Prefabricated and assembled pipelines for underground comprehensive pipe gallery

A prefabricated assembly and integrated pipe gallery technology, which is applied to underwater structures, buildings, artificial islands, etc., can solve the problems that modern subways cannot be built, and modern underground comprehensive pipe galleries cannot be built.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

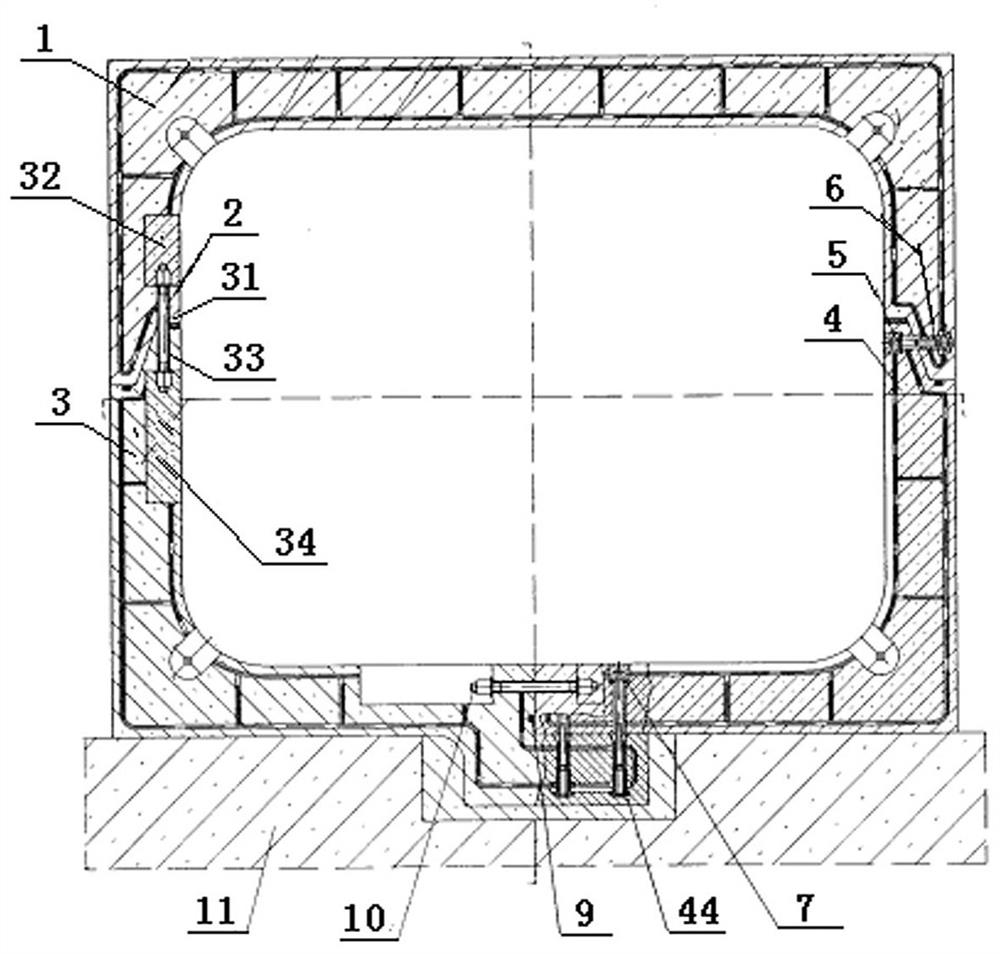

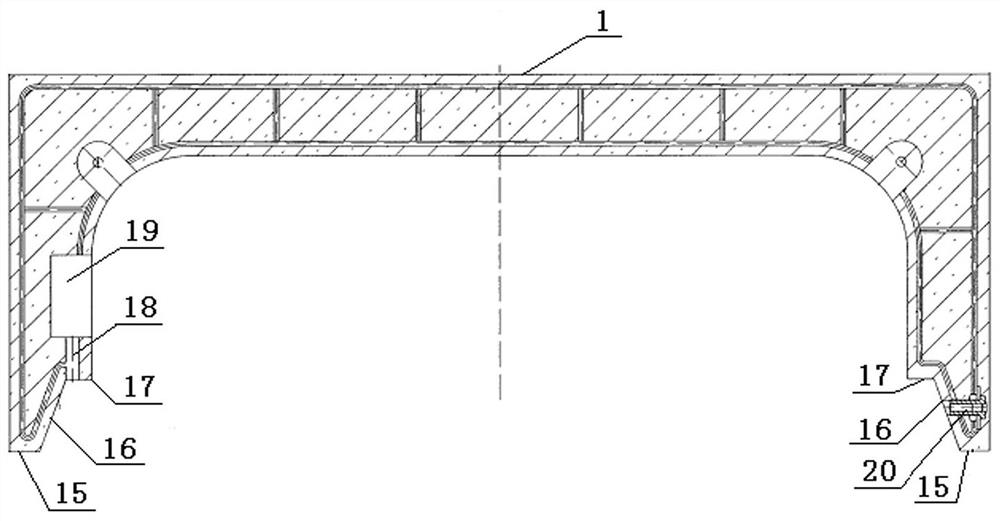

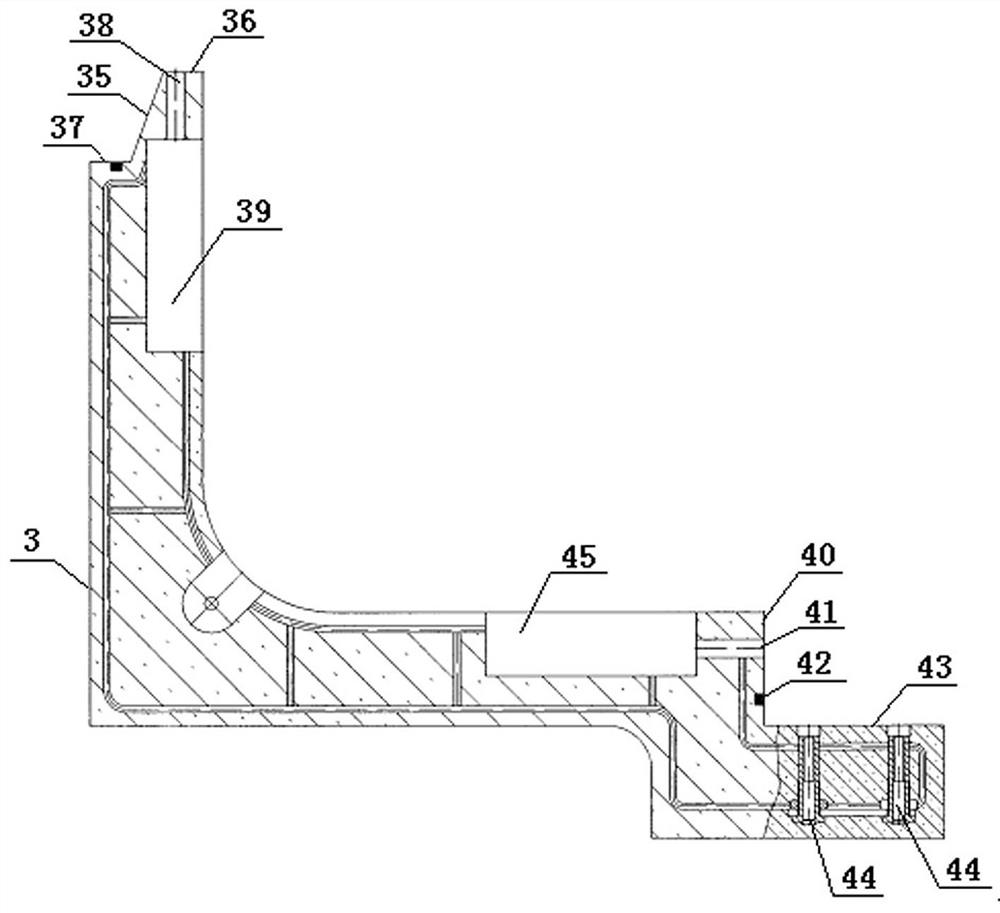

[0015] The two side walls of the upper U-shaped member 1 have symmetrical second and fourth lower end faces 15, first and second inner slopes 16 and first and third lower end faces 17, and the first and second lower end faces are located on the first inner slope respectively. , lower end, the 3rd and 4th lower end surfaces are located on the second inner slope and the lower end respectively, the first lower end surface 17 of the left side wall has a first vertical bolt hole 18 communicating with the first operating space 19, and the right side wall is pre-embedded with Horizontal nut 20, the left end surface 21 of the upper U-shaped member 1 is connected to the upper end of the left inclined surface 22, the lower end of the left inclined surface is connected to the left connecting seat 23, and the left connecting seat 23 has a horizontal bolt hole 24 to connect with the left operating space 25, and the upper U-shaped member 1. The right end surface 26 is connected to the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com