Inner and outer wall reinforced soft mechanical arm and manufacturing method thereof

A robotic arm and software technology, applied in the directions of manipulators, claw arms, manufacturing tools, etc., can solve the problems of reducing the efficiency of expansion and bending per unit volume, difficult to adapt to the underwater working environment, complex structure of the software robotic arm, etc., to achieve a simple structure. , cost-effective, light-weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

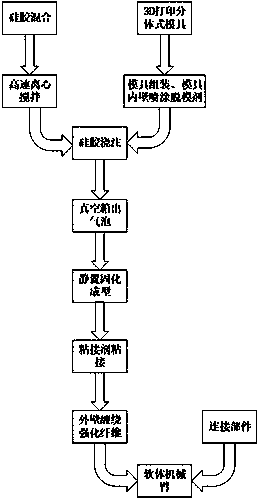

Method used

Image

Examples

Embodiment Construction

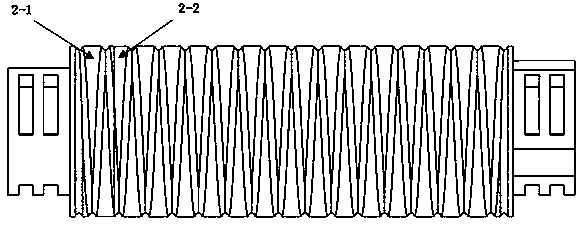

[0054] refer to Figure 1 to Figure 9 , the present invention is made up of several silica gel units through connecting parts, and each silica gel unit has a group of helical grooves 5-3 with the opposite direction of rotation and the same number of turns on the outer wall of the middle part, which are used to wind reinforcing fibers; at both ends of the silica gel unit They are all cylinders with a diameter smaller than the middle part, and there are evenly distributed step-shaped grooves 5-2 on the cylinders, and there are water inlets 5-1; the cavity section of the silica gel unit is three fan-shaped evenly distributed around the axis, And there is a through hole running through the silicone unit.

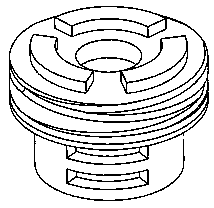

[0055] The connecting part is composed of three petals with the same structure, which are 3D printed with PLA material; the three petal connecting parts form a whole, and the inner surface is composed of evenly distributed step-shaped protrusions 6-1, which are used to connect two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com