Multi-degree-of-freedom installation transport vehicle and method for transporting and installing model by adopting installation transport vehicle

A technology of transport vehicles and degrees of freedom, which is applied in the directions of transportation and packaging, multi-axis trolleys, trolleys, etc., can solve the problems that restrict the smooth development of test model preparation work, lack of effective safety measures, and large safety hazards, etc., to achieve The installation process is safe, reliable and convenient, avoiding model damage to the balance and ensuring the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

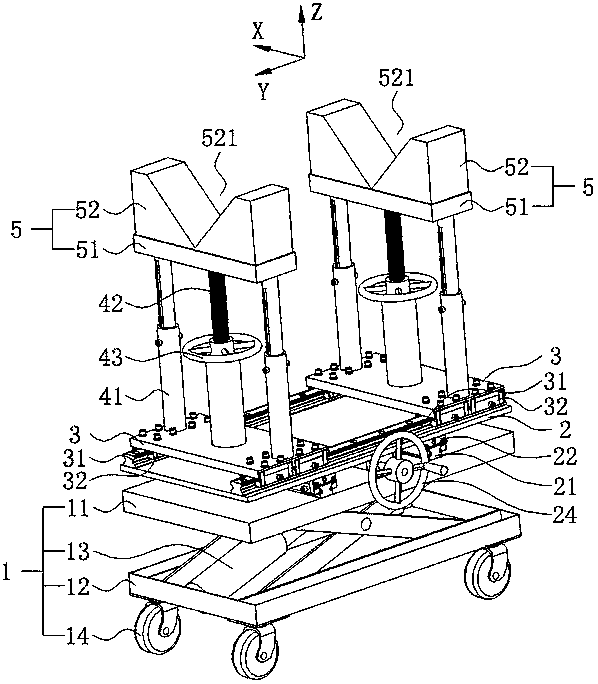

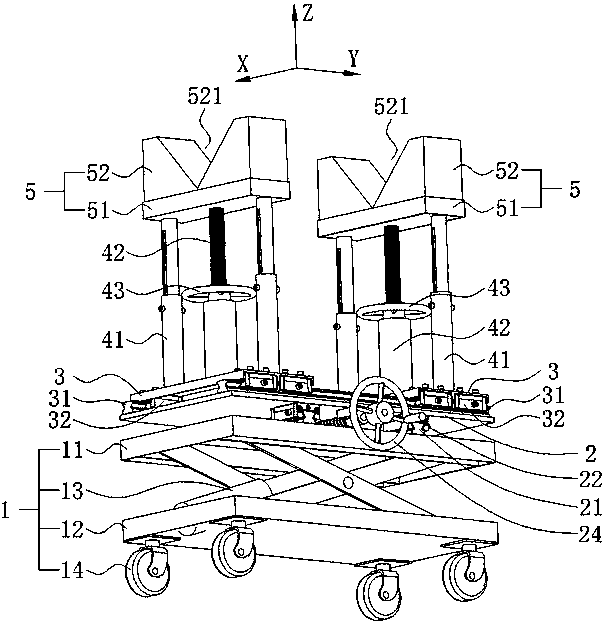

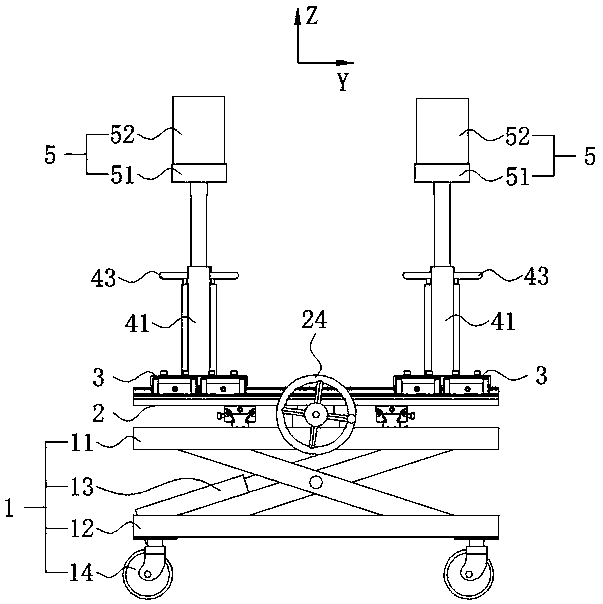

[0050] Such as Figure 1 to Figure 10 As shown, a multi-degree-of-freedom installation transport vehicle in this embodiment includes a cart 1 distributed from bottom to top, an X-direction support 2, two Y-direction supports 3, and two support blocks 5; wherein, The X-direction support 2 can be assembled on the cart 1 through the X-direction adjustment mechanism to move in the X direction; the two Y-direction supports 3 can be assembled on the X-direction support 2 through the Y-direction adjustment mechanism to move in the Y direction , and the distance between the two Y-direction supports 3 can be adjusted through the Y-direction adjustment mechanism; the two support blocks 5 can be assembled on the two Y-direction supports 3 through the Z-direction adjustment mechanism, respectively, and can be moved in the Z direction through the Z-direction adjustment mechanism. The mechanism can adjust the height of the two supporting blocks 5 asynchronously.

[0051] In this embodiment...

Embodiment 2

[0063] The method for transporting and installing the wind tunnel test model by using the installation transport vehicle of Embodiment 1 comprises the following steps:

[0064] Step 1. Adjust the distance between the two Y-direction supports 3 through the Y-direction adjustment mechanism, so that the distance between the two Y-direction supports 3 is suitable for placing the model;

[0065] Step 2, placing the model on the two supporting blocks 5;

[0066] Step 3. Transfer the model to the required installation location (such as near the balance of the test) by installing the transport vehicle;

[0067] Step 4. Initially adjust the installation orientation of the model by installing the transport vehicle;

[0068] Step 5. Precisely adjust the installation orientation of the model: accurately adjust the position of the model in the X direction through the X-direction adjustment mechanism, accurately adjust the position of the model in the Y direction through the Y-direction ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com