Target object conveying method and device

A target object, target technology, applied in the field of target object transmission method and device, can solve the problem of low transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

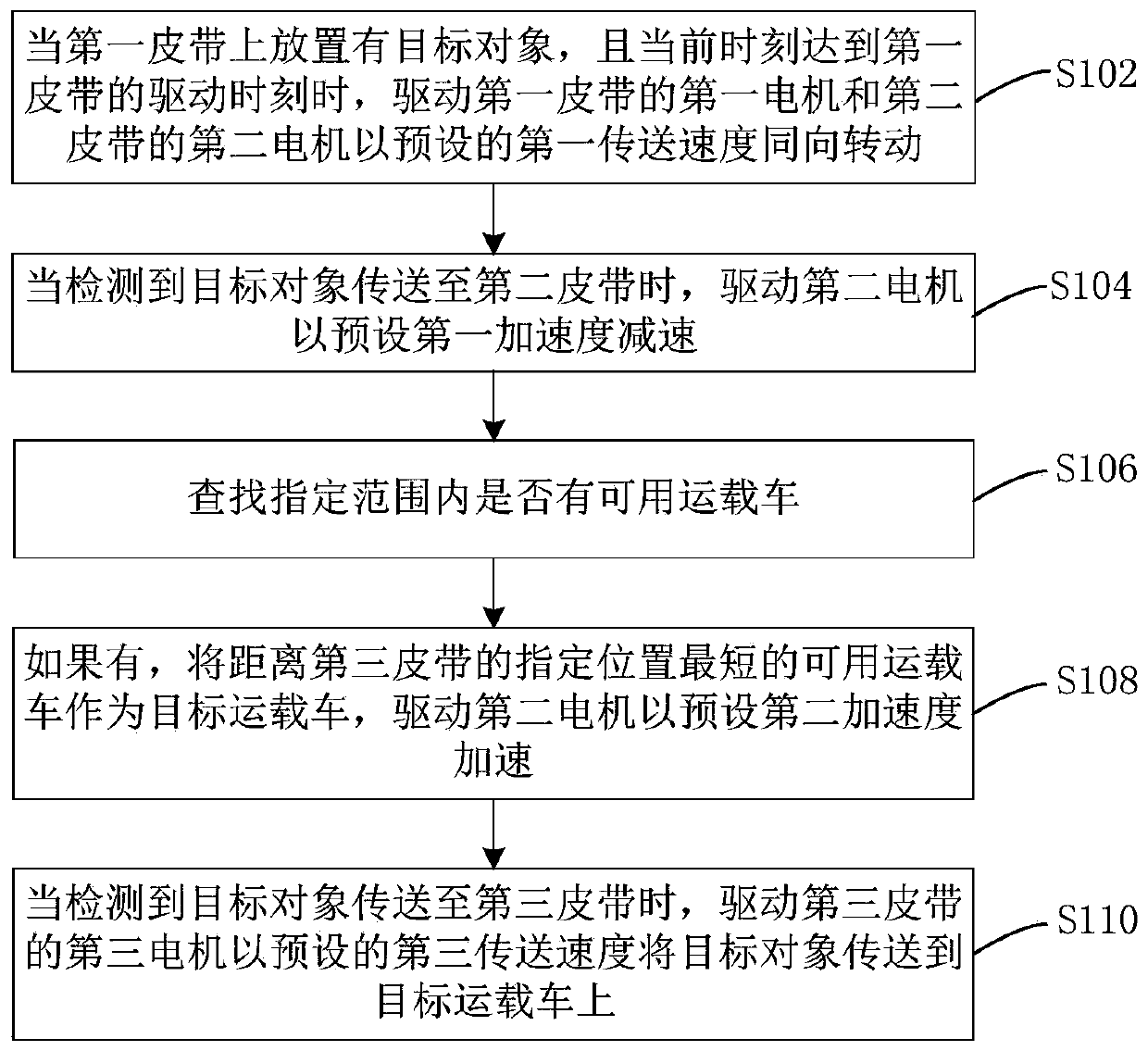

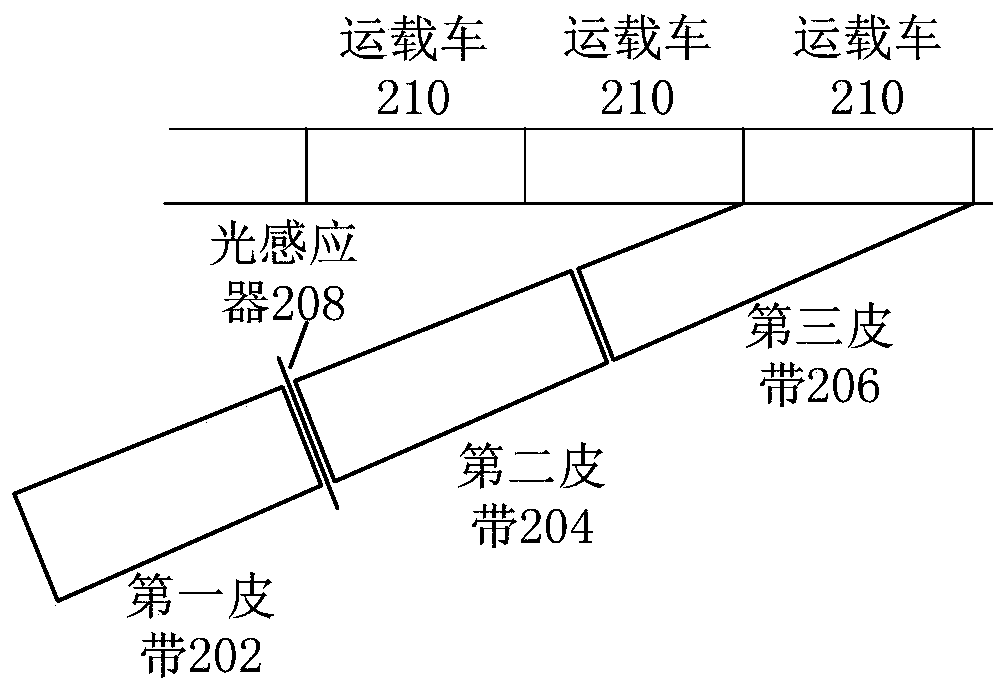

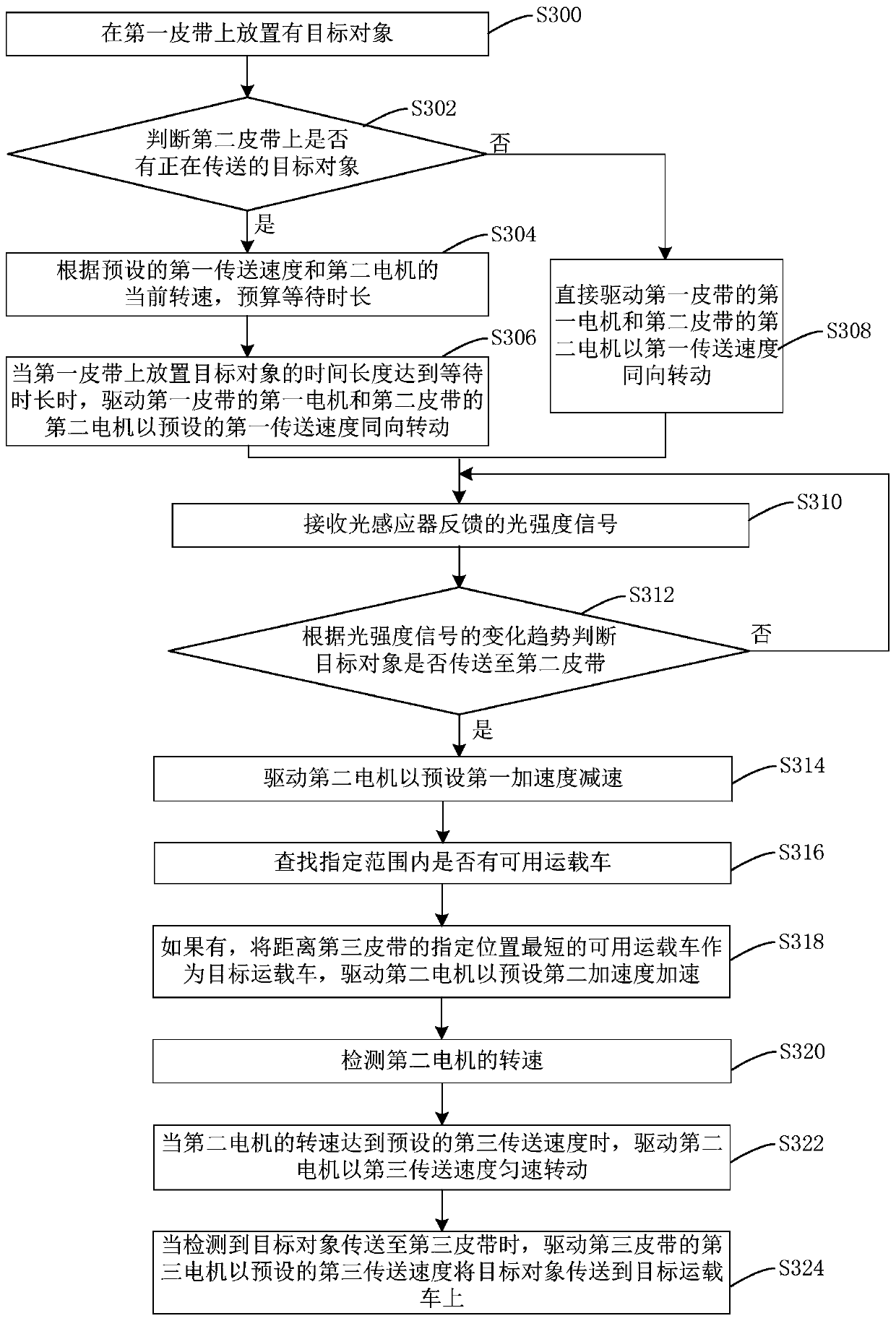

[0030] This embodiment provides a target object transfer method, refer to figure 1A flow chart of a target object transmission method is shown. The method is applied to the controller, and the controller is connected with the transmission mechanism. The transmission mechanism includes sequentially connecting the first belt, the second belt and the third belt. For ease of understanding, figure 2 A schematic diagram of a belt layout of a transmission mechanism is shown, including a first belt 202 , a second belt 204 and a third belt 206 . The above-mentioned connection of the first belt, the second belt and the third belt refers to a connection method arranged sequentially in the conveying direction, not a physical or mechanical connection.

[0031] The method includes the following steps:

[0032] Step S102, when the target object is placed on the first belt, and the current time reaches the driving time of the first belt, the first motor driving the first belt and the secon...

Embodiment 2

[0083] This embodiment also provides a target object transmission device, refer to Figure 4 A structural schematic diagram of a target object transmission device is shown, the device is applied to the controller, the controller is connected to the transmission mechanism, and the transmission mechanism includes sequentially connecting the first belt, the second belt and the third belt, and the device includes:

[0084] The transmission driving module 402 is configured to drive the first motor of the first belt and the second motor of the second belt at a preset first speed when the target object is placed on the first belt and the current time reaches the driving time of the first belt. - Rotate in the same direction at the transmission speed;

[0085] A deceleration drive module 404, configured to drive the second motor to decelerate with a preset first acceleration when it is detected that the target object is transmitted to the second belt;

[0086] A search module 406, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com