Fast and flexible three-dimensional inspection system for automatic processing of automobile sealing strip robot

A technology for automotive sealing strips and three-dimensional detection, which is applied in the direction of instruments, measuring devices, and optical devices, etc., can solve problems such as the inability to realize fast and flexible three-dimensional detection, achieve rich measurement information, simplify production processes, and save plant space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

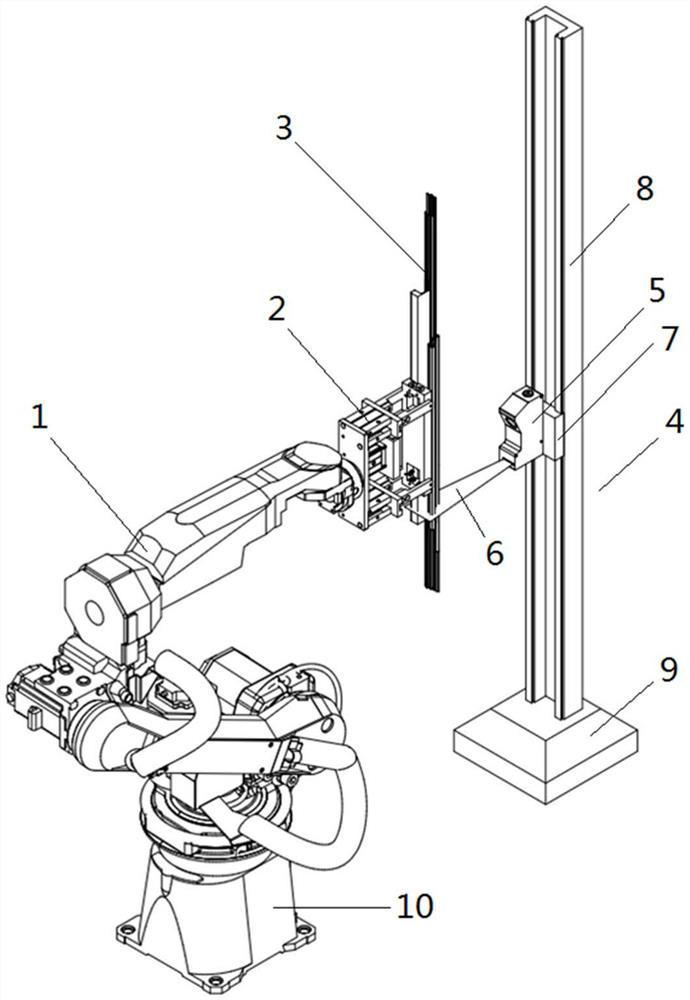

[0030] A fast and flexible three-dimensional detection system suitable for automatic processing of automotive sealing strip robots, its structure is as follows figure 1 As shown, it mainly includes a robot arm 1, a fixture 2, a guide rail slide 4, a laser profile sensor 5, a distance signal source, and a computer used in conjunction with it.

[0031] The robot arm 1 is the robot arm 1 used in the automatic processing of the automobile sealing strip robot arm, which is a multi-axis linkage structure and can freely rotate in the directions of X, Y, and Z axes. The manipulator base 10 is fixed on the ground and is relatively stationary with the guide rail slide table base 9 . A gripper 2 is fixed at the end of the robot arm 1 . Through the movement of the manipulator 1 , the measured workpiece 3 held by the clamp 2 is located in the scanning area 6 of the laser profile sensor, and the measured surface of the measured workpiece 3 faces the laser profile sensor 5 . The workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com