Method and device for increasing the filling height of inner ribs in spin forming cylindrical parts with inner ribs

A technology of spinning forming and filling height, applied in the field of spinning forming processing, can solve the problems of the limit ring unable to achieve the axial flow of the material, the poor forming quality and stability of the workpiece, and the local bulge of the workpiece, so as to improve the versatility. and flexibility in use, avoiding diameter expansion and non-mold defects, and improving the filling height of inner ribs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

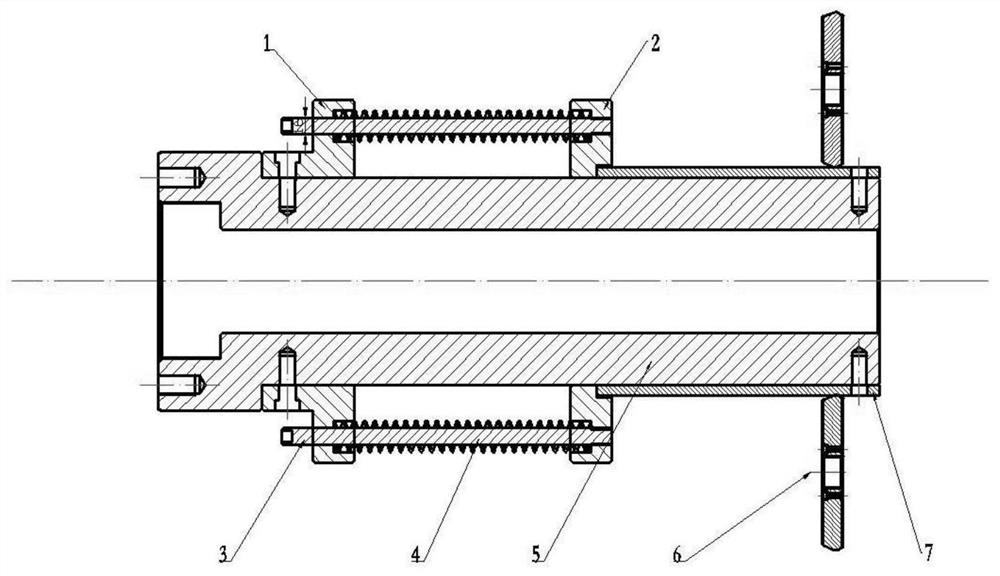

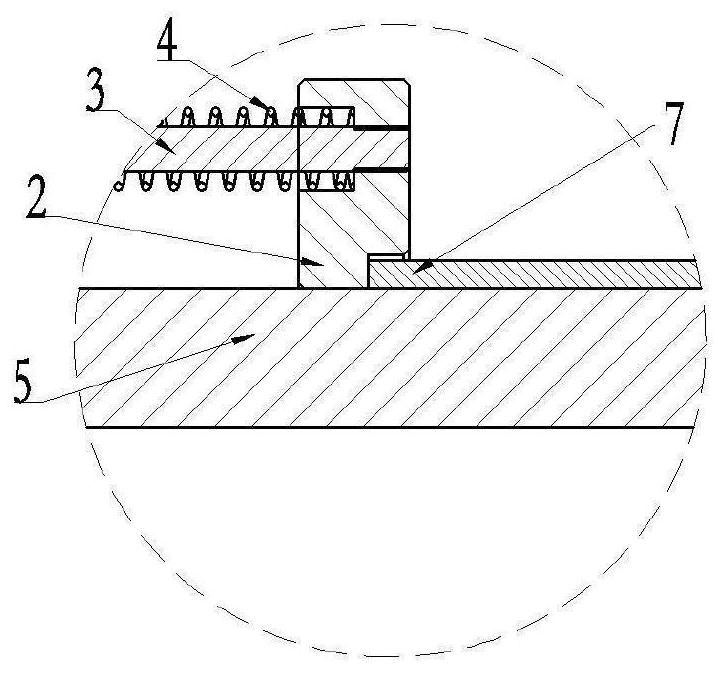

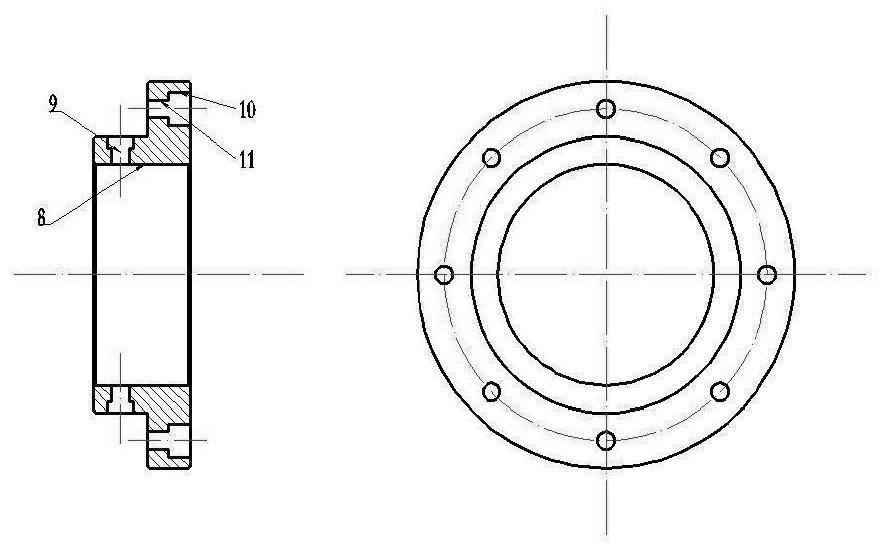

[0023] A method of increasing the filling height of inner ribs in the spinning forming of cylindrical parts with inner ribs of the present invention, such as figure 1 As shown, the method is to add a fixed ring 1 and an axial restraint ring 2 on the existing spinning mandrel 5 of the cylindrical part with internal ribs, the fixed ring 1 and the spinning mandrel 5 are fixedly connected by threads, and the shaft The confinement ring 2 and the fixed ring 1 are connected through a support rod 3 covered with a compression spring 4; one end of the support rod 3 is connected with the axial threaded through hole 15 on the axial confinement ring 2 by threads, and the other end passes through the fixed The axial through hole 11 on the ring 1 can move axially along the spinning mandrel 5 together with the axial restricting ring 2 during the spinning for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com