Air spring vibration isolator based on magnetic control damping

An air spring and vibration isolator technology, applied in the direction of spring/shock absorber, spring, shock absorber, etc., can solve the problem of poor adaptability to vibration environment, less than ideal vibration isolation performance, and can not further expand the air spring vibration isolator project Application scope and other issues, to achieve the effect of optimizing vibration isolation performance, improving low-frequency vibration isolation performance, and improving vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical scheme and advantages of the present invention clearer, detailed implementation has been provided, and the present invention will be further described in detail below in conjunction with the accompanying drawings:

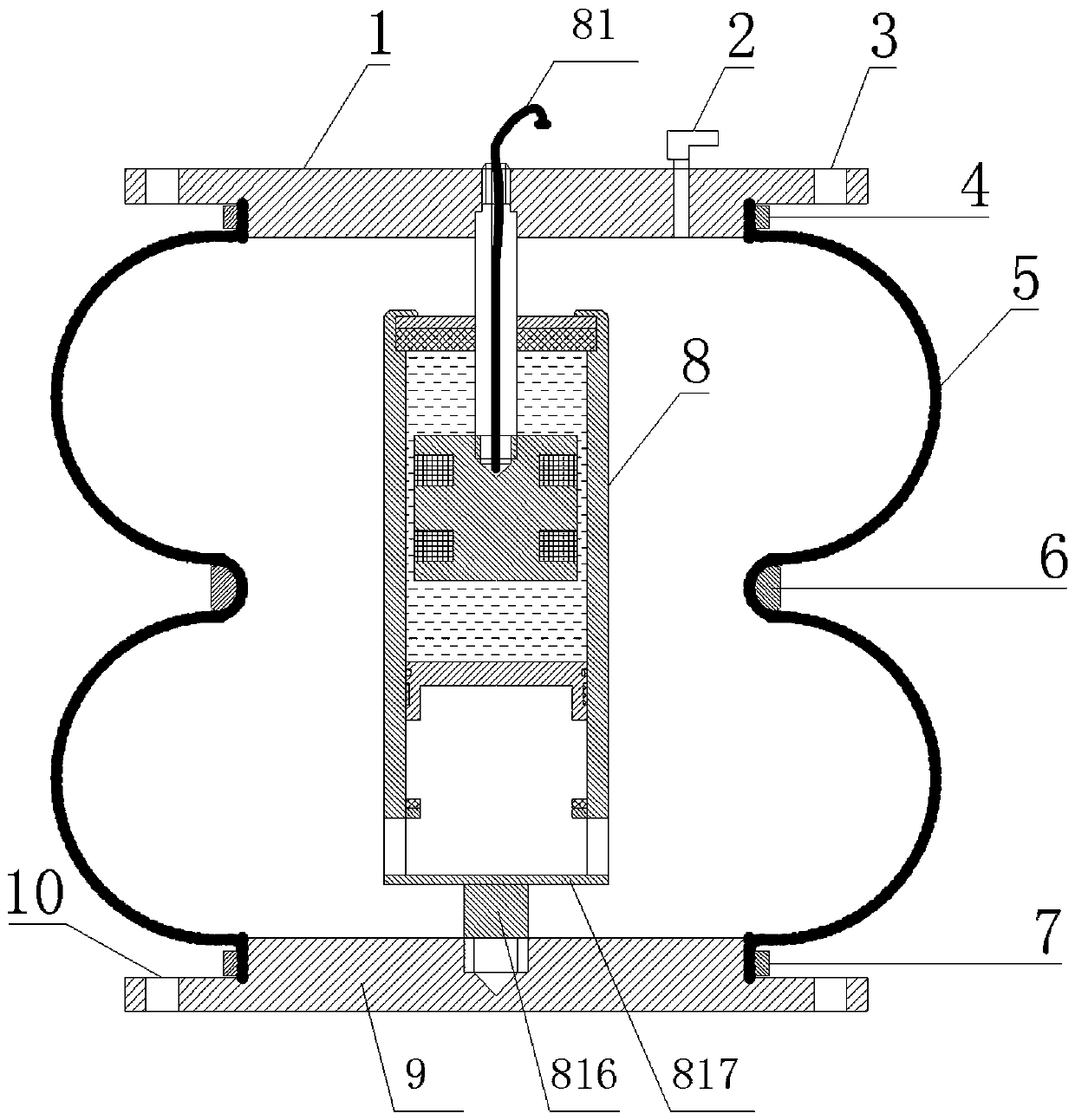

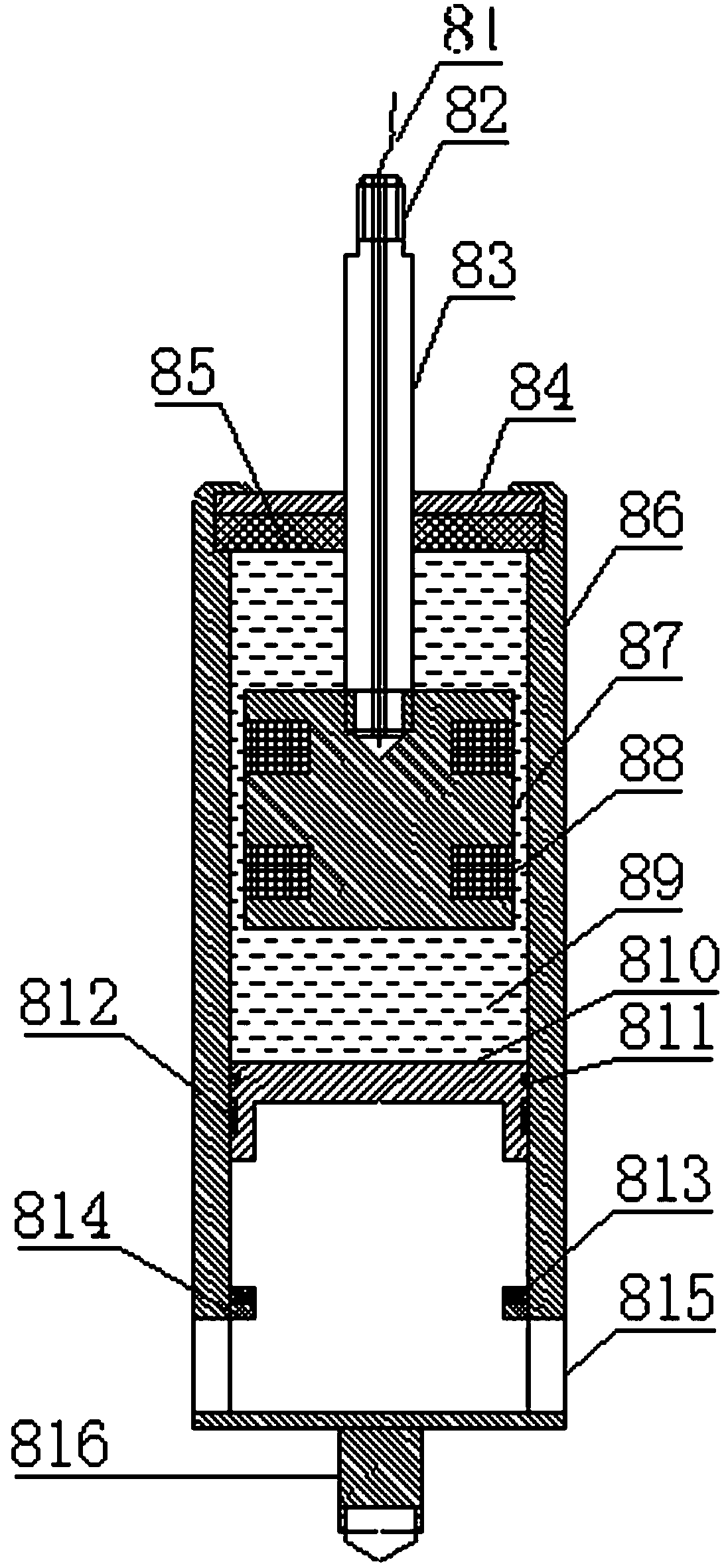

[0020] see figure 1 and figure 2 , this embodiment discloses an air spring vibration isolator based on magnetic control damping, which is composed of two parts: an air spring and a magnetic control damping device 8 . The air spring includes a first end sealing plate 1, a second end sealing plate 9 and a curved capsule 5, the upper end of the curved capsule 5 is fixedly connected to the first end sealing plate 1, and the lower end of the curved capsule 5 is connected to the second end sealing plate 5. The end seal plate 9 is fixedly connected, and the first end seal plate 1, the curved bag 5, and the second end seal plate 9 form a closed and sealed cavity, and the air spring is provided with an inflation and deflation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com