Heat pump type washing and drying integral machine, and evaporator cleaning method and device thereof

A technology for cleaning devices and evaporators, which is applied in the field of washing machines and can solve problems such as easy clogging of the evaporator surface and affecting drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

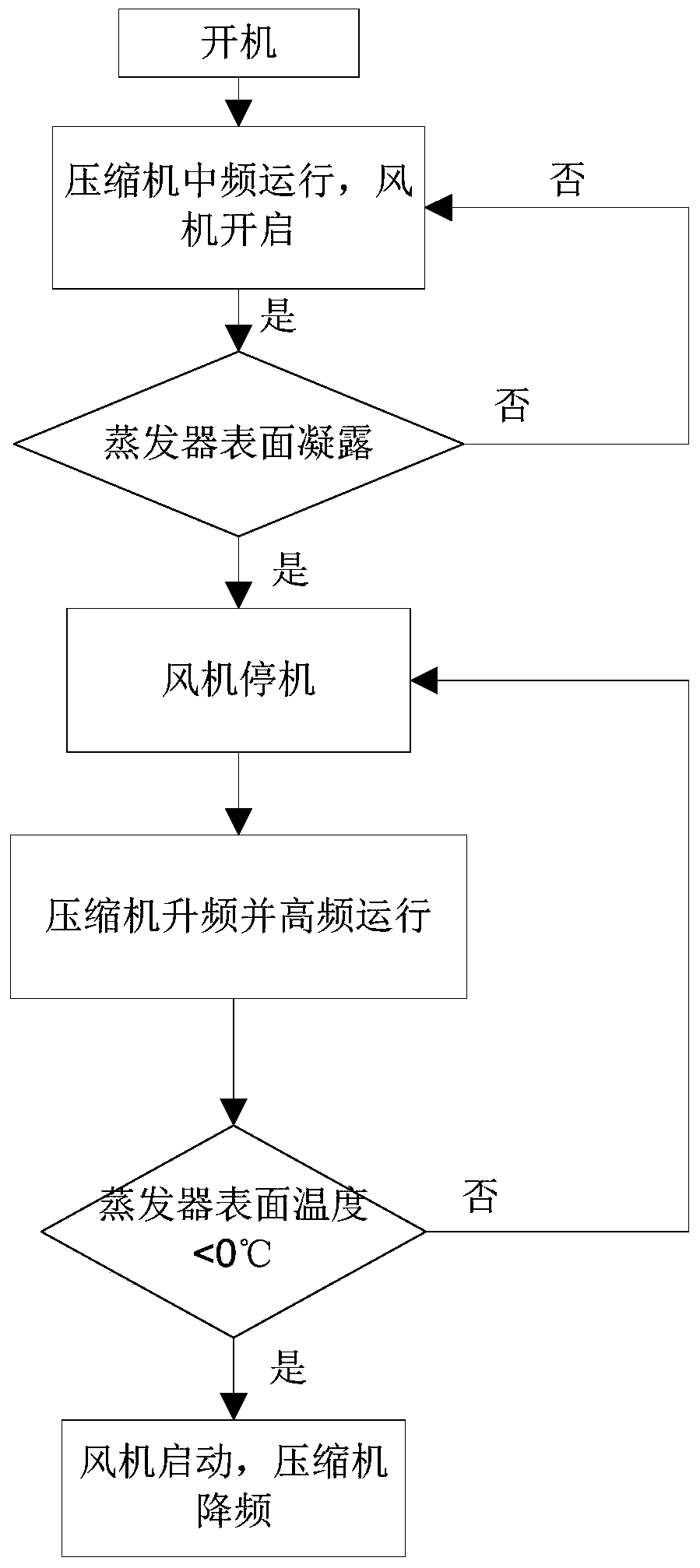

[0045] In order to solve the above problems, this embodiment provides a method for cleaning the evaporator of a heat pump type washing and drying machine, such as figure 1 As shown, the cleaning method includes the following steps:

[0046] Step S1, the evaporator enters the cleaning mode, turns on the fan and keeps the compressor running at a frequency of 45-60Hz.

[0047]Receive the cleaning command of the evaporator, switch the current operation mode of the heat pump washing and drying machine to the self-cleaning mode; or set the cleaning trigger mechanism in the heat pump washing and drying machine, calculate the total running time, wait for the heat pump washing and drying machine After the machine running time reaches the target time, it will automatically switch from the current running mode to the evaporator cleaning mode. Wherein, the operation target duration of the cleaning trigger mechanism is the time set by the user in the heat pump washer-dryer system. After ...

Embodiment 2

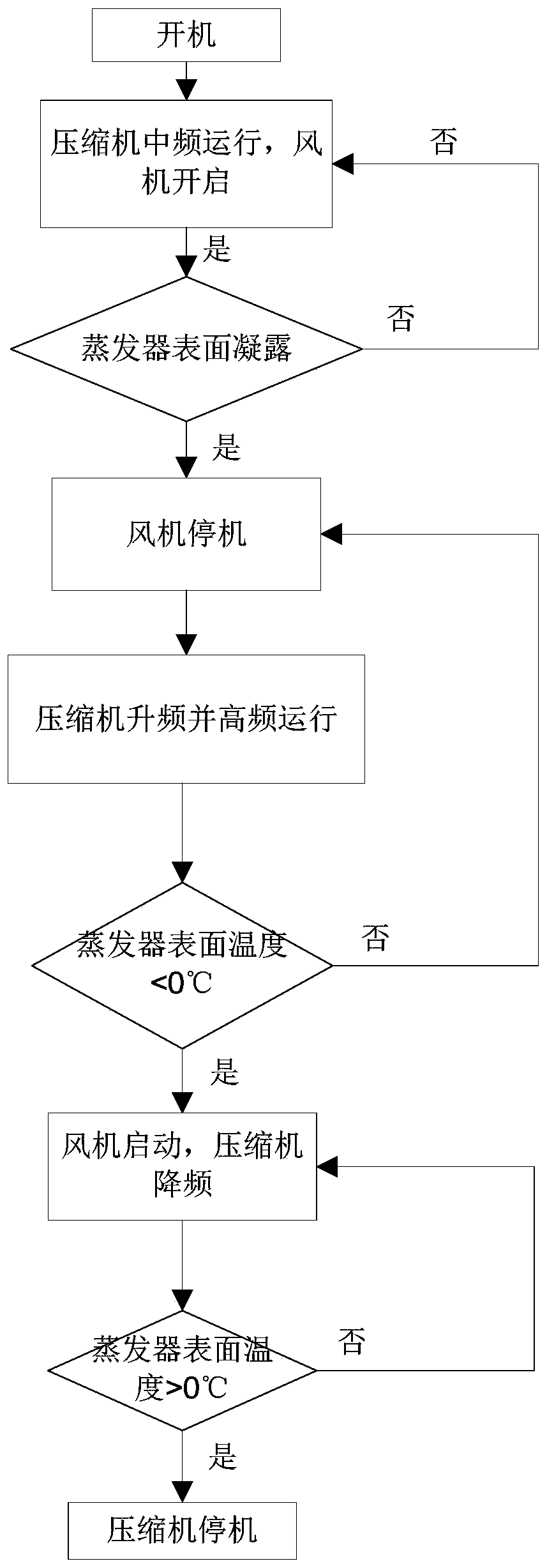

[0054] This embodiment provides a method for cleaning the evaporator of a heat pump type washing and drying machine, such as figure 2 As shown, the cleaning method includes the following steps:

[0055] Step S1, the evaporator enters the cleaning mode, turns on the fan and keeps the compressor running at a frequency of 45-60Hz;

[0056] Step S2, when the surface of the evaporator is condensed, the fan is turned off, and the compressor is controlled to increase the frequency and continue to run;

[0057] Step S3, when the surface temperature of the evaporator is lower than 0°C, turn on the fan, and control the compressor to continue running after down-frequency;

[0058] Step S4, when the surface temperature of the evaporator is greater than 0°C, exit the evaporator cleaning mode and turn off the compressor.

[0059] Compared with embodiment 1, this embodiment is different in that step S4 is added, wherein steps S1, S2 and S3 can refer to the specific scheme of embodiment 1 ...

Embodiment 3

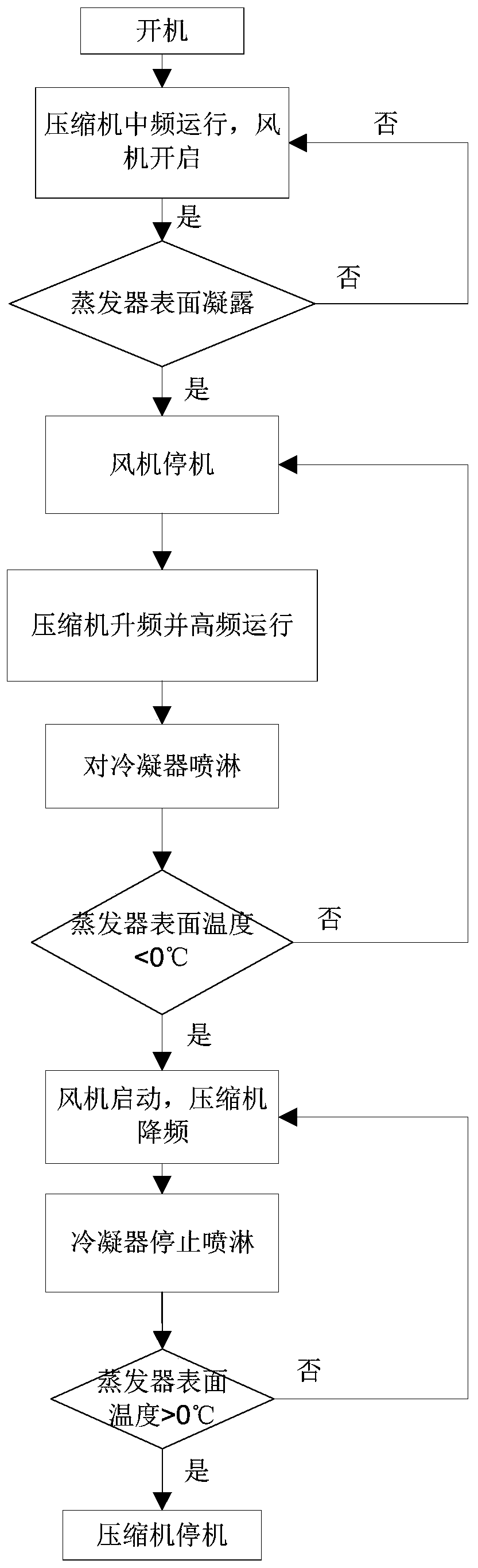

[0063] This embodiment provides a method for cleaning the evaporator of a heat pump type washing and drying machine, such as image 3 As shown, the cleaning method includes the following steps:

[0064] Step S1, the evaporator enters the cleaning mode, turns on the fan and keeps the compressor running at a frequency of 45-60Hz;

[0065] Step S2, when the surface of the evaporator is condensed, the fan is turned off, and the compressor is controlled to increase the frequency and continue to run;

[0066] Step S200, spraying and cooling the condenser;

[0067] Step S3, when the surface temperature of the evaporator is lower than 0°C, turn on the fan, and control the compressor to continue running after down-frequency;

[0068] Step S300, stop spraying the condenser.

[0069] Step S4, when the surface temperature of the evaporator is greater than 0°C, exit the evaporator cleaning mode and turn off the compressor.

[0070] Compared with embodiment 1 and embodiment 2, the diffe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap