Box-type ceramic three-way valve with flow channel being conveniently switched on line

A three-way valve and box-type technology, applied in the field of pneumatic conveying system and box-type ceramic three-way valve, can solve the problems of troublesome operation of online switching flow channel, inability to realize online switching flow channel, stuck or stuck in the sealing position, etc. , to achieve the effect of guaranteeing service life, flexible adjustment and online switching, avoiding jamming or jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

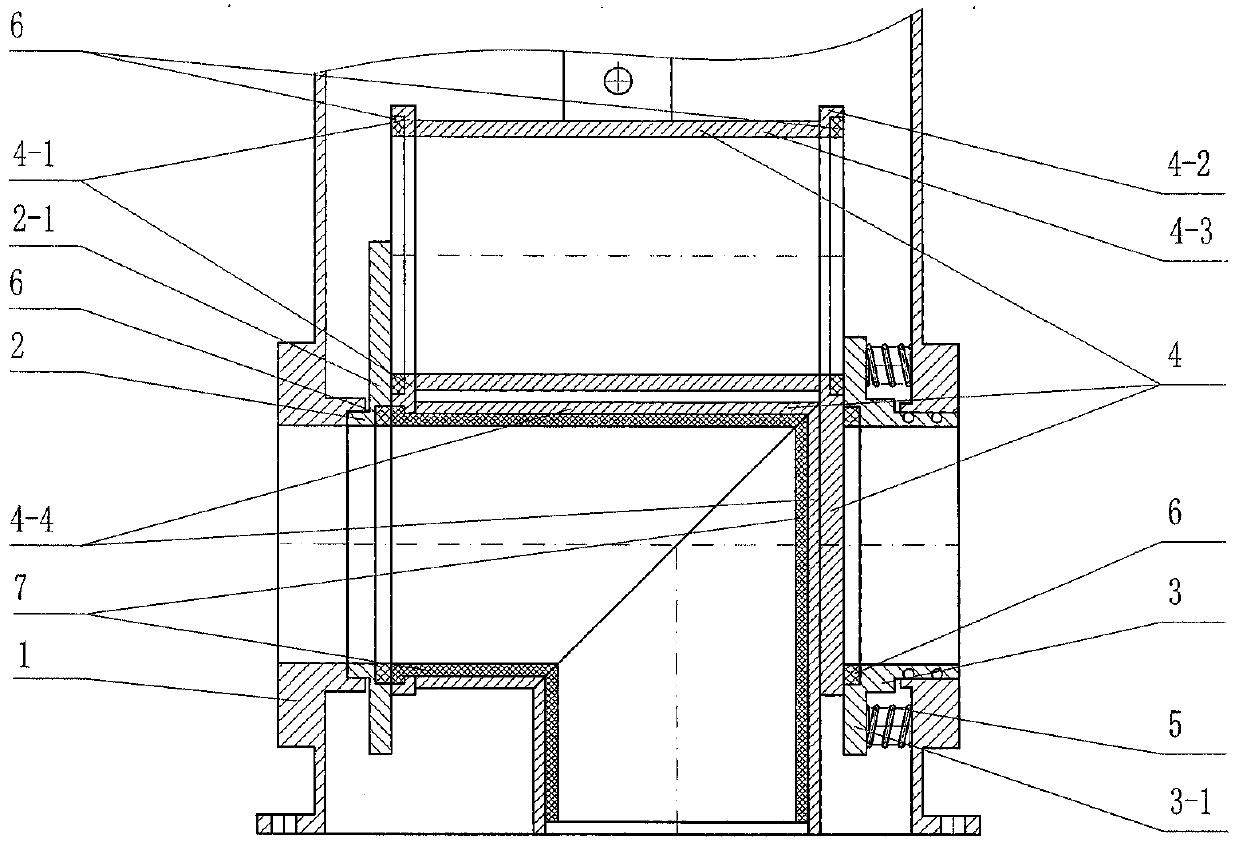

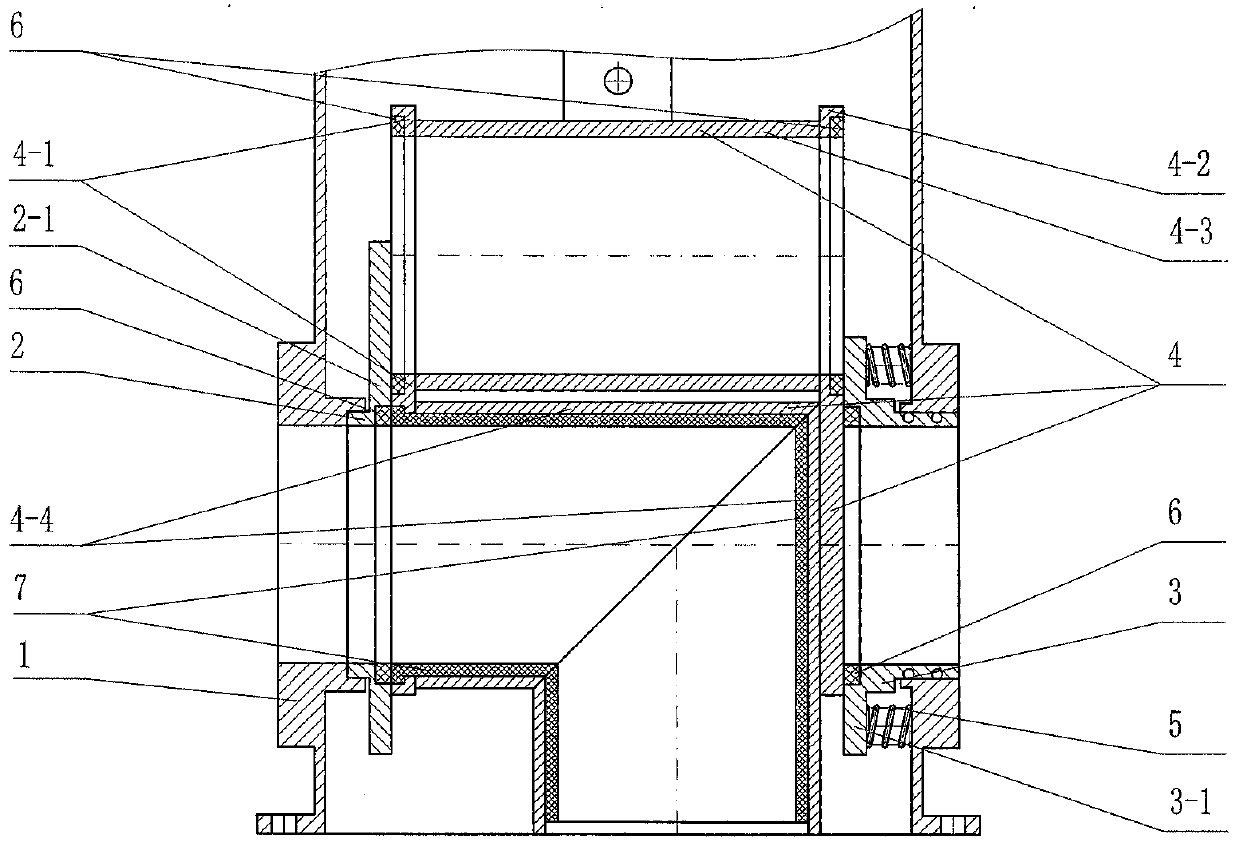

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, a box-type ceramic three-way valve of the present invention that facilitates online switching of flow channels includes a box-type valve body (1), which is embedded in the two proximal ends of the box-type valve body (1) flow channel cavity in a coaxial manner. 1. The fixed valve seat (2) and the elastic valve seat (3) in the form of a flange sleeve are stuck on the flange plate I (2-1) of the fixed valve seat (2) and the elastic valve seat (3). The movable spool (4) that can slide up and down between the blue plates II (3-1) (according to the switching needs of the material flow direction, the actuator connected to the movable spool (4) is controlled to drive the movable spool (4) along the The track consisting of the flange plate Ⅰ (2-1) of the fixed valve seat (2) and the flange plate Ⅱ (3-1) of the elastic valve seat (3) moves up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com