Water pump shaft coupling bearing

A technology for water pump shafts and bearings, which is applied in the field of water pump shafts and bearings, and can solve problems such as water seal leakage, bearing damage, and water pump failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

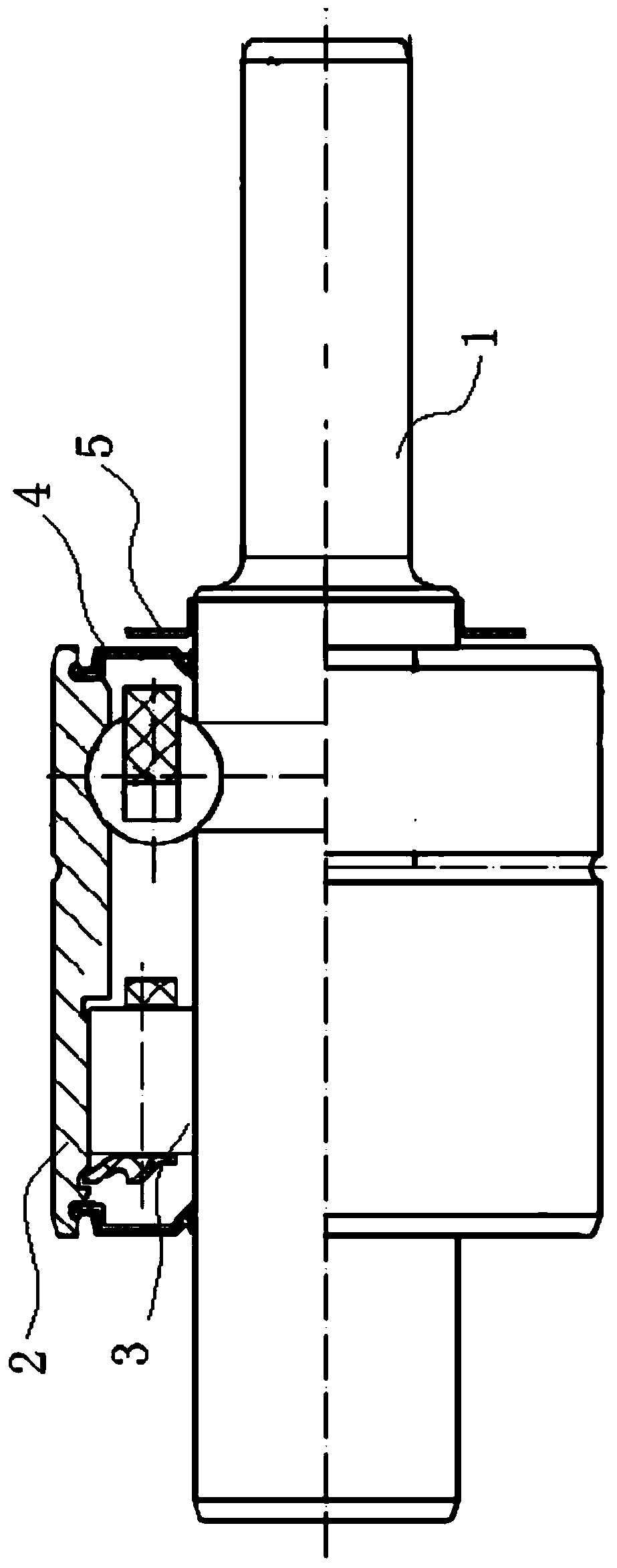

[0018] like figure 1 As shown, a water pump shaft-connected bearing includes a main shaft 1 and an outer ring 2, a roller 3 is arranged between the main shaft 1 and the outer ring 2, and the two ends of the outer ring 2 and the main shaft main shaft 1 A water seal 4 is arranged between them, and the end of the main shaft 1 adjacent to the inner chamber of the water pump is provided with a water-spinning ring 5 . The water is thrown out by the water ring, thus avoiding the damage of the bearing caused by water entering between the main shaft and the outer ring from the water seal.

Embodiment 2

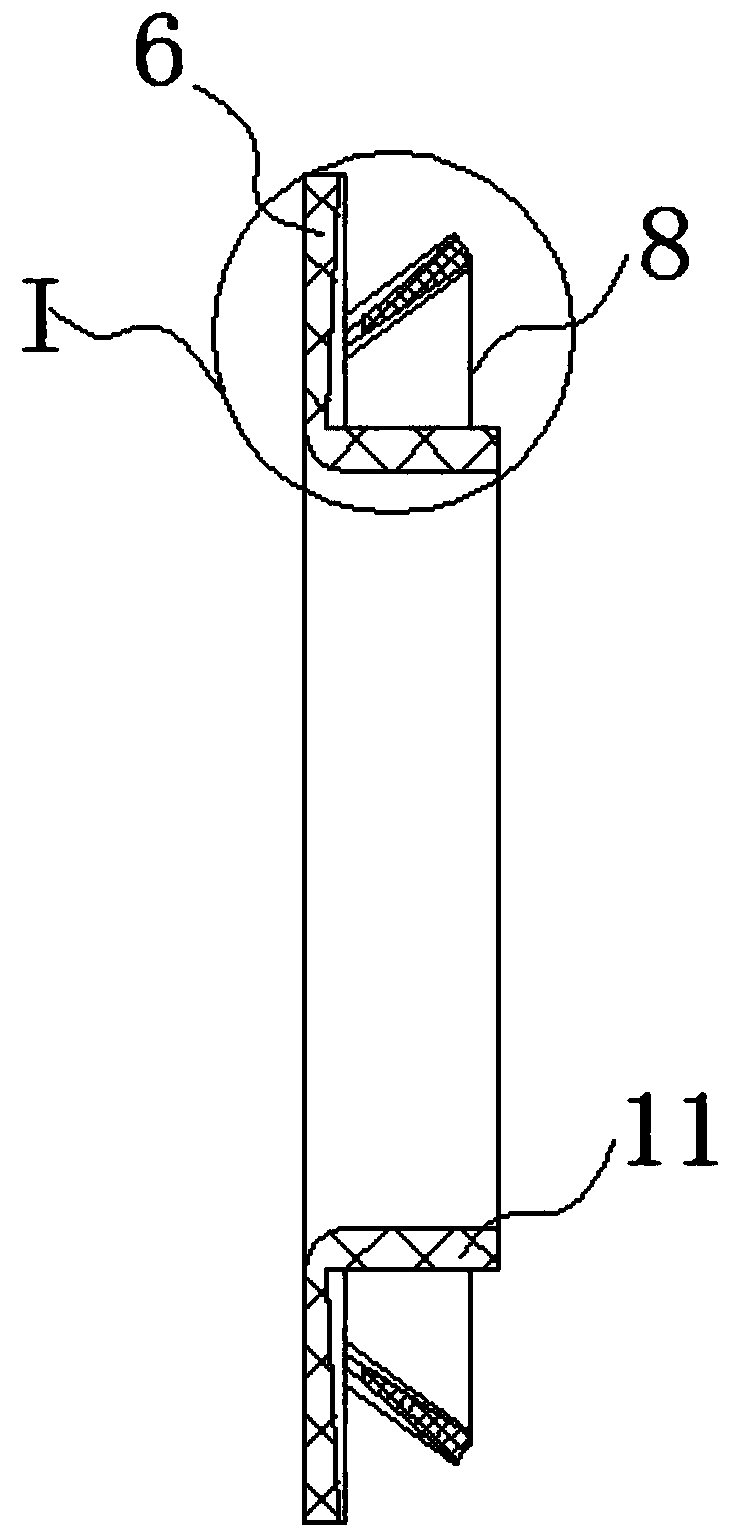

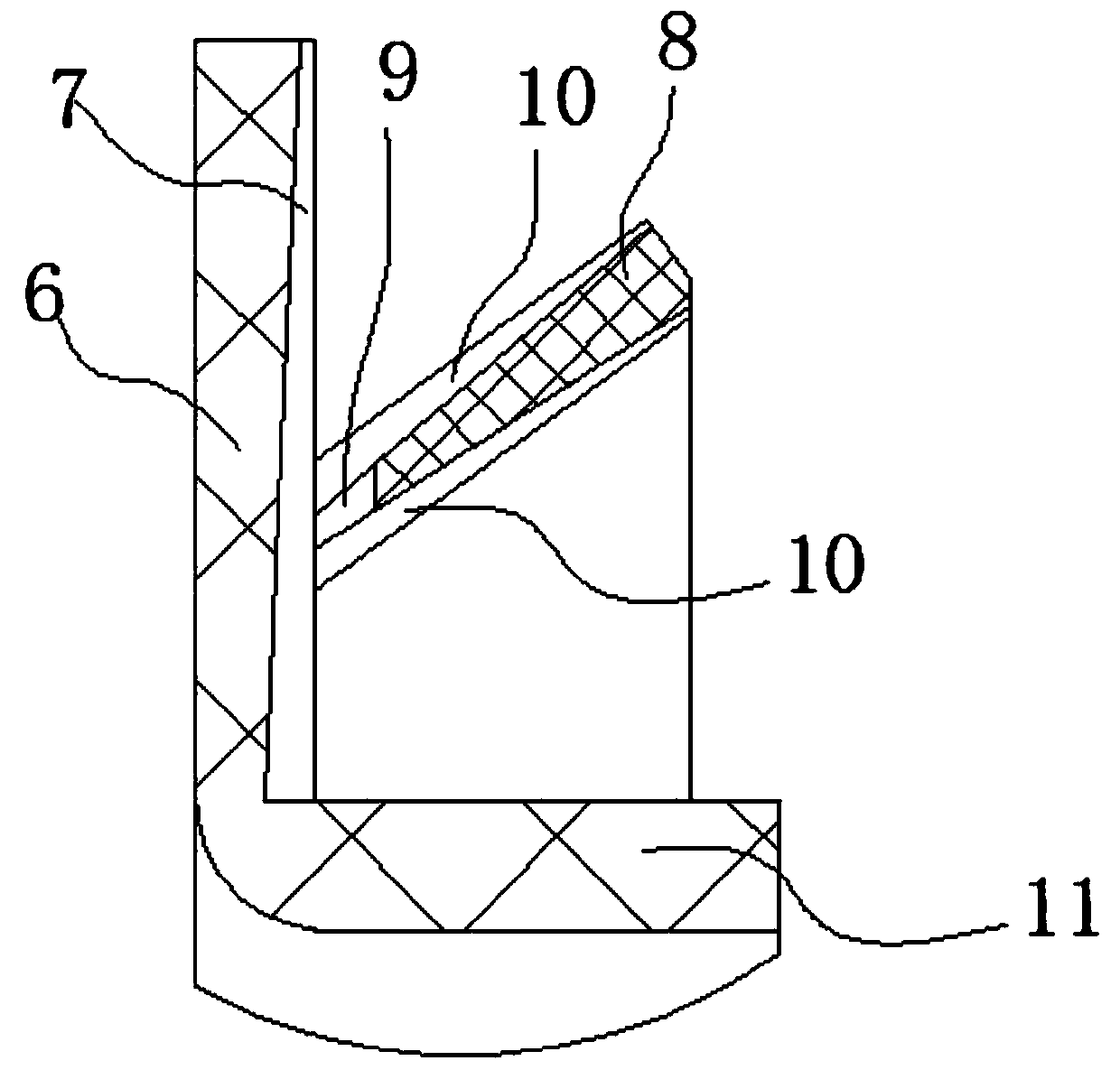

[0020] like figure 2 and image 3 As shown, the structure of Embodiment 2 is basically the same as that of Embodiment 1, the difference is that the water throwing ring 5 includes an annular body 6, and the inner hole of the annular body is connected with a sleeve that is sleeved outside the main shaft. A barrel 11, the outer surface of the annular body 6 is adjacent to the inner cavity of the water pump and is provided with a radial water groove 7 extending radially.

[0021] The depth of the end of the radial water groove 7 adjacent to the main shaft is greater than the depth of the end of the radial water groove 7 away from the main shaft. This makes it easier for water to be thrown from the radial gutters.

[0022] The annular body 6 is also provided with a conical water-spinning cylinder 8 positioned on the outer surface of the annular body 6, the small end of the conical-shaped water-spinning cylinder 8 is fixedly mounted on the annular body 6, and the conical water-sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com