3D printing sand mould

A 3D printing and sand molding technology, which is applied in the field of 3D printing sand molding, can solve the problems of unable to print large sand molds as a whole, and the parting surface running out of fire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

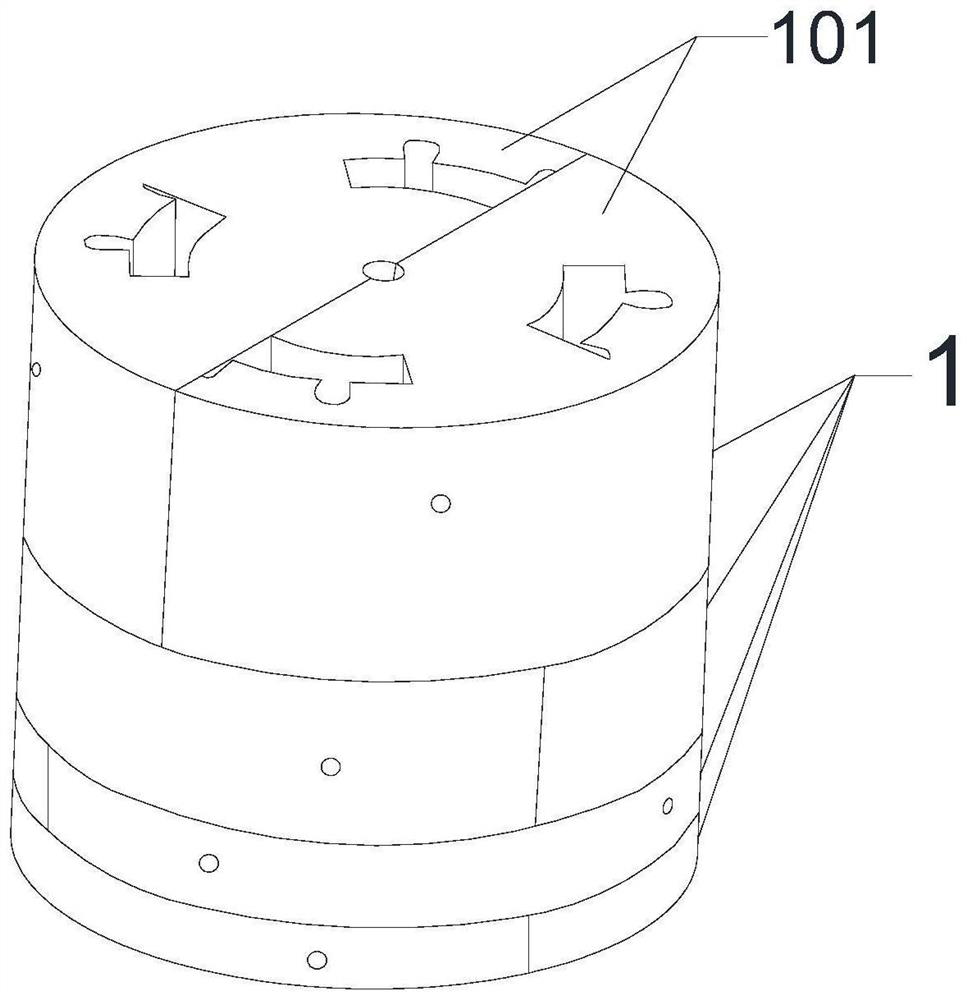

[0045] This embodiment provides a 3D printing sand mold, which is cylindrical as a whole, such as figure 1As shown, it includes four layers of transverse sand blocks 1, and the four layers of transverse sand blocks 1 are stacked up and down in sequence; wherein, the contact surface between the upper and lower adjacent layers of transverse sand blocks 1 is the transverse parting surface. Each horizontal sand mold block 1 includes two vertical sand mold blocks 101, and the contact surface between two adjacent vertical sand mold blocks 101 is a longitudinal parting surface, and the longitudinal parting surface and the transverse parting surface are perpendicular to each other. . And the longitudinal parting surface passes through the geometric center of the transverse sand mold block 1; the longitudinal parting surfaces on two adjacent layers of transverse sand mold blocks 1 are mutually misaligned. In the circumferential direction, the angle at which the vertical parting surfac...

Embodiment 3

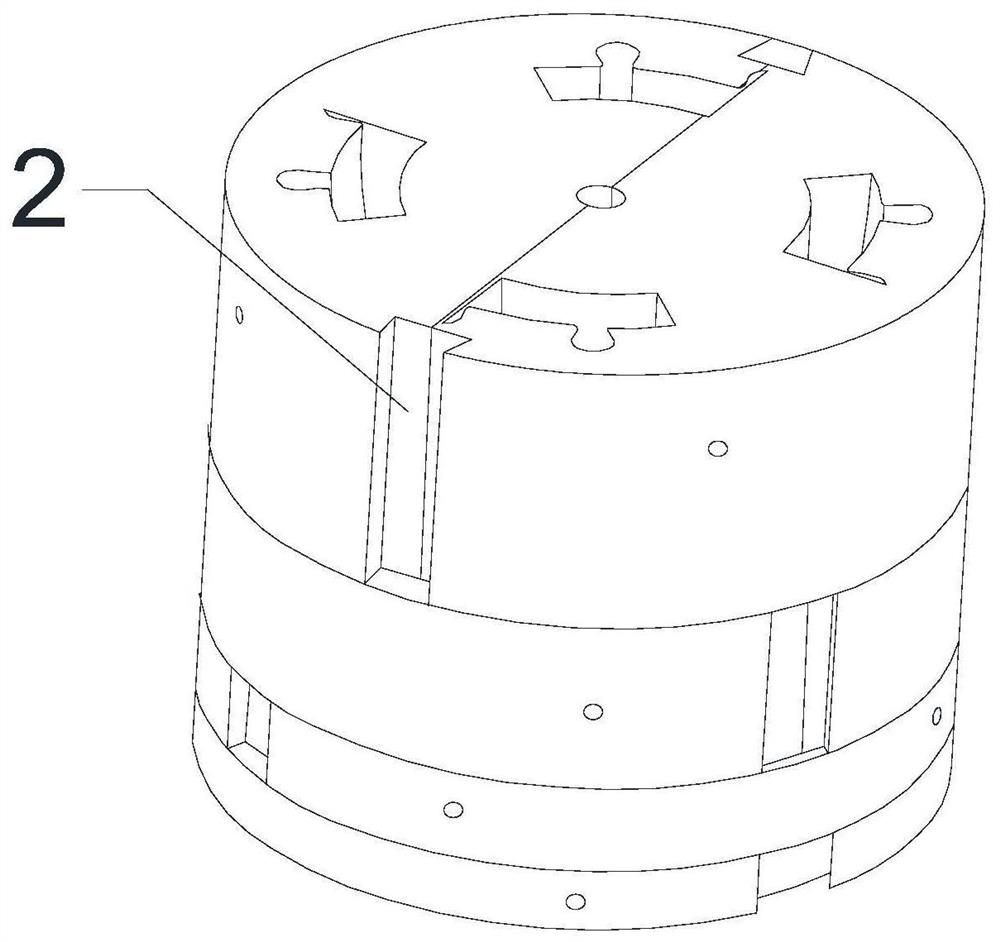

[0047] Further improvement on the basis of Example 2, a reserved groove 2 is provided at the outer slit of the longitudinal parting surface, and the outer boundary of the longitudinal parting surface is located at the bottom of the reserved groove 2; after the box is closed, The reserved groove 2 is used for filling clay sand or resin sand. The notch width of the reserved groove 2 is smaller than the width of the groove. In this embodiment, preferably, the reserved groove 2 has an isosceles trapezoidal structure on the cross section in the width direction of the reserved groove 2 .

Embodiment 4

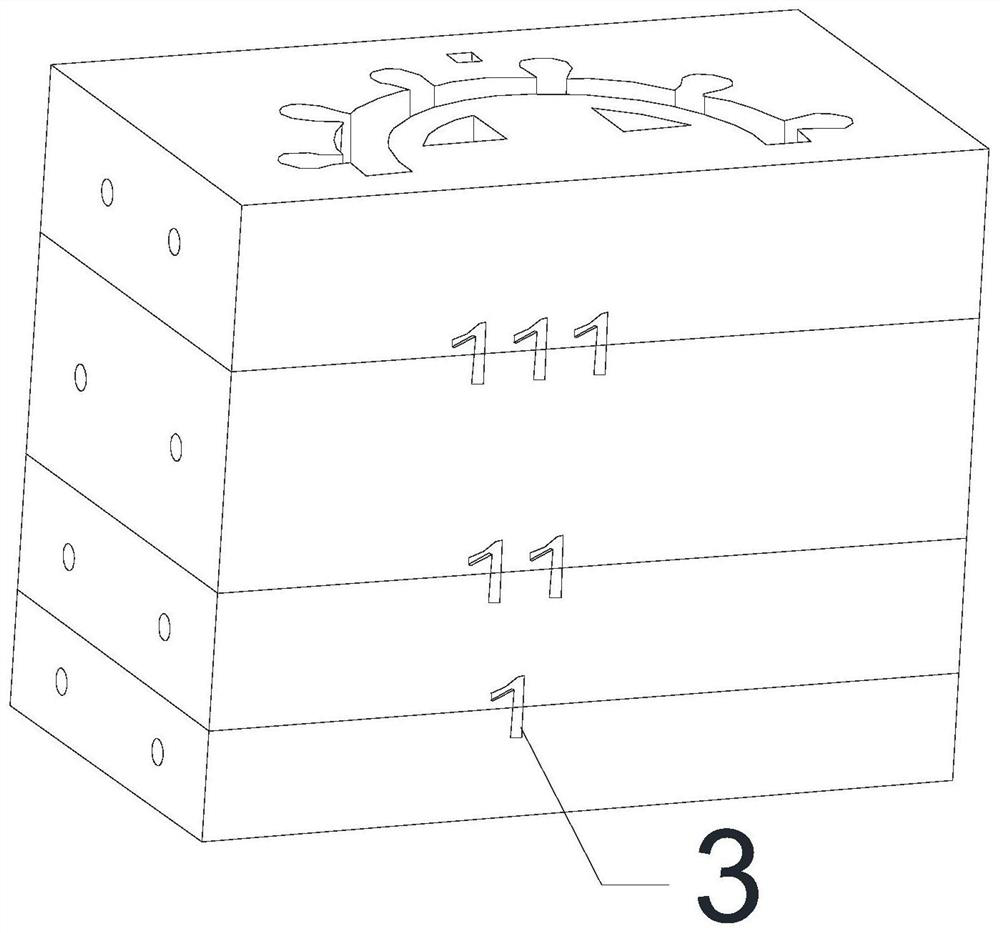

[0049] Further improvement on the basis of Example 3, positioning pins and positioning holes are respectively provided on the parting surfaces of the upper and lower adjacent horizontal sand blocks 1, and the positioning pins on the parting surface of one transverse sand block 1 are embedded in the adjacent Fit in the positioning hole on the parting surface of the transverse parting block 1. The circumferential gap between the positioning pin and the positioning hole is 1 mm, and the axial gap is 1 mm. Positioning holes or positioning pins are arranged on the transverse sand molding blocks 1 of the same layer, that is, the positioning types provided on the transverse sand molding blocks 1 of the same layer are the same.

[0050] Further preferably, the positioning number 3 is set on the side wall of the lateral sand molding block 1 of the adjacent layer, and the positioning number 3 runs through the upper and lower adjacent layers of the lateral sand molding blocks 1, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com