A kind of ABS composition and preparation method thereof

A technology of composition and ABS resin, which is applied in the field of polymer materials, can solve problems such as difficult control of process parameters, increase of material cost, impact on impact performance, etc., to improve laser marking performance, maintain impact strength, and good impact strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention further illustrates the invention, but the present invention is not limited by the following examples.

[0043] The raw materials used in the present invention are derived from commercially available products, and some raw materials are as follows:

[0044] Glycene Polymer A: Styrene - Methyl Acrylic Acid Glycerides;

[0045] Glyceride polymer B: methacrylate polymer;

[0046] ABS: Styrene-butadiene-acrylonitrile-methyl methacrylate copolymer;

[0047] Carbon black: black toner;

[0048] Conductive carbon black: black toner;

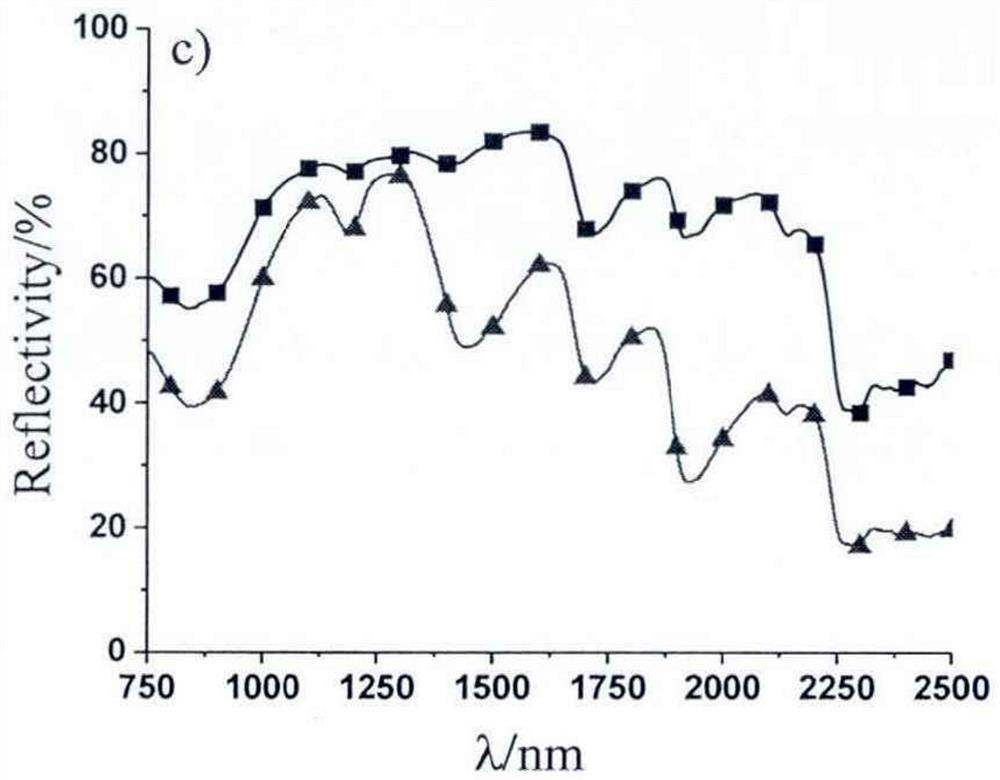

[0049] Near infrared reflection pigment A: Cr 2 O 3 : Fe 2 O 3 , Iron-chromium series metal oxide;

[0050] Near infrared reflection pigment B: Cuo: Fe 2 O 3 , Iron-copper series metal oxide;

[0051] EXAMPLES: Preparation of ABS Composition: ABS resin, glycid ester polymer, near infrared reflective pigment, auxiliary powder is added to the high-speed mixing machine in accordance with the ratio weighing. The extruder extruder is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com