A kind of heterogeneous catalyst for preparing isophorone and its preparation and application

A heterogeneous catalyst and isophorone technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, carbon-based compound preparation, etc., can solve the problems of low conversion rate and decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

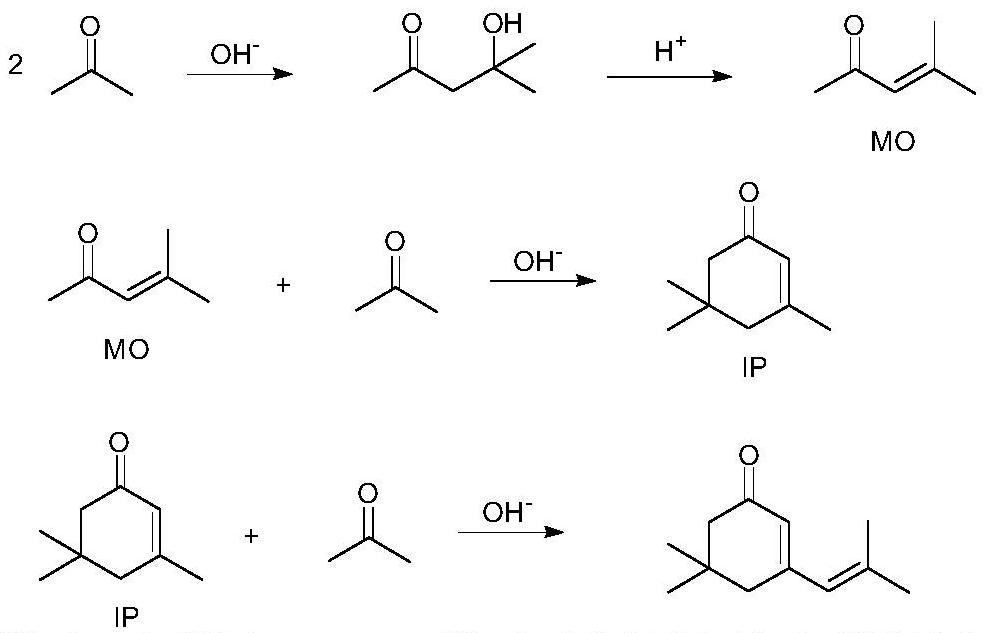

Method used

Image

Examples

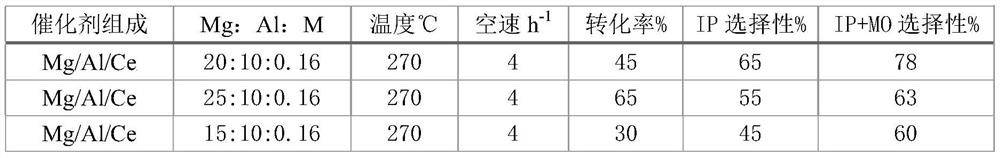

Embodiment 1

[0038] The nitrate is configured as a mixed salt solution according to the molar ratio Mg:Al:Ce=20:10:0.16, weigh 25g of magnesium nitrate hexahydrate, 18.29g of aluminum nitrate nonahydrate, and 0.43g of ammonium cerium nitrate, and dissolve them in 100ml of distilled water , add 1 gram of template agent hexamethylenetetramine, 1 gram of amantadine; prepare lye at the same time: mix 9.35 grams of NaOH and 6.36 grams of NaOH2 CO 3 Dissolve in 50ml of water to obtain a precipitate. At 80°C, drop the precipitating agent into the mixed salt solution, the pH of the mixed solution is 8-9, continue stirring for 5 hours and then let stand for 12 hours. The mixed solution was filtered, washed three times with water, the filter cake was dried at 120°C for 12h, and baked at 550°C for 5h. The above catalyst was used for the reaction of acetone condensation to prepare isophorone, using a fixed-bed reactor filled with 3 grams of catalyst. Under normal pressure, pump acetone into the syst...

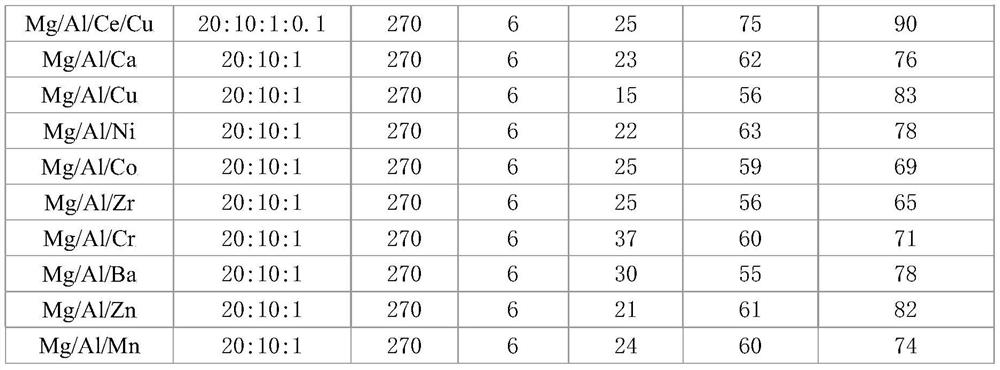

Embodiment 2

[0040] Nitrate is configured mixed salt solution according to molar ratio Mg:Al:Ce:Cu=20:10:0.16:0.1, weighs 25g magnesium nitrate hexahydrate, 18.29g aluminum nitrate nonahydrate, 0.43g ammonium cerium nitrate, 0.2 gram nitric acid Copper, dissolve it in 100ml distilled water, add 1 gram of template agent hexamethylenetetramine, 1 gram of octadecyltrimethylammonium chloride; prepare lye at the same time: mix 9.35 grams of NaOH and 6.36 grams of NaOH 2 CO 3 Dissolve in 50ml of water to obtain a precipitate. At 80°C, drop the precipitating agent into the mixed salt solution, the pH of the mixed solution is 8-9, continue stirring for 5 hours and then let stand for 12 hours. The mixed solution was filtered, washed three times with water, the filter cake was dried at 120°C for 12h, and calcined at 600°C for 5h. The above catalyst was used for the reaction of acetone condensation to prepare isophorone, using a fixed-bed reactor filled with 3 grams of catalyst. Under normal press...

Embodiment 3

[0042] Nitrate is configured mixed salt solution according to molar ratio Mg:Al:Ce:Cu=20:10:1:0.1, weighs 25g magnesium nitrate hexahydrate, 18.29g aluminum nitrate nonahydrate, 2.67g ammonium cerium nitrate, 0.2 gram nitric acid Dissolve copper in 100ml of distilled water, add 1 gram of template agent hexamethylenetetramine, 1 gram of tetraethylammonium hydroxide; prepare lye at the same time: mix 8.88 grams of NaOH and 6.04 grams of NaOH 2 CO 3 Dissolve in 50ml of water to obtain a precipitate. At 80°C, drop the precipitating agent into the mixed salt solution, the pH of the mixed solution is 7-8, continue stirring for 5 hours and then let it stand for 12 hours. The mixed solution was filtered, washed three times with water, the filter cake was dried at 120°C for 12h, and then calcined at 650°C for 5h. The above catalyst was used for the reaction of acetone condensation to prepare isophorone, using a fixed-bed reactor filled with 3 grams of catalyst. Under normal pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com