pneumatic tire

A technology of pneumatic tires and sipes, which is applied to road vehicle tires, off-road vehicle tires, tire parts, etc., can solve the problem of rigidity reduction and achieve the effect of ensuring grounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

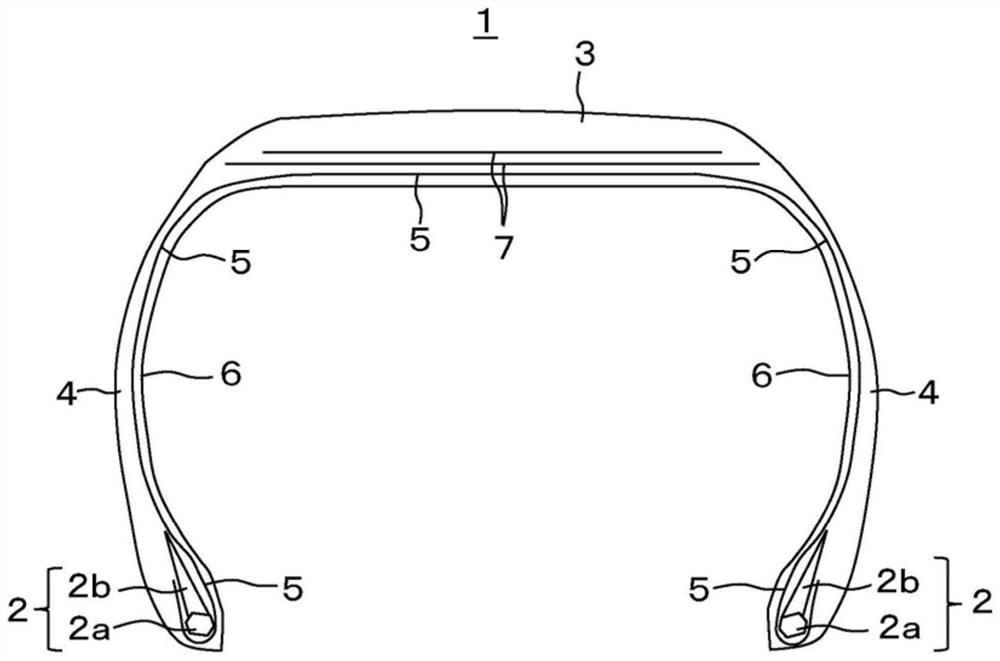

[0015] like figure 1 As shown by way of example, bead portions 2 are provided on both sides in the tire width direction of the pneumatic tire 1 . The bead portion 2 includes: a bead core 2a formed of a steel wire wound in a circular shape; and a rubber bead apex 2b provided radially outside the bead core 2a. A carcass ply 5 is bridged over the bead portions 2 on both sides in the tire width direction. The carcass ply 5 is a sheet-like member in which a plurality of cords arranged in a direction perpendicular to the tire circumferential direction are covered with rubber. The carcass ply 5 forms the skeleton shape of the pneumatic tire 1 between the bead portions 2 on both sides in the tire width direction, and is folded around the bead portion 2 from inside to outside in the tire width direction to wrap the bead portion 2 . A sheet-shaped inner liner 6 made of rubber with low air permeability is pasted inside the carcass ply 5 .

[0016] One or more layers of the belt 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com