wiring trough. The left one and the right one are respectively provided with two arc-shaped insulated copper-toothed sheaths 5, forming two parallel wiring grooves 6, and copper teeth 4 are arranged on the outer side of the copper-toothed sheaths.

[0009] The copper tooth 4 and the copper tooth sheath 5 of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com