Mobile phone, mobile phone rear shell with touch pad operation function and manufacturing method thereof

A technology of operation function and mobile phone back shell, which is applied in the field of intelligent terminal design, can solve the problems of low manufacturing process efficiency, short injection molding cycle, and non-zero-defect production, and achieve compact structure, anti-aging performance, and improved manufacturing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

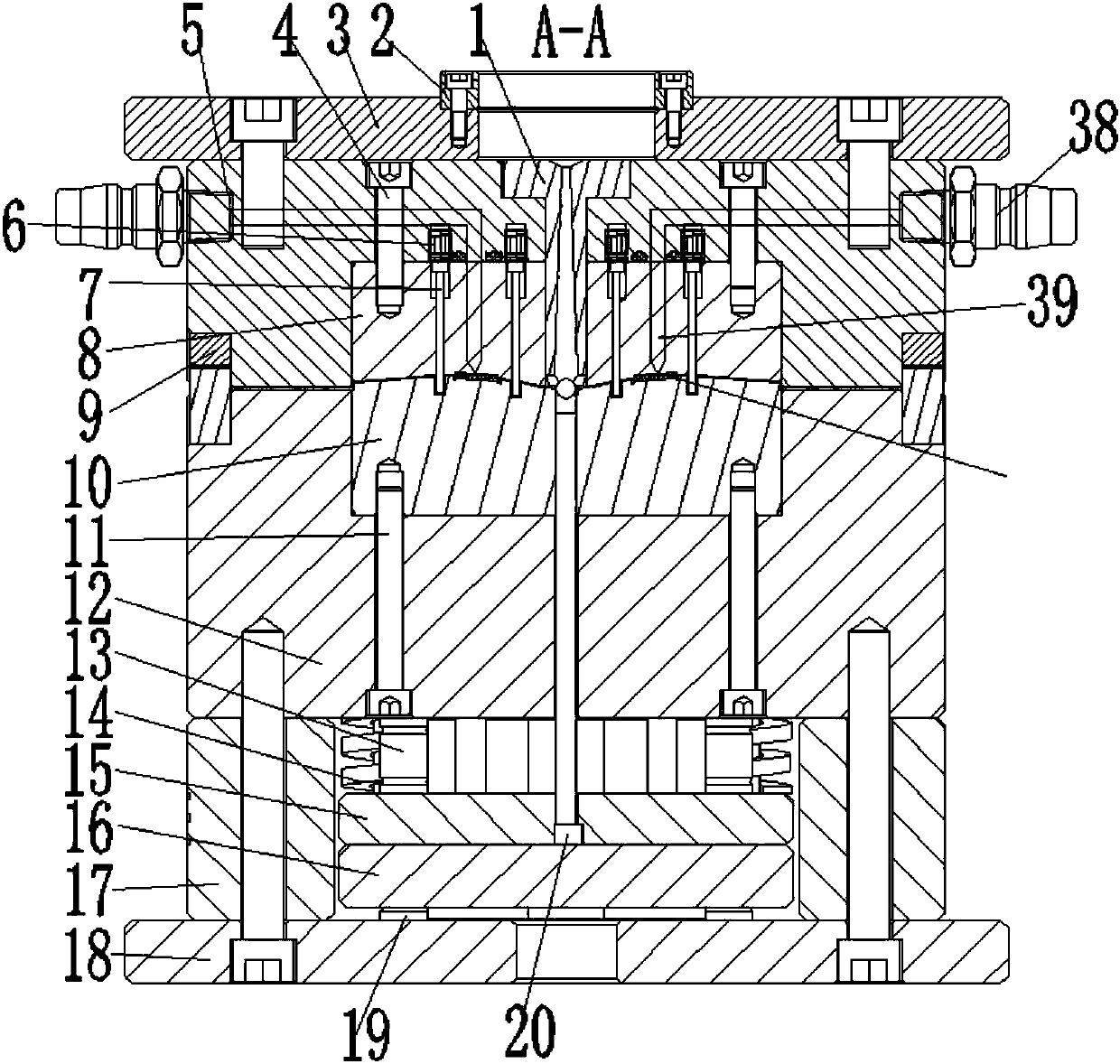

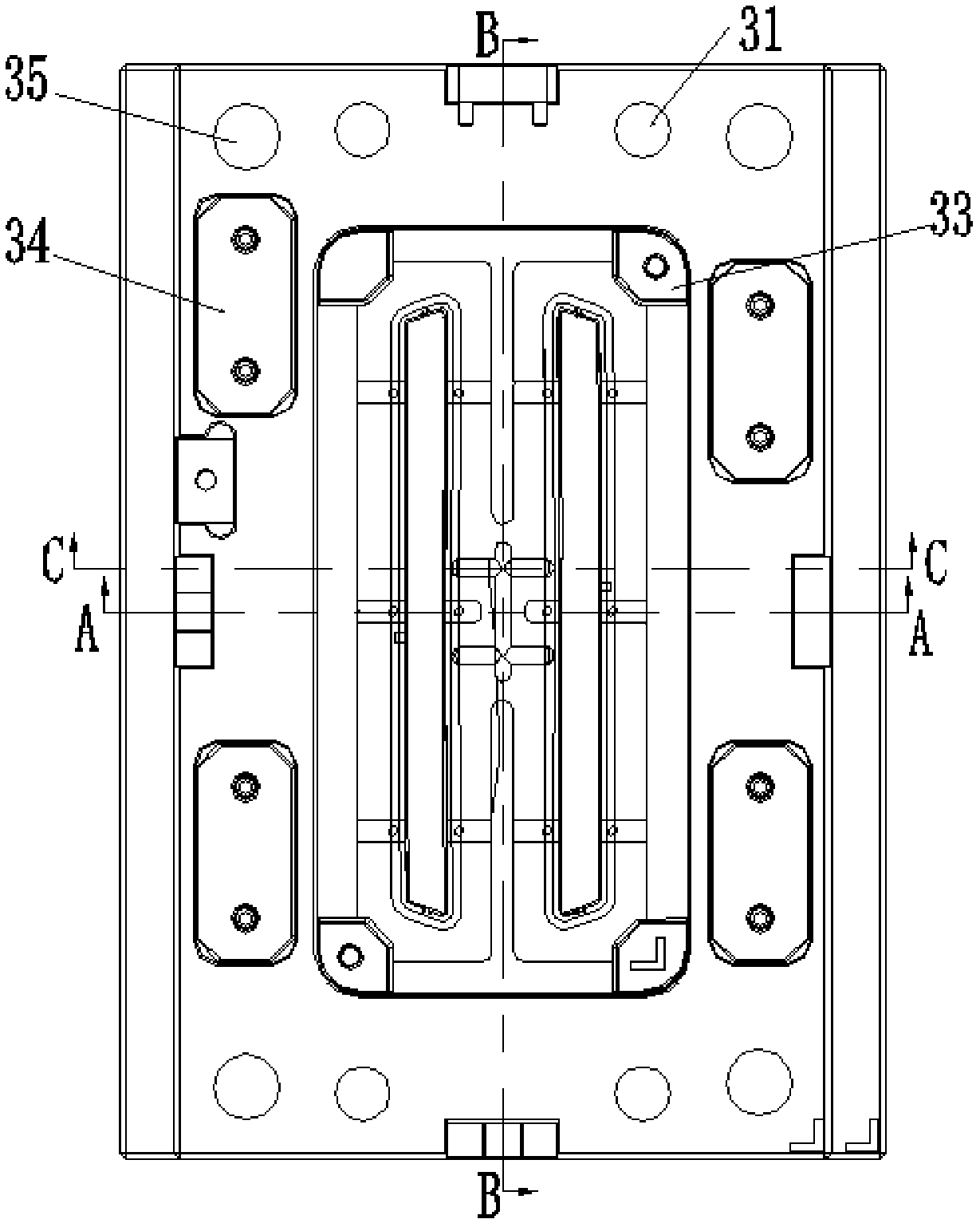

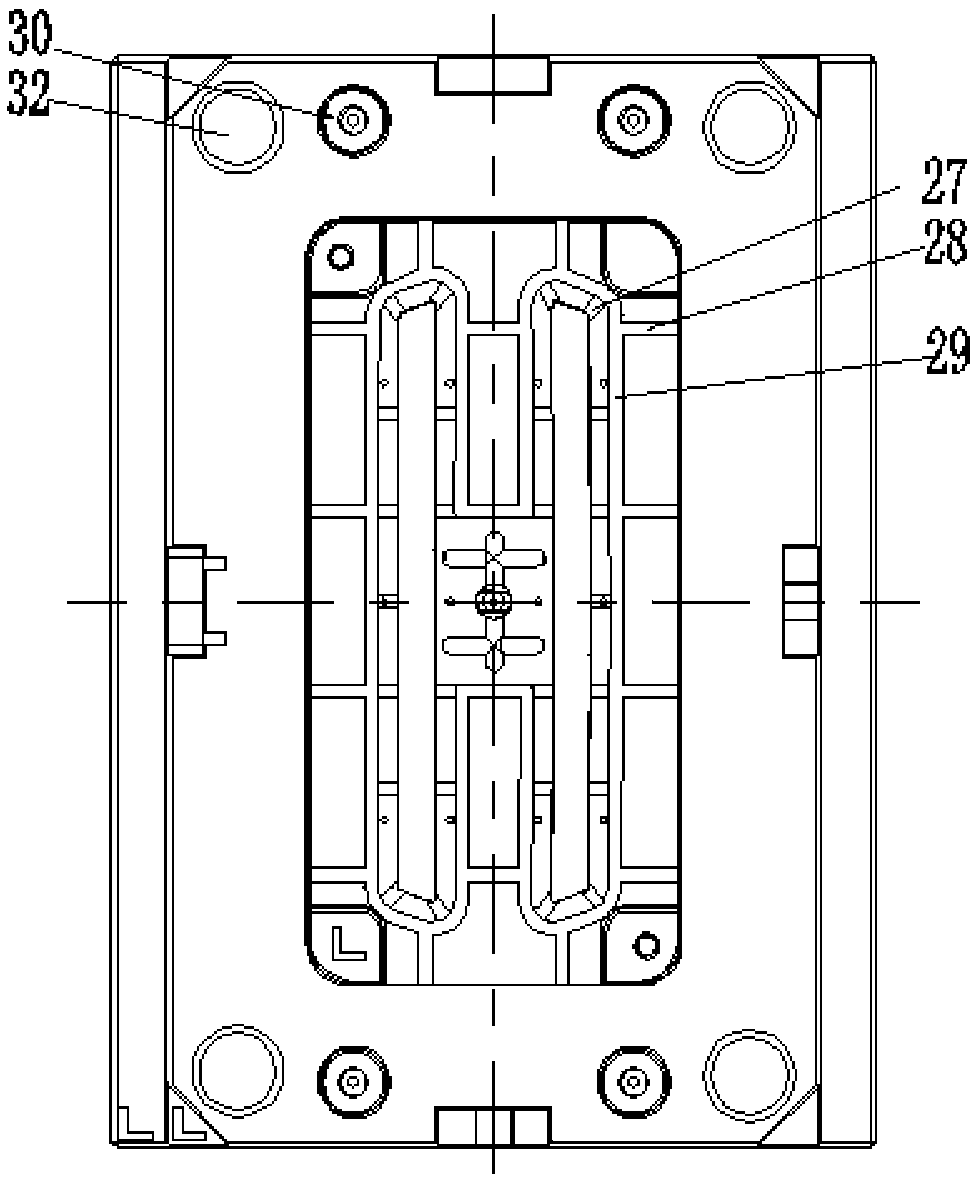

[0025] Figure 1-6 Shown is the relevant explanatory figure of the present invention; Figure 1-6 As shown, a touch panel IMR process injection mold manufacturing, said:

[0026] The mold structure adopts a two-plate mold cold runner injection molding structure, and the layout is one mold with two cavities. The molded parts adopt the insert insert method, mainly including figure 1 The cavity insert 8 and the core insert 10 shown in the cross-section of A-A in the middle, in order to ensure the accuracy of the reset when the cavity insert 8 and the core insert 10 are opened and closed, a matching positioning feature between the two is specially designed Mo Ren Hukou 33.

[0027] The mold pouring system adopts the cold runner latent gate pouring method, such as Figure 5 As shown in the cross-sectional view of C-C, a single product adopts the double gate casting method, and the gate of the latent gate is designed on the gate thimble 26, and the gate diameter is The latent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com