Modified PP (polypropylene) material easy to sweat weld, high in transparency and easy to laser mark as well as preparation method and application of modified PP material easy to sweat weld, high in transparency and easy to laser mark

A hot-melt welding and laser marking technology, which is applied in the field of modified plastics, can solve the problems of easy hot-melt welding and the inability of modified PP materials to meet high transparency at the same time, so as to improve compatibility and laser marking clarity , Improve the effect of laser marking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

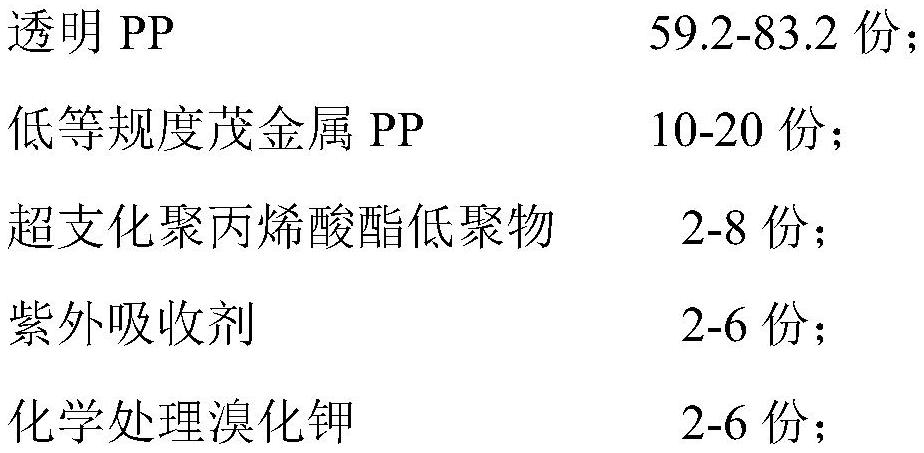

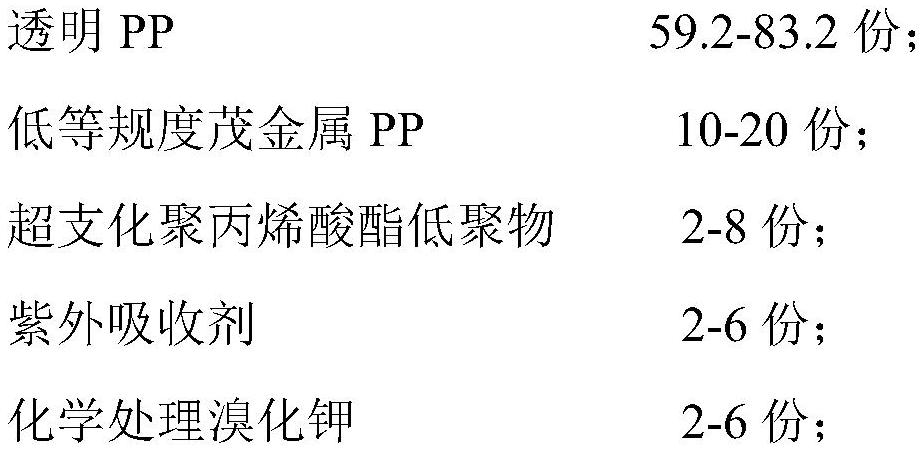

[0064] Preparation method of modified PP material:

[0065] Mix the components according to the formula in Table 1 or Table 2, and then feed them from the main feeding port of the twin-screw extruder, melt, extrude, and granulate in the extruder to obtain, and the extruder melts and extrudes The processing conditions are as follows: the temperature in the first zone is 190-200°C, the temperature in the second zone is 190-200°C, the temperature in the third zone is 200-210°C, the temperature in the fourth zone is 200-210°C, the temperature in the fifth zone is 210-220°C, and the temperature in the sixth zone is 210°C. -220°C, the temperature in the seventh zone is 220-230°C, the temperature in the eighth zone is 220-230°C, the temperature in the ninth zone is 220-230°C, and the speed of the host is 250-350 rpm.

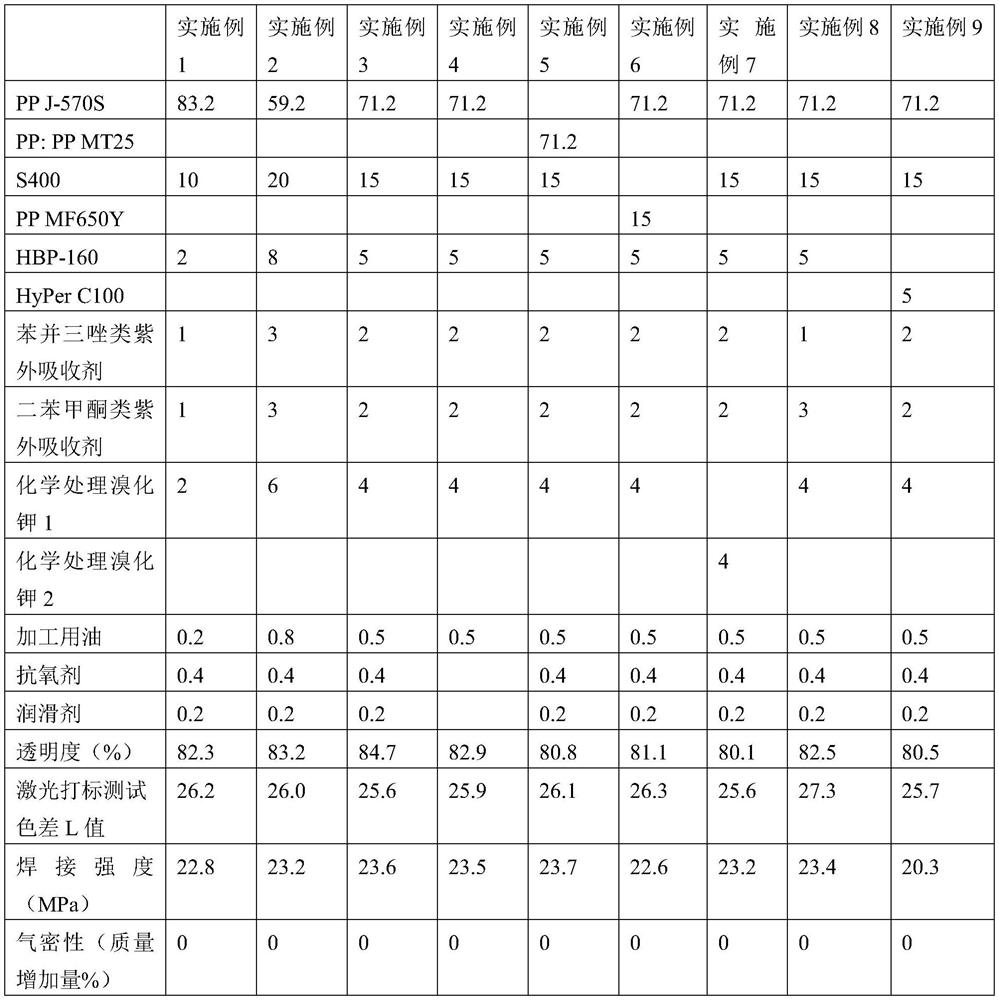

[0066] Performance Testing:

[0067] (1) Transparency: Tested according to the standard ASTM D1003-2013 method.

[0068] (2) The laser marking test method is as foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com