Controllable-pitch propeller hydraulic system redundancy control valve unit

A hydraulic system and redundant control technology, which is applied to the safety of fluid pressure actuation systems, servo motor components, fluid pressure actuation devices, etc., can solve the problem that the crew cannot enter the cabin for maintenance, and achieve the effect of redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

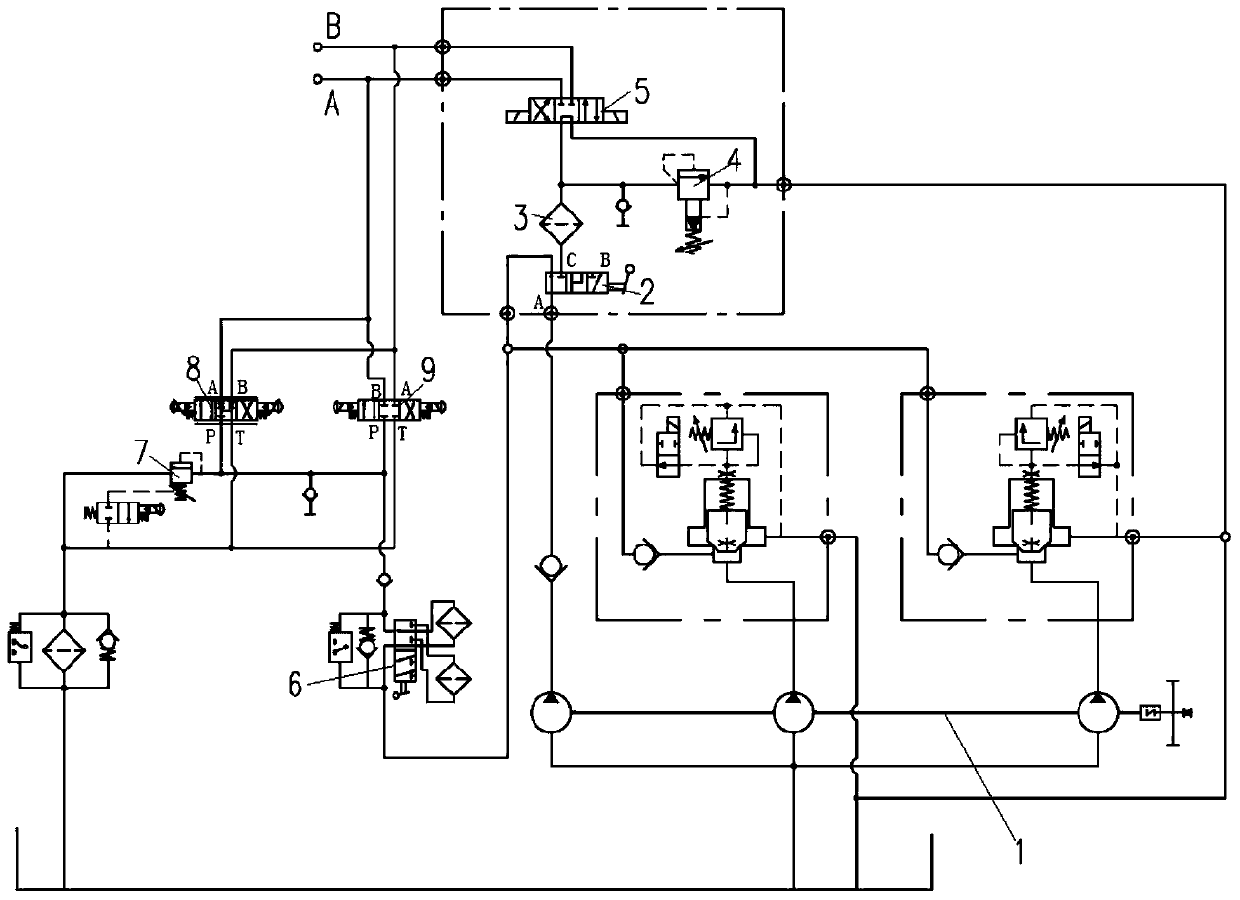

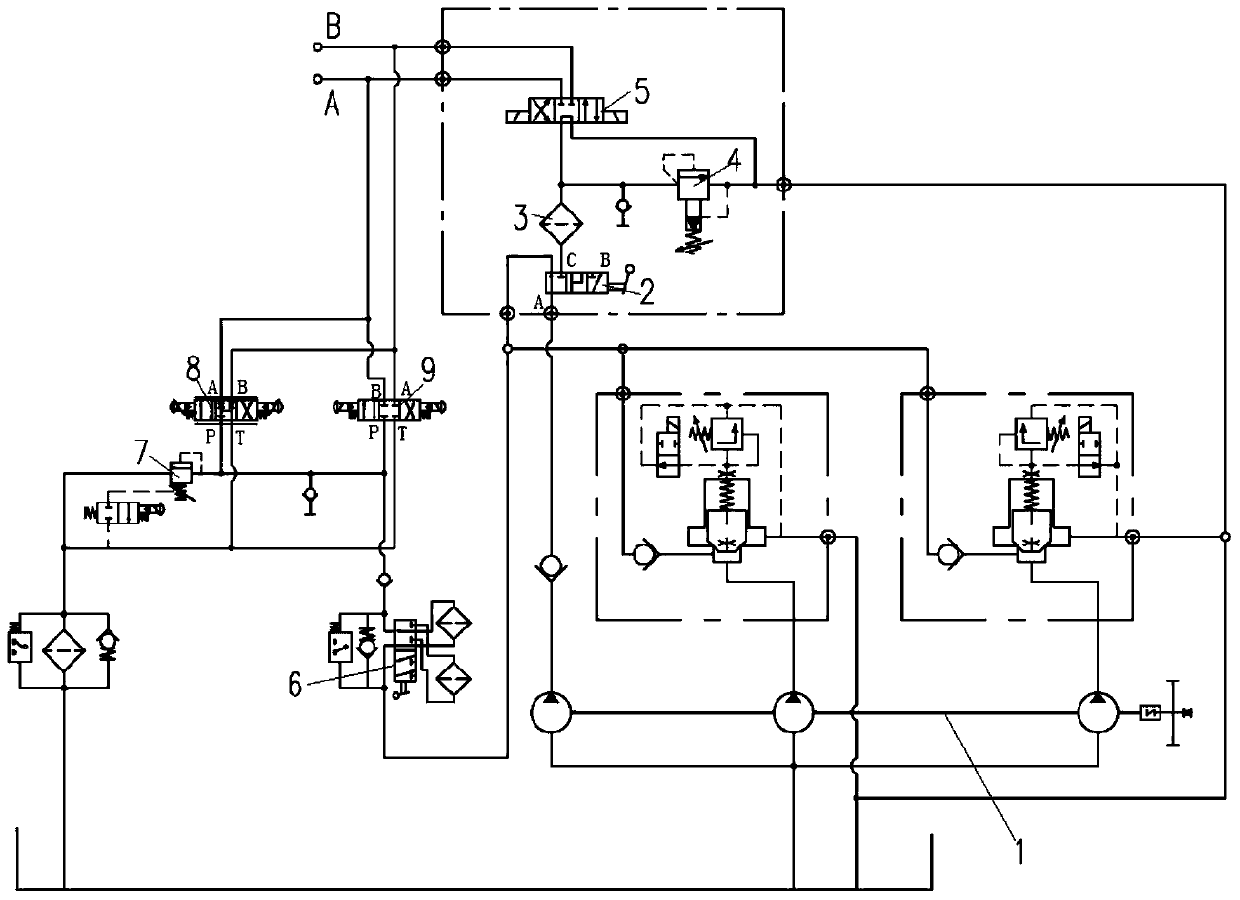

[0015] like figure 1 As shown, the redundant control valve group of the controllable pitch propeller hydraulic system of the present invention includes a triple pump group 1, a three-way ball valve 2, a high valve group filter 3, an electromagnetic overflow valve 4, an electro-hydraulic reversing valve 5, a double Connected filter 6, electromagnetic overflow valve 7, proportional valve 8, electro-hydraulic reversing valve 9.

[0016] The first pump, the second pump and the third pump in the triple pump group 1 are connected together through shafts. The first pump in the triple pump group 1 is connected to the high control valve group and the main control valve group respectively through the three-way ball valve 2, and the high control valve group and the main control valve group are respectively connected to the actuator cylinder of the control pitch propeller. When worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com