Equipment and method for recycling gold by recycling electronic wastes

An electronic waste and recycling technology, applied in the improvement of process efficiency, grain processing and other directions, can solve problems such as affecting the efficiency of gold refund processing, and achieve the effect of environmentally friendly gold recycling process and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

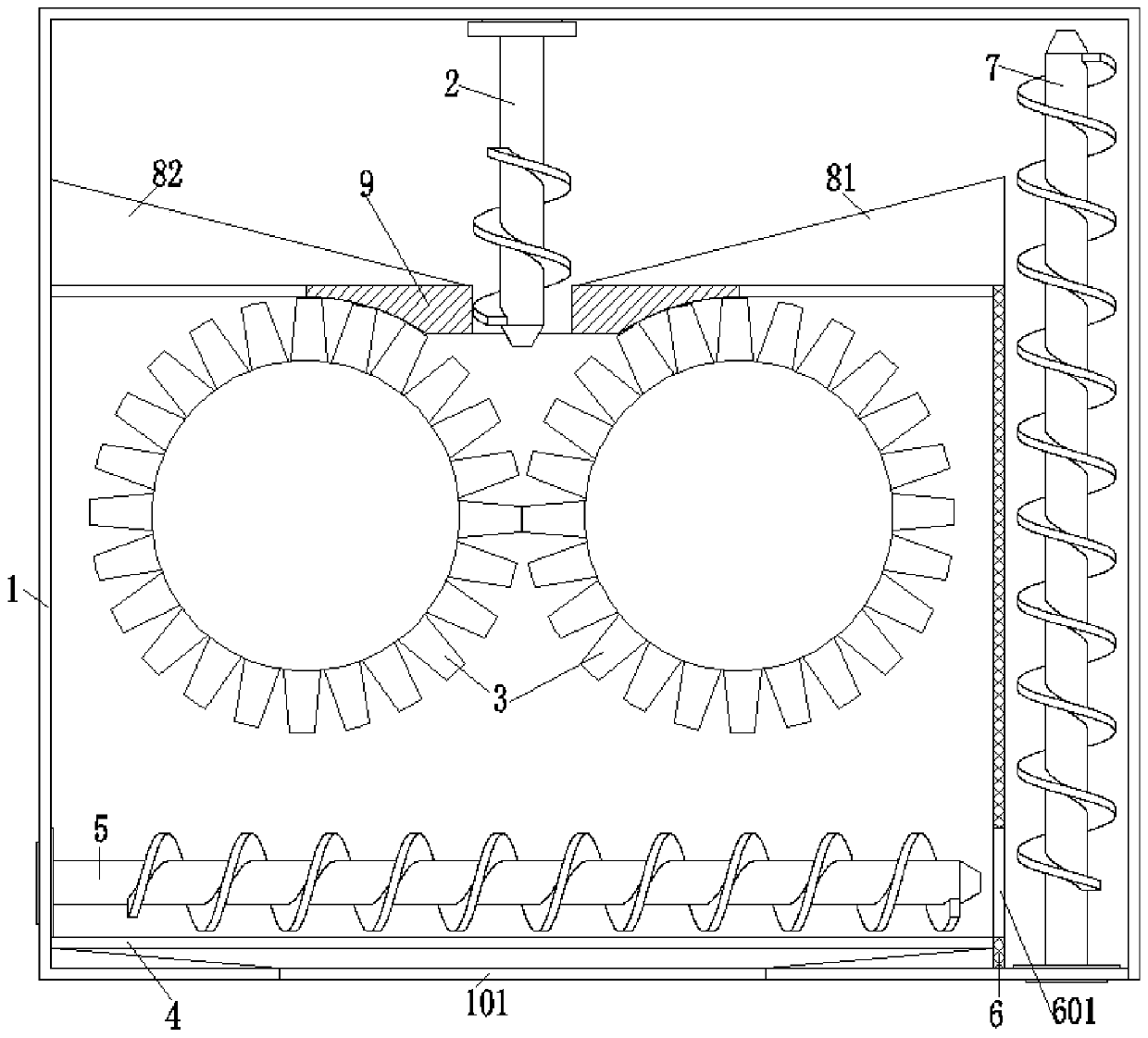

Image

Examples

Embodiment 1

[0044]The method for recovering gold by using the above-mentioned equipment for recycling gold from electronic wastes comprises the following steps:

[0045] (1) Put the electronic waste into the crushing mechanism, and the crushed electronic waste is obtained after crushing; the particle size of the crushed electronic waste is controlled within a certain range (determined according to the aperture of the screening plate).

[0046] (2) Add the pulverized electronic waste of step (1) into the stirring mechanism, under the agitation of the stirring paddle of the stirring mechanism, add the prepared gold removal solution, the gold removal solution can dissolve the gold of the pulverized electronic waste, and filter to remove Gold solution (containing gold ions); the pulverized electronic waste whose particle size is controlled within a certain range is degolded by the degolding solution, and the effect of the degolding treatment is better and the efficiency is higher. Wherein, th...

Embodiment 2

[0052] The method for recovering gold by using the above-mentioned equipment for recycling gold from electronic wastes comprises the following steps:

[0053] (1) Put the electronic waste into the crushing mechanism, and the crushed electronic waste is obtained after crushing; the particle size of the crushed electronic waste is controlled within a certain range (determined according to the aperture of the screening plate).

[0054] (2) Add the pulverized electronic waste of step (1) into the stirring mechanism, under the agitation of the stirring paddle of the stirring mechanism, add the prepared gold removal solution, the gold removal solution can dissolve the gold of the pulverized electronic waste, and filter to remove Gold solution (containing gold ions); the pulverized electronic waste whose particle size is controlled within a certain range is degolded by the degolding solution, and the effect of the degolding treatment is better and the efficiency is higher. Wherein, t...

Embodiment 3

[0059] The method for recovering gold by using the above-mentioned equipment for recycling gold from electronic wastes comprises the following steps:

[0060] (1) Put the electronic waste into the crushing mechanism, and the crushed electronic waste is obtained after crushing; the particle size of the crushed electronic waste is controlled within a certain range (determined according to the aperture of the screening plate).

[0061] (2) Add the pulverized electronic waste of step (1) into the stirring mechanism, under the agitation of the stirring paddle of the stirring mechanism, add the prepared gold removal solution, the gold removal solution can dissolve the gold of the pulverized electronic waste, and filter to remove Gold solution (containing gold ions); the pulverized electronic waste whose particle size is controlled within a certain range is degolded by the degolding solution, and the effect of the degolding treatment is better and the efficiency is higher. Wherein, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com