Parent-subsidiary mounting ship and application thereof to offshore wind turbine mounting

A technology for installing ships and mother ships, which is applied to the installation/support of wind turbine configurations, hulls, motor vehicles, etc. It can solve the problems of unfavorable control period, inconvenient movement, high cost, etc., and achieve the effect of improving transportation capacity and installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

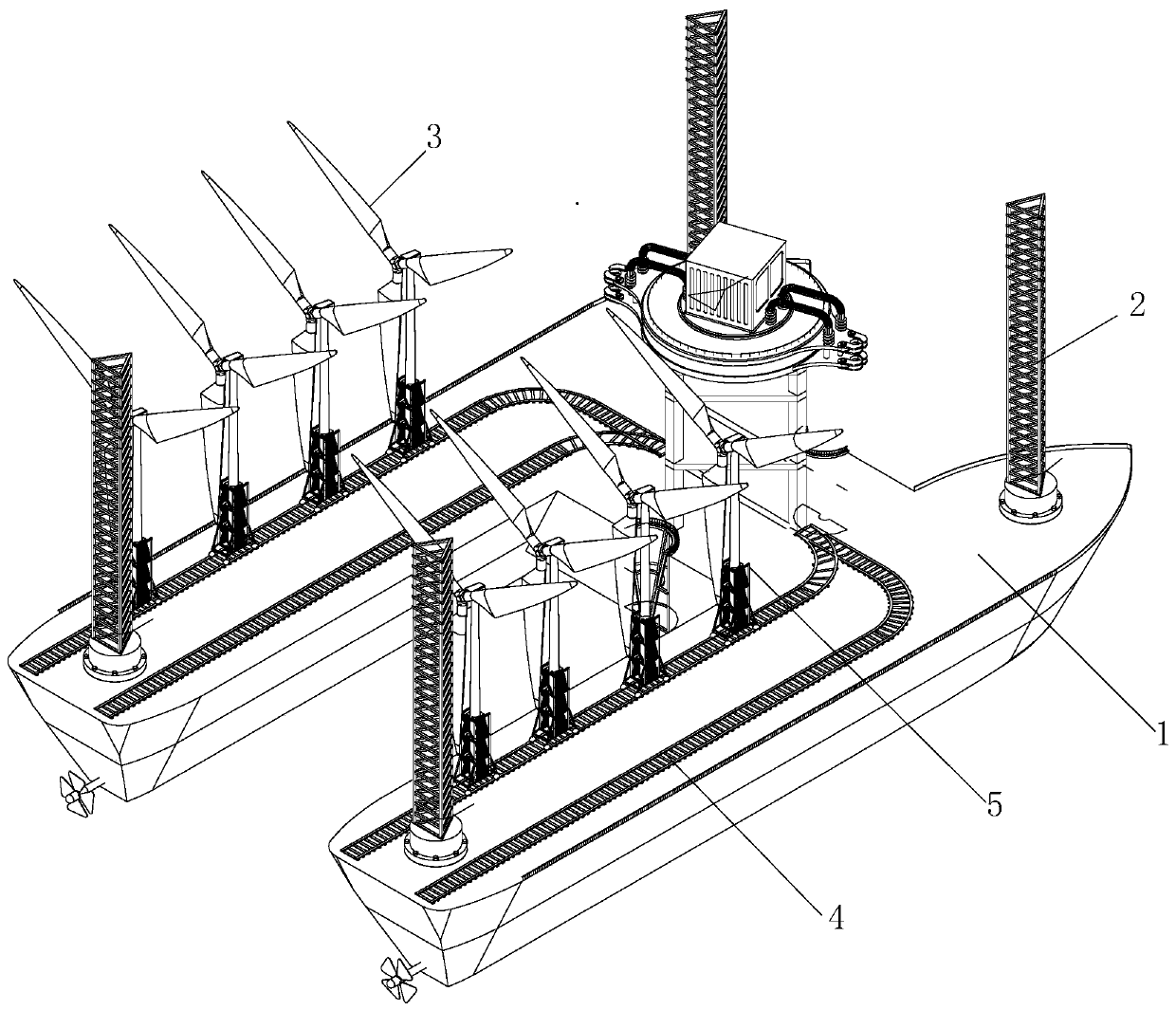

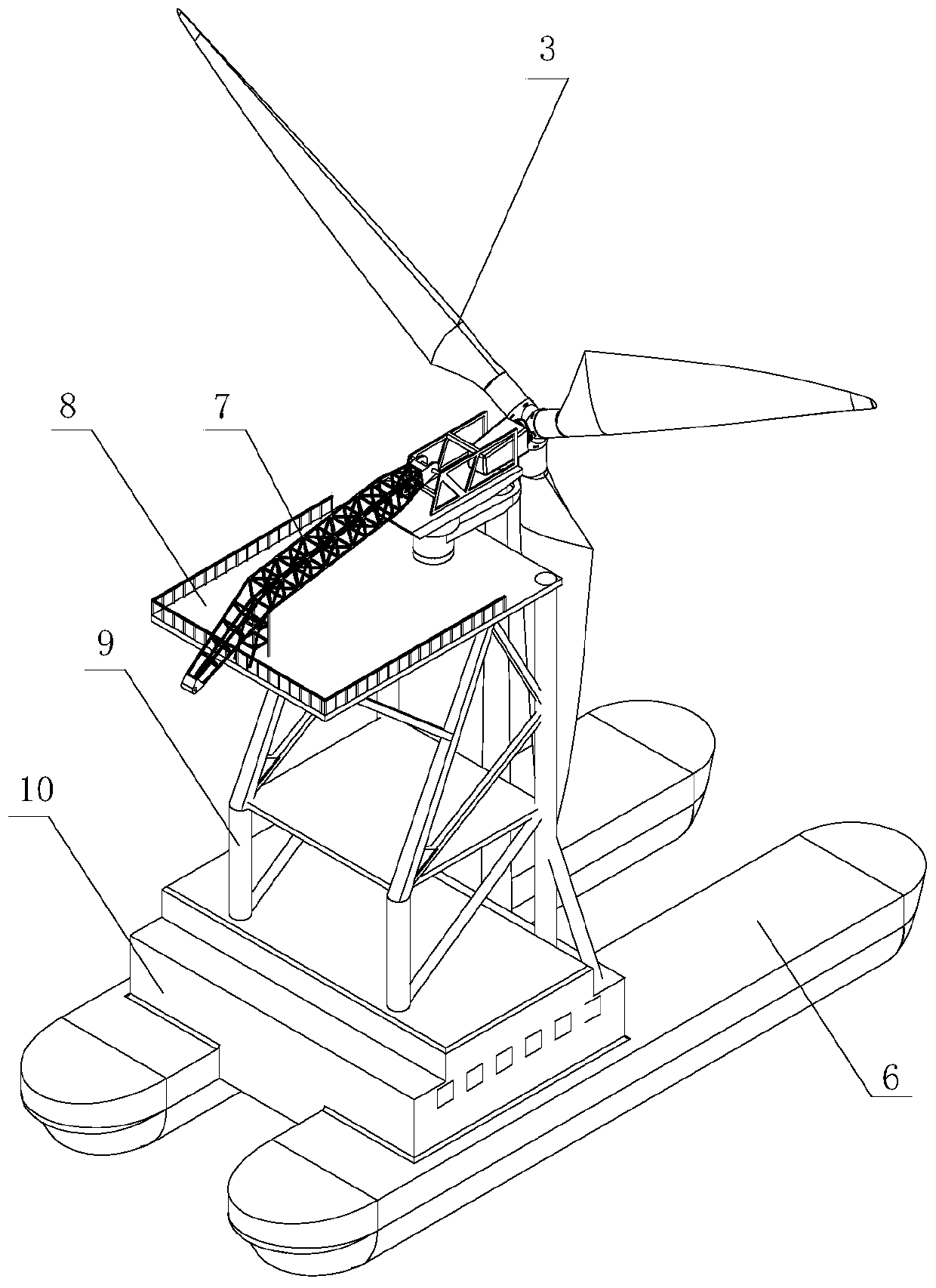

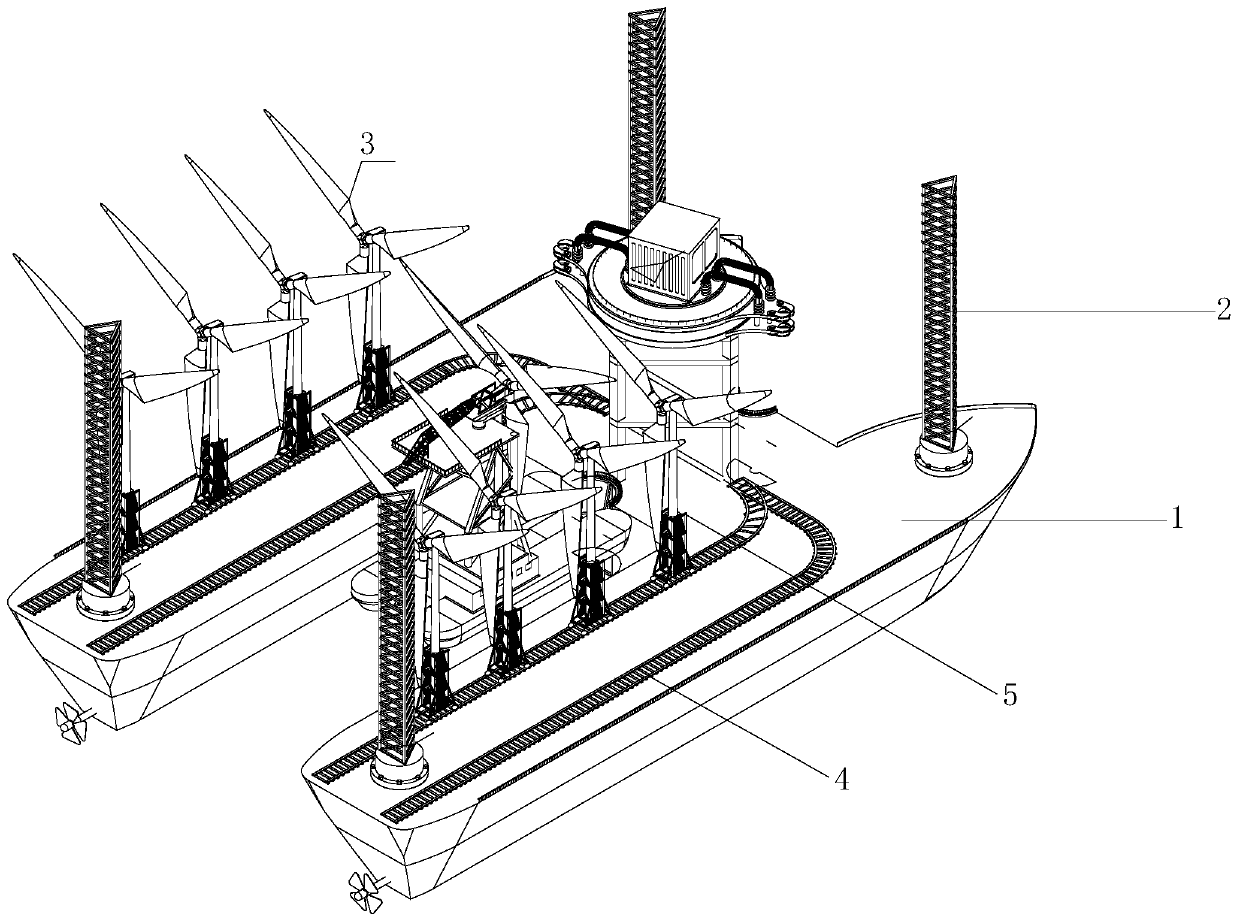

[0018] The invention provides a mother-child installation ship, which is composed of a U-shaped mother ship and a catamaran-shaped daughter ship, such as figure 1 As shown, the mother ship includes a U-shaped hull 1, the surface of the U-shaped hull 1 is provided with a sliding track system 4, the fan 3 is placed on the sliding track system 4, and a rotating lifting system 5 is installed on the periphery of the fan 3. First trusses 2 are installed on the four corners of the hull 1 . like figure 2 As shown, the sub-ship includes two single hulls 6 and a connecting body 10 connecting the two single hulls 6. A second truss 9 is installed on the connecting body 10, and a crane platform 8 is installed on the top of the second truss 9. The crane platfo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap