An electrode structure for in situ observation of lithium ion diffusion process

An electrode structure and lithium ion technology, applied in the field of electrochemistry, can solve the problems of inconvenient diffusion research, complex constraints, and reflect the diffusion process of lithium ions, so as to facilitate in-situ observation, avoid constraints, and increase diffusion distance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The design process of the present invention will be further described below through specific examples. It should be noted that this example is illustrative rather than limiting, and does not limit the protection scope of the present invention.

[0024] The structure design process for in situ measurement of the electrode diffusion process is divided into the following four parts:

[0025] (1) Preparation of electrode structural parts

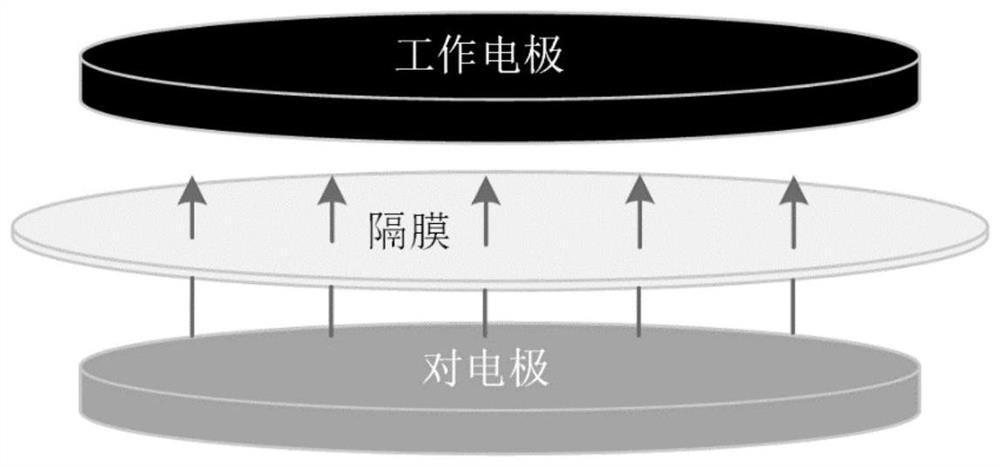

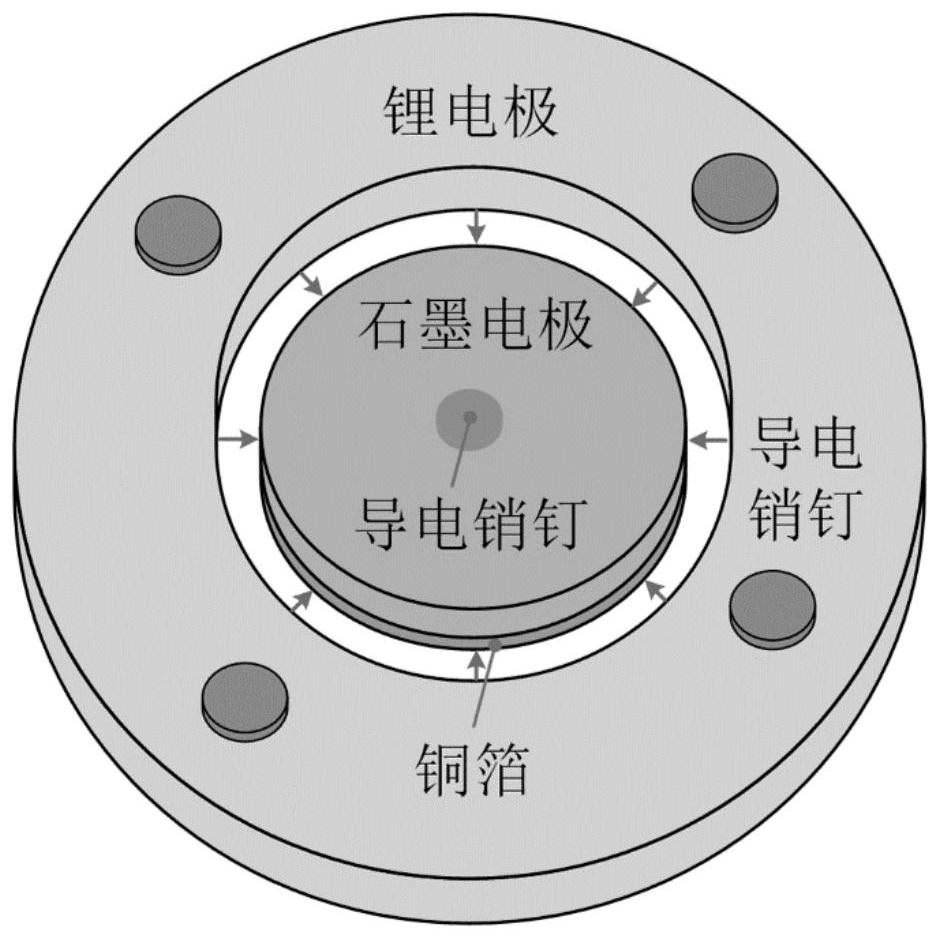

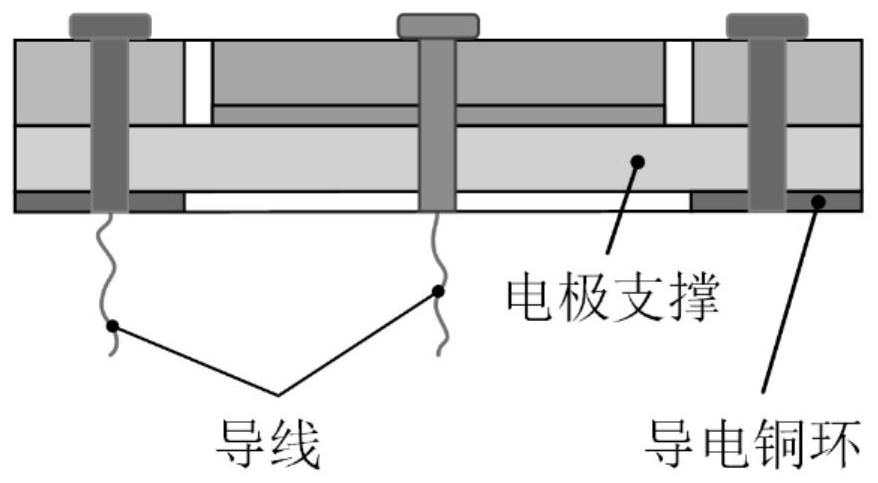

[0026] The electrode structure components used in this embodiment mainly include working electrode (graphite electrode), counter electrode (lithium electrode), conductive metal pin (copper material), wire, electrode support body, conductive copper ring, etc., such as figure 2 , image 3 shown. The working electrode specimen is a flake electrode made by uniformly coating the graphite composite material on the copper foil current collector. After preparation, the circular die knife is used to cut the flake graphite electrode. The shape o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com