Corrosive foil cleaning device

A cleaning device and a technology for corroding foil, which is applied in the field of corroding foil processing, can solve the problems of no brushing structure, insufficient cleaning effect, long cleaning time, etc., and achieve the effect of ensuring and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

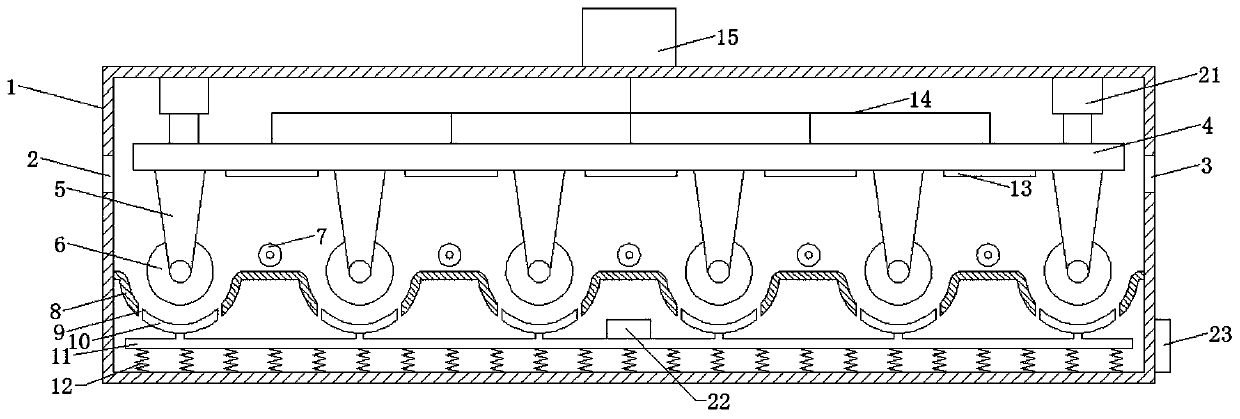

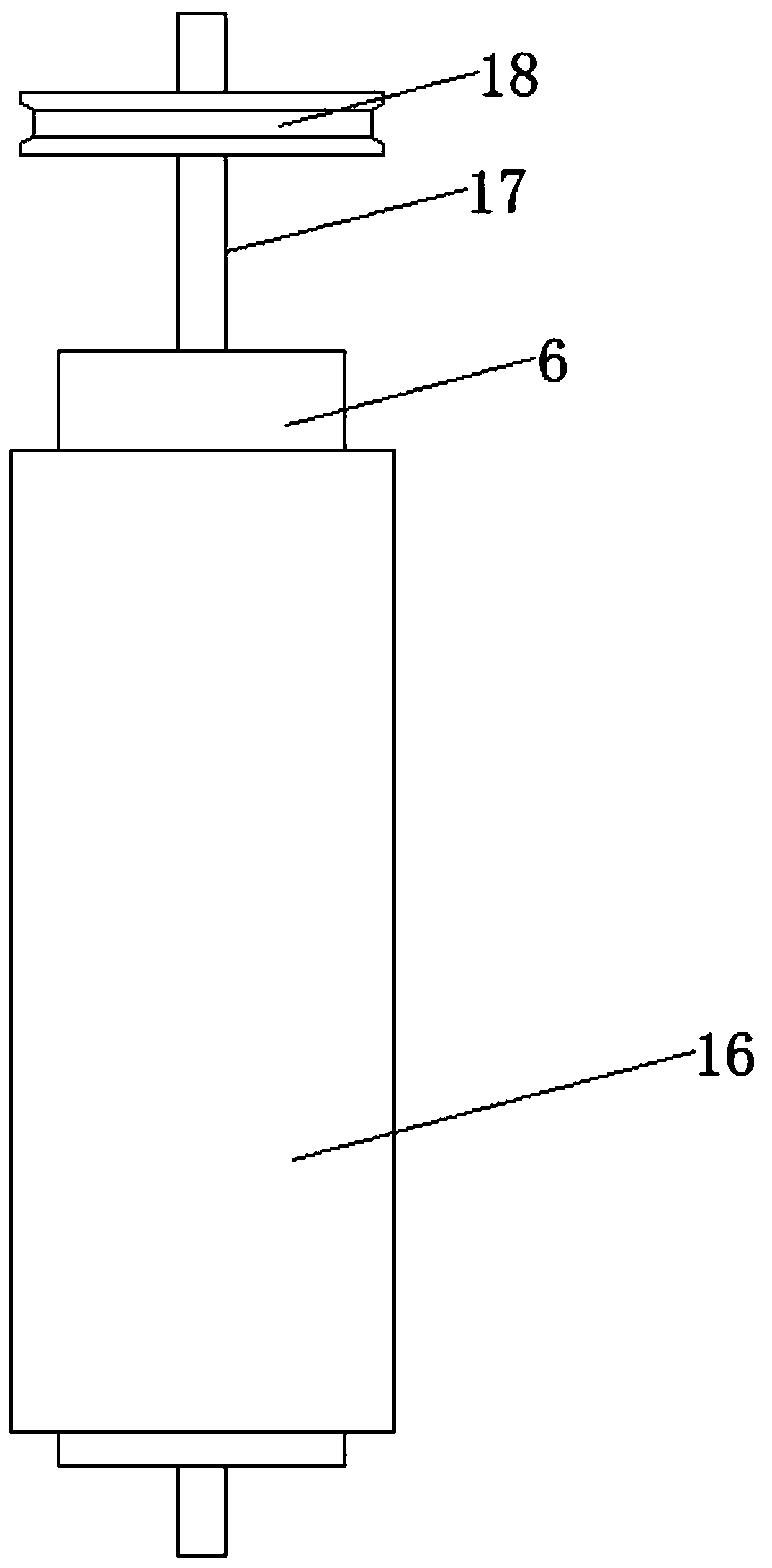

[0019] Please refer to the figure. In the embodiment of the present invention, a corrosion foil cleaning device includes a casing 1, a feed port 2, a discharge port 3, a lifting plate 4 and a circulating pump 15; the feed port 2 is opened in the casing On the left side wall of 1, the discharge port 3 is opened on the right side wall of the housing 1. The feed port 2 and the discharge port 3 are on the same horizontal plane, so that the corroded foil enters from the feed port 2. The corrosion after cleaning The foil is sent out from the discharge port 3; the lifting plate 4 is horizontally arranged in the housing 1, and the two ends of the lifting plate 4 are fixedly connected with a lifting device 21 that is telescopic in the vertical direction, and the height of the lifting plate 4 is adjusted by the lifting device 21 A plurality of brackets 5 are equidistantly arranged on the lower surface of the lifting plate 4, and a horizontal shaft 17 is rotatably connected to the bracket ...

Embodiment 2

[0023] The lower sides of the plurality of brush plates 10 are fixedly connected by a support rod 11, the lower side of the support rod 11 is fixedly connected with a plurality of springs 12, the lower ends of the springs 12 are fixedly connected to the bottom of the housing 1, and the brush plates 10 are supported by the springs 12 A vibration motor 22 is installed on the brush plate 10, and the vibration motor 22 drives the entire brush plate 10 to shake, thereby improving the cleaning effect of the corroded foil.

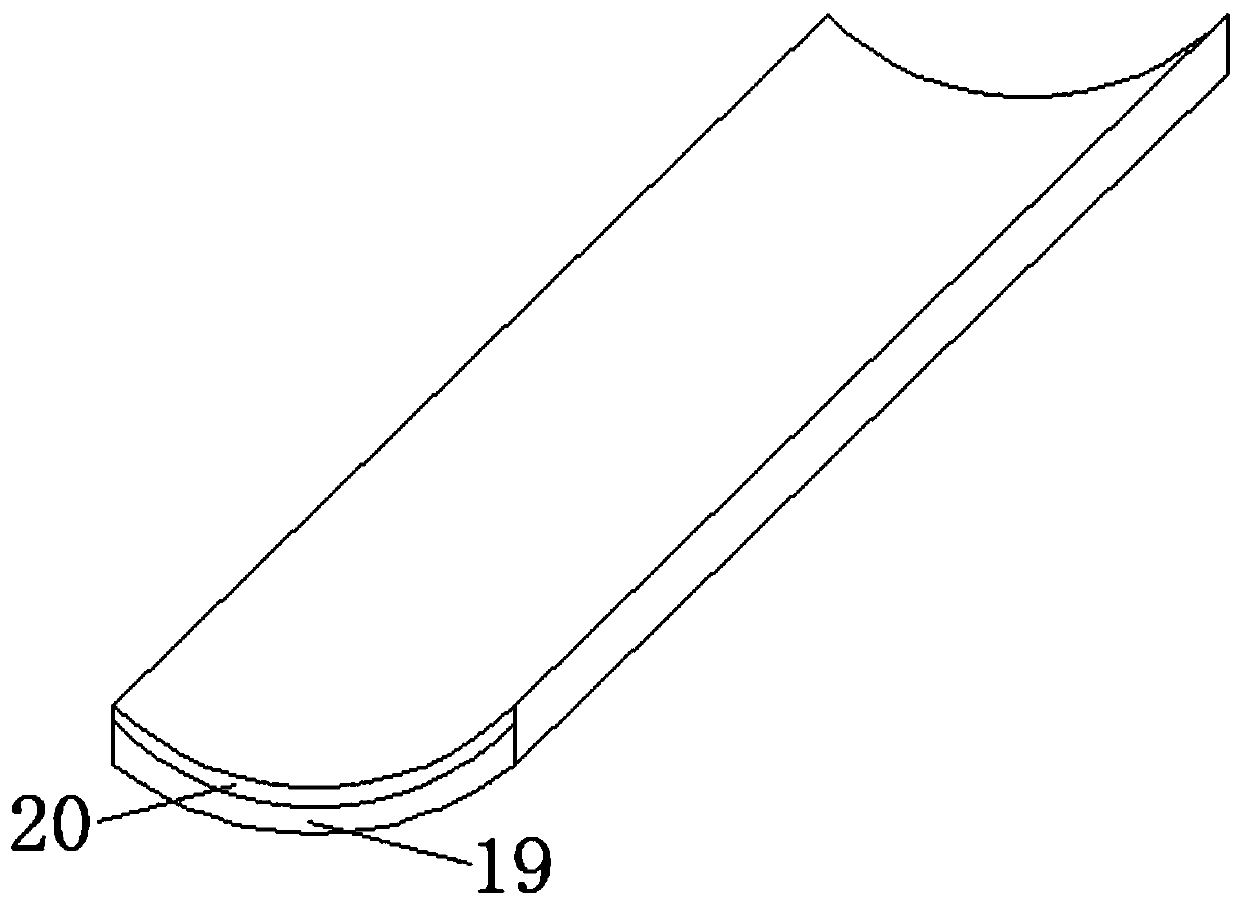

[0024] When in use, the corrosion foil enters from the feed port 2, alternately bypassing the internal driving roller 6 and guide roller 7, the driving roller 6 drives the corrosion foil to convey to the right, the driving roller 6 extends into the cleaning tank 8 and the internal deionization The upper surface of the corroded foil is in contact with the brush cover 16 on the surface of the driving roller 6, the upper surface is sprayed with deionized water through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com