Two-stage type solid waste crushing mechanism

A technology of solid waste and pulverizing mechanism, which is applied in the direction of grain processing, etc., can solve the problems of low cost and large particle size, and achieve the effects of low cost, low cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

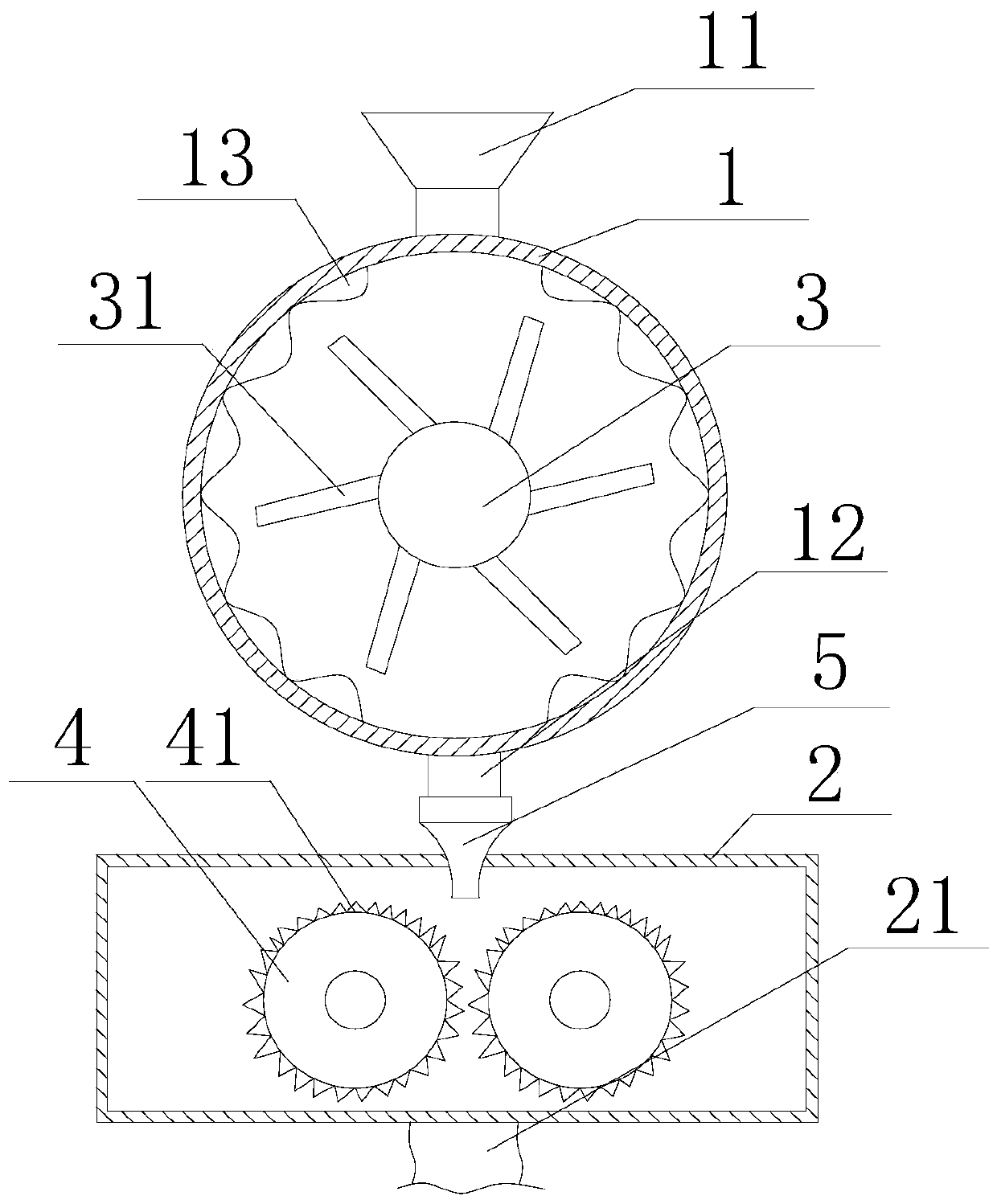

[0027] like figure 1 As shown, the two-stage solid waste crushing mechanism includes a primary crushing cylinder 1 and a secondary crushing cylinder 2, the primary crushing cylinder 1 is arranged above the secondary crushing cylinder 2, the upper end of the primary crushing cylinder 1 and the The lower end is respectively provided with a material inlet 11 and a discharge port 12, and the first-stage crushing cylinder 1 is provided with a rotating shaft 3, and the rotating shaft 3 is provided with a cutter 31, and the second-stage crushing cylinder 2 is provided with two The pressure rollers 4 that cooperate with each other, the bottom of the secondary crushing cylinder 2 is provided with a discharge port 21, and the top of the secondary crushing cylinder 2 is provided with an opening below the discharge port 12, and on the discharge port 12 A material guide cylinder 5 is provided, and the material guide cylinder 5 is arranged above the gap between the two pressure rollers 4 th...

Embodiment 2

[0029] like figure 1 As shown, the present embodiment is based on embodiment 1, the inner wall of the primary pulverizing cylinder 1 is provided with several wavy blades 13; The outer wall is provided with a sawtooth structure 41; both sides of the outlet end of the guide cylinder 5 are extruded inward to form a flat outlet, and the length direction of the flat outlet is consistent with the axial direction of the pressure roller 4; the primary crushing cylinder 1 is Cylindrical structure, the secondary crushing cylinder 2 is a rectangular frame structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com