An asphalt ductility testing device and a method for making a sample

A technology for asphalt and test molds, which is applied in the field of preparation devices for asphalt ductility test molds. It can solve the problems of affecting the test accuracy, easy hollowing, and troublesome disassembly and assembly, so as to improve test accuracy, ensure compactness, and facilitate disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

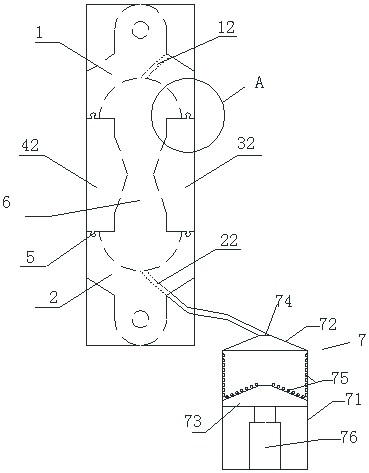

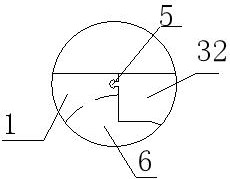

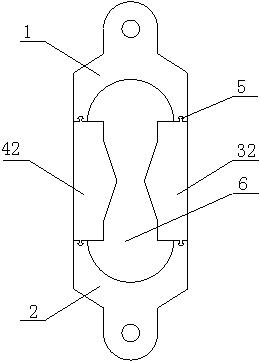

[0040] Such as Figure 1-5 , shown in 7, a kind of asphalt ductility testing device, comprising first end mold 1, second end mold 2, first side mold 32, second side mold 42, bottom plate 41, top plate 31, described first end The mold 1, the second end mold 2, the first side mold 32, the second side mold 42, the bottom plate 41, and the top plate 31 form an asphalt cavity 6. The first side mold 32 and the top plate 31 are integrally formed. The two side molds 42 are integrally formed with the bottom plate 41, thus forming the top plate 31 with side molds and the bottom plate 41 with side molds, which can accurately control the relative positions of the side molds, the top plate 31 and the bottom plate 41, and improve the test accuracy.

[0041] Both the first side mold 32 and the first end mold 1 and the second end mold 2 are clamped and assembled by the locking device 5, and the second side mold 42 is connected to the first end mold 1 and the second end mold 2 They are also cla...

Embodiment 2

[0050] A method for making an asphalt ductility test sample, comprising the steps of:

[0051] (1) Provide the asphalt ductility mold testing device of Example 1, and apply the release agent evenly on the positions of the first side mold 32, the second side mold 42, the bottom plate 41, and the top plate 31 corresponding to the mold cavity 6;

[0052] (2) Place the bottom plate 41 with the second side form 42 horizontally on the test bench with the second side form 42 facing upwards, and the first end form 1 connects with the second side form 42 through the corresponding female groove 51 on it. The male buckle 52 on the end face of the upper side is slidably inserted and assembled from the top end of the second side mold 42 to the bottom end, and the second end mold 2 is connected to the other end surface of the second side mold 42 through the corresponding female groove 51 on it. The male buckle 52 is slid and inserted from the top end to the bottom end of the second side mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com