Steel twisted rope reeling off device

A rope release device and steel strand rope technology, which is applied in the field of steel strand rope release device, can solve the problems of personal injury of operators, complicated stress, and high strength of steel strand rope, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

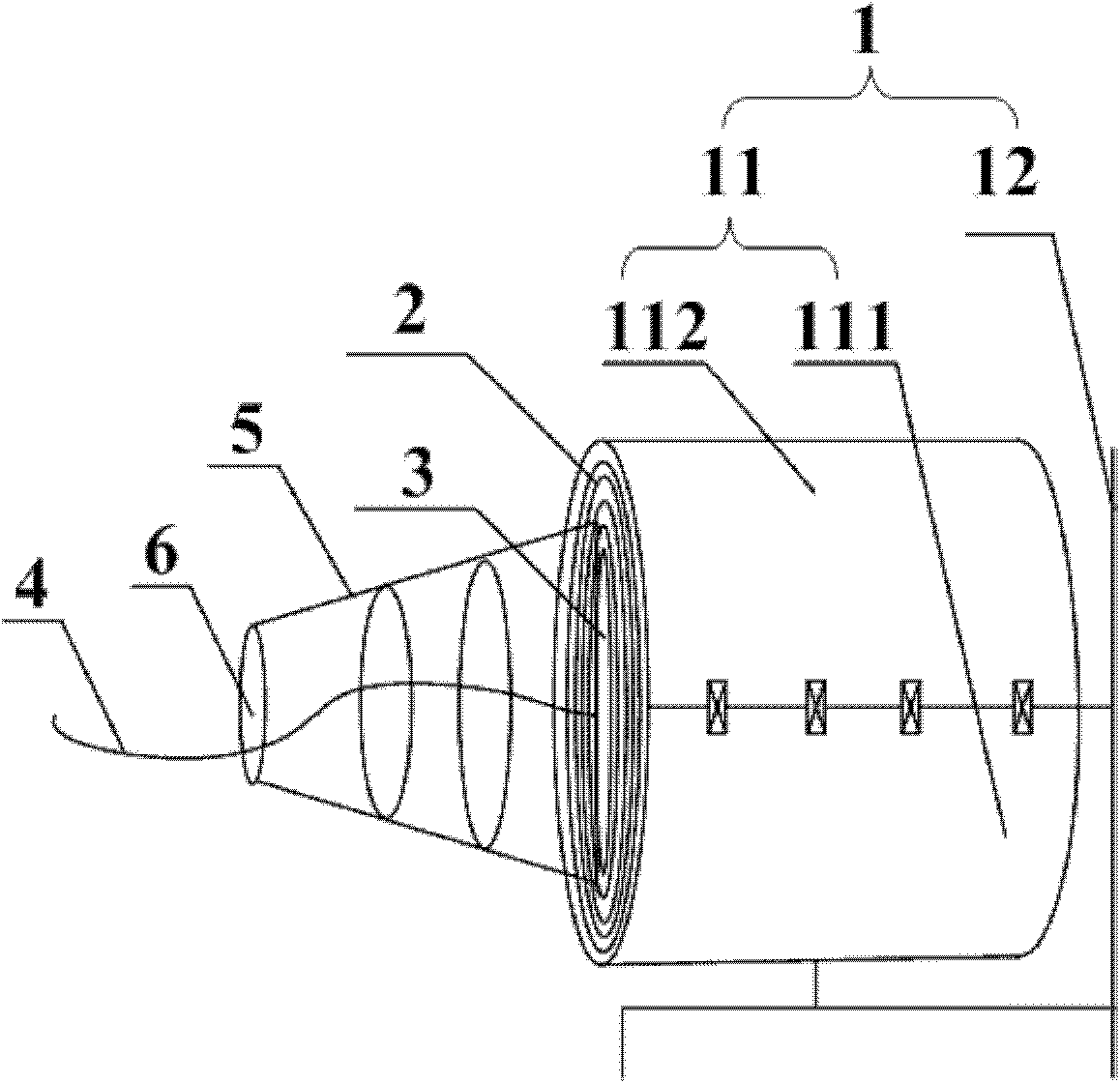

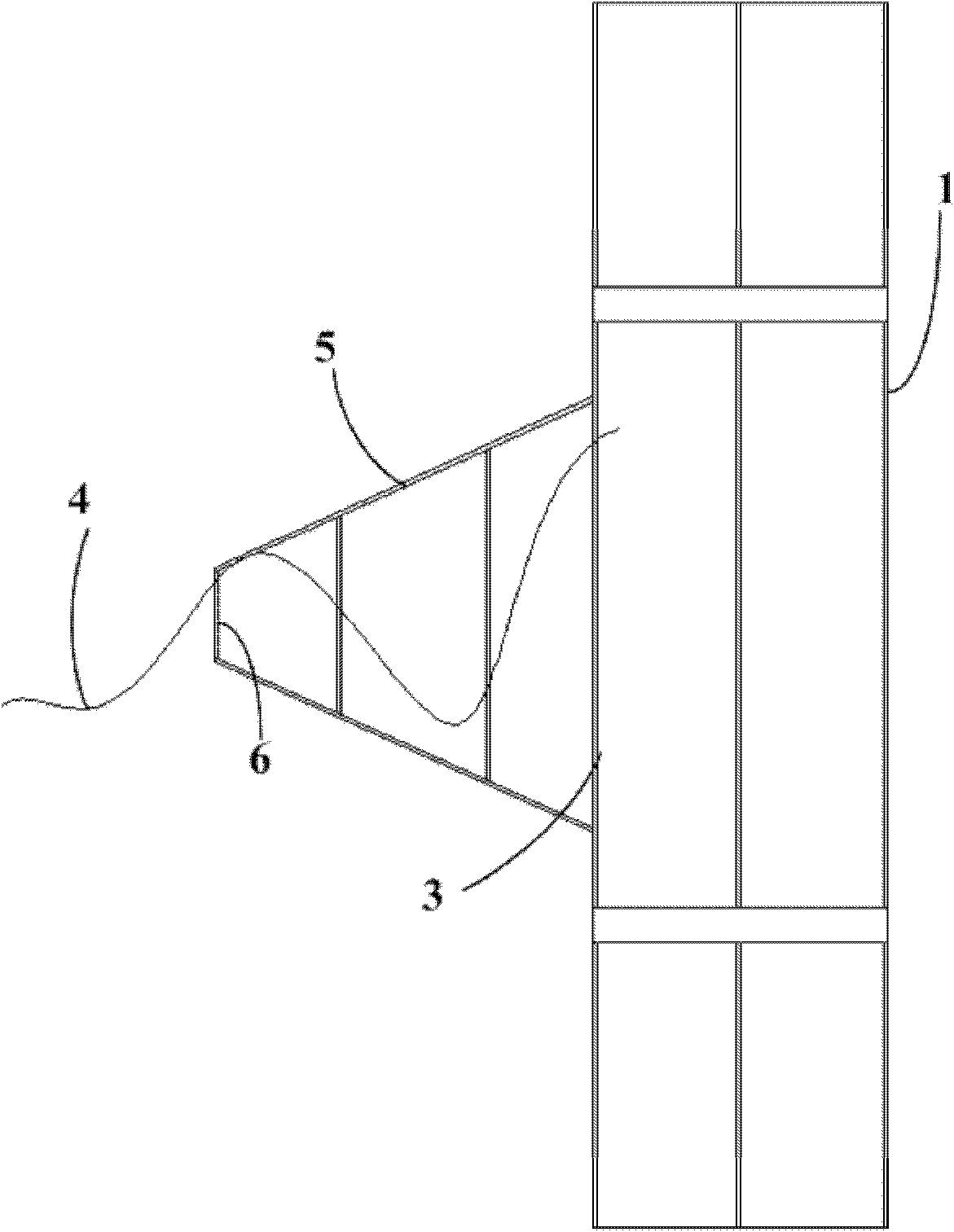

[0045] figure 1 It is a schematic diagram of the steel strand rope releasing device provided by Embodiment 1 of the present invention. Embodiment 1 of the present invention provides a steel strand rope unwinding device, which includes a fixing device 1, the fixing device 1 is used to surround the outer side of the steel strand rope roll 2 coiled in coils, and limit the radial expansion of the steel strand rope roll 2; A steel strand rope outlet 3 is provided on the fixing device 1, and the steel strand rope outlet 3 is used to stretch out the steel strand rope 4 of the steel strand rope roll 2, so that the steel strand rope 4 stretched out from the center of the steel strand rope roll 2 to The edges spread out.

[0046] On the basis of the above-mentioned technical scheme, preferably: the steel strand rope release device also includes a resistance device, the resistance device is fixedly connected with the end face of the fixing device 1, and is located outside the steel stra...

Embodiment 2

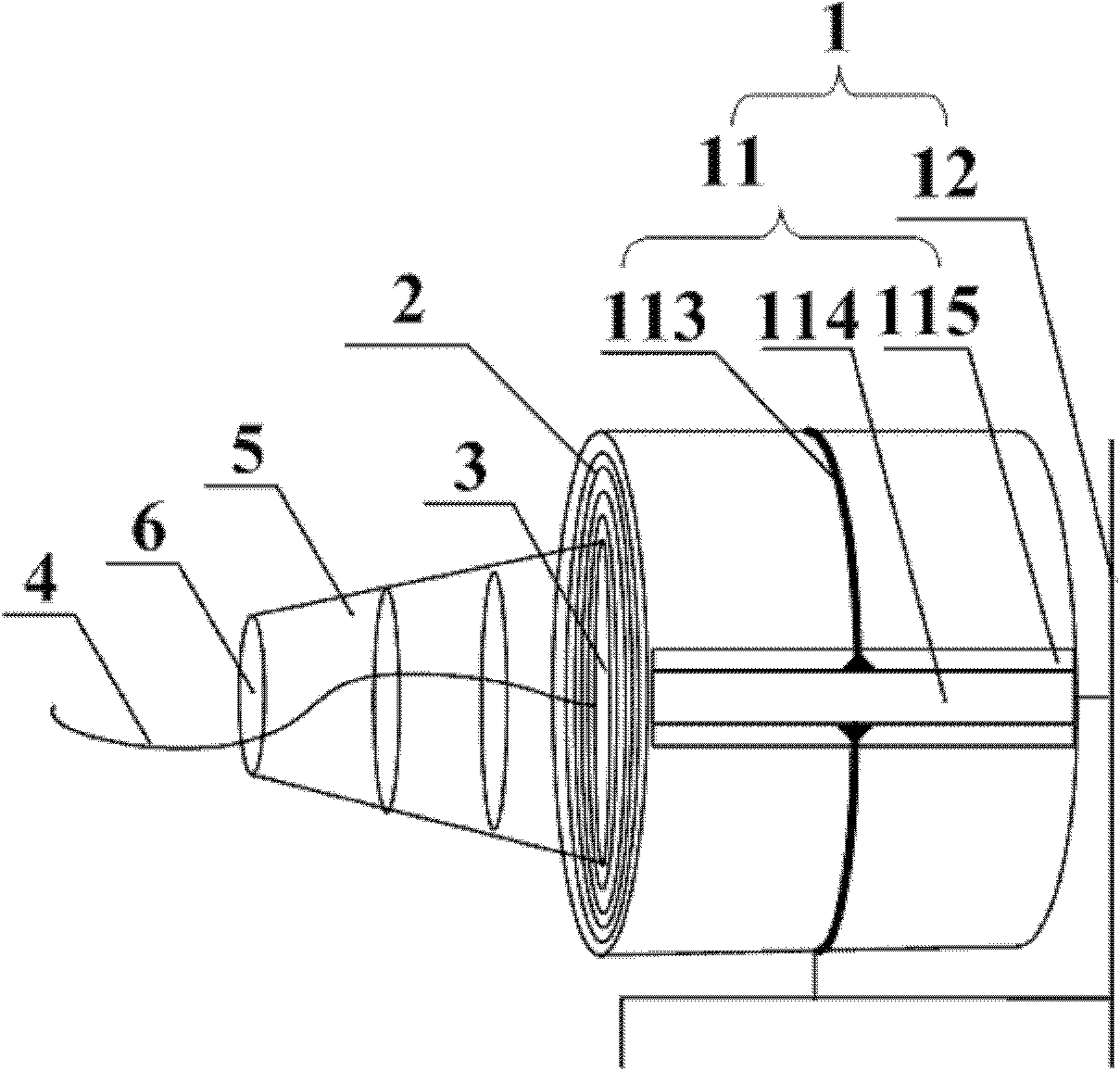

[0058] Figure 2AIt is a schematic diagram of the steel strand rope releasing device provided by Embodiment 2 of the present invention. Figure 2B for Figure 2A A schematic top view of the part. Figure 2C for Figure 2A Partial left view schematic diagram of . The difference between the second embodiment of the present invention and the first embodiment lies in that the implementation of the steel strand fixing structure 11 is different. In this embodiment, the steel strand fixing structure 11 includes several circular arc rods 113 and several connecting channel steels 114; Intersect to form a cylindrical press frame; the length of the connecting channel steel 114 along the axial direction of the steel strand rope roll 2 is not less than the stacking height of the steel strand rope roll 2 .

[0059] The structure of the arc rod and the connecting channel steel is simple, which is convenient for processing and manufacturing, and the formed cylindrical press frame is light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com