Joint of raft foundation and pile foundation tie

A technology of raft foundation and pile foundation, which is applied in the direction of foundation structure engineering and construction, and can solve the problems of waste of materials, leakage of concrete into pile holes, and questionable degree of firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

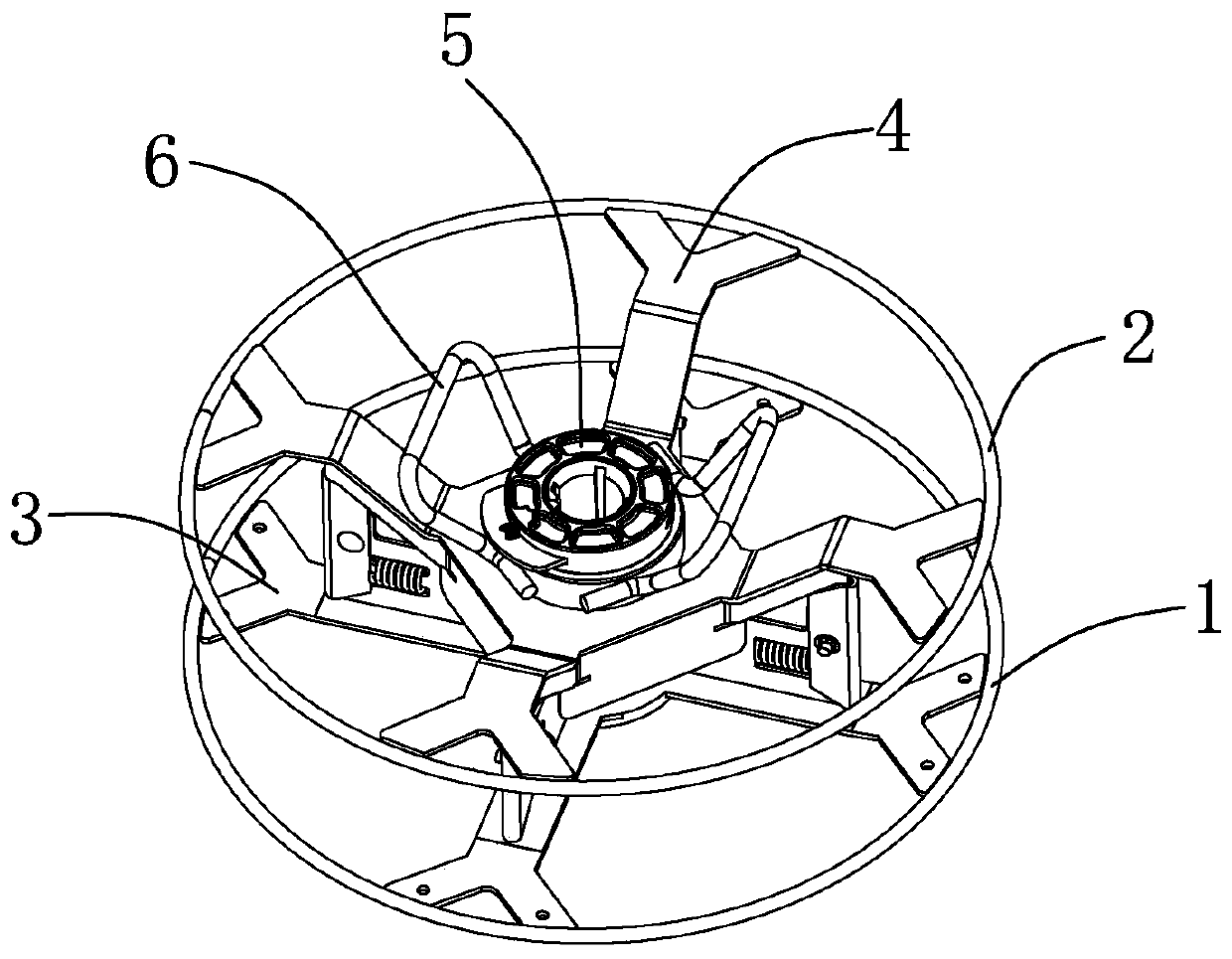

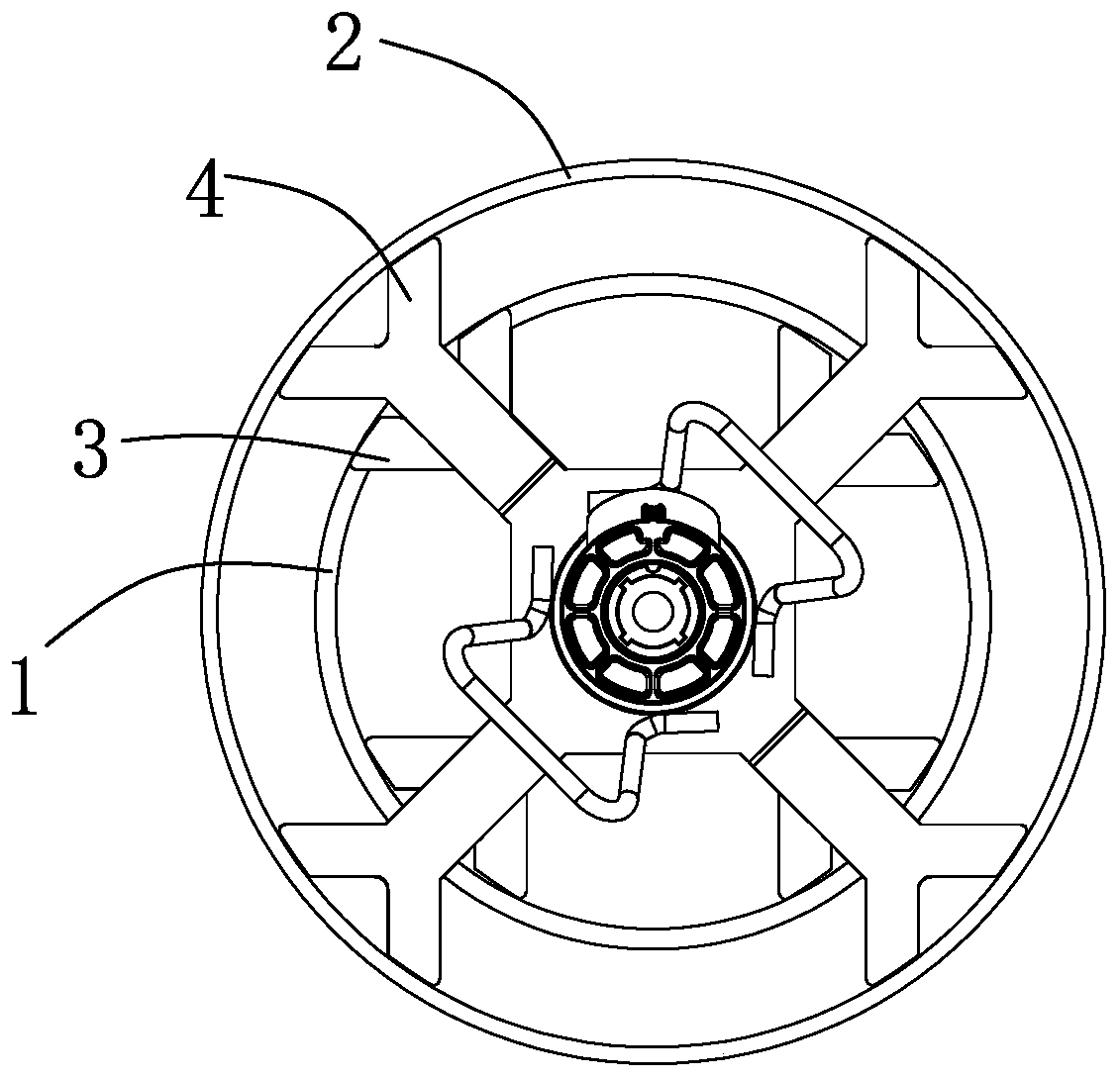

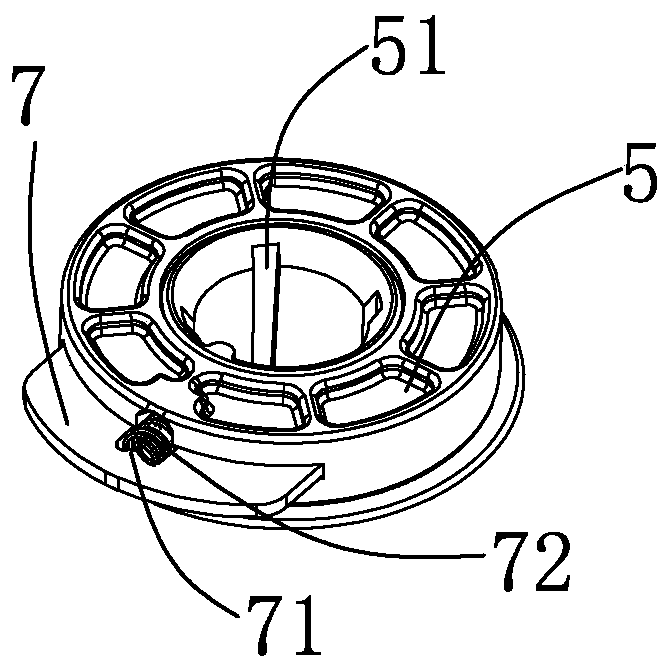

[0026] Embodiment: a raft foundation and a pile foundation pouring tie knot, its main structure includes: small diameter steel ring 1, large diameter steel ring 2, bottom Y-shaped strut 3, top Y-shaped strut 4, cylinder Base 5, steel wire cableway groove 51, steel bar support 6, side clamping steel plate 7, spring hole groove 71, clamping spring seat 72, cylindrical cap square seat 8, upper bar-shaped inclined plate 81, lower bar-shaped inclined plate 82. Strut 83, steel wire mesh 9, steel wire 10, spring seat 11, tube strip 12, bottom Y-shaped strut 3 is welded on the four equally divided positions of the bottom of the cylinder base 5, and the The cylindrical base 5 is socketed in the cylindrical bearing platform square seat 8 and the two are fixed. The top Y-shaped struts 4 are evenly distributed on the top four corners of the cylindrical bearing platform square seat 8; A small-diameter steel ring 1 is welded on the outer edge of the bottom Y-shaped strut 3, and a large-diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com