A kind of preparation method of high nickel matte oxidized calcine

A technology of nickel matte and calcination, which is applied in the field of metallurgy, can solve the problems of difficulty in obtaining high nickel matte oxidized calcine, failure of normal production, and increased costs, and achieve the effects of avoiding ignition and softening, solving furnace caking problems, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the high matte oxidized calcine in this embodiment includes the following steps: crush the high matte in a crusher to obtain small particles of high matte; finely grind the small particles of high matte in a vibration mill, and grind the finely ground The high nickel matte powder is passed through a 200-mesh sieve; the finely ground high nickel matte is placed in a burning boat, placed in the middle of the tube furnace, and heated at a rate of 5°C / min in a pure oxygen atmosphere. After reaching 520°C, the temperature is kept for 5 hours; In the atmosphere, the temperature is increased to 820°C at a rate of 2°C / min, and the temperature is kept for 5 hours; after the material is cooled with the furnace, a high matte nickel oxide calcine is obtained.

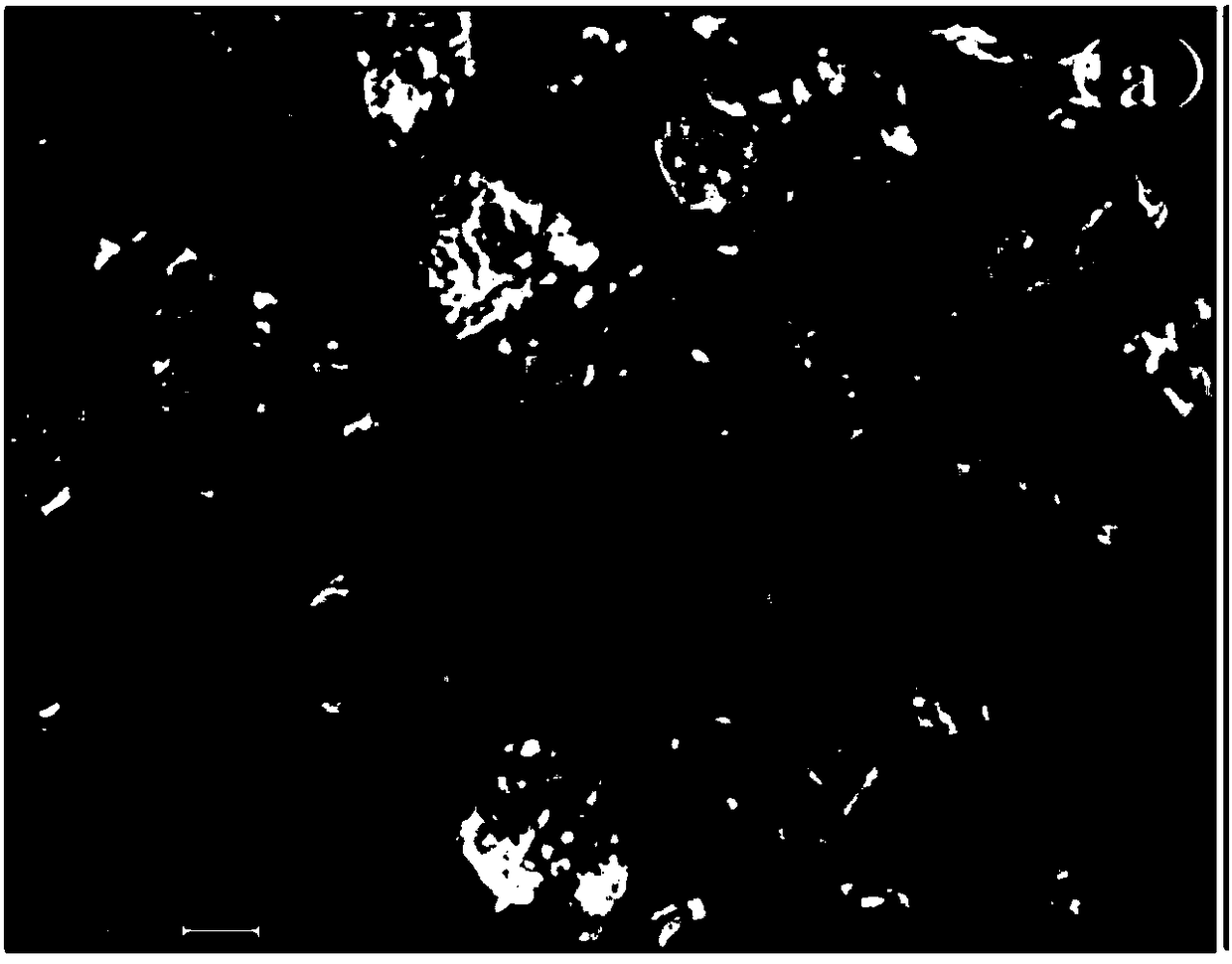

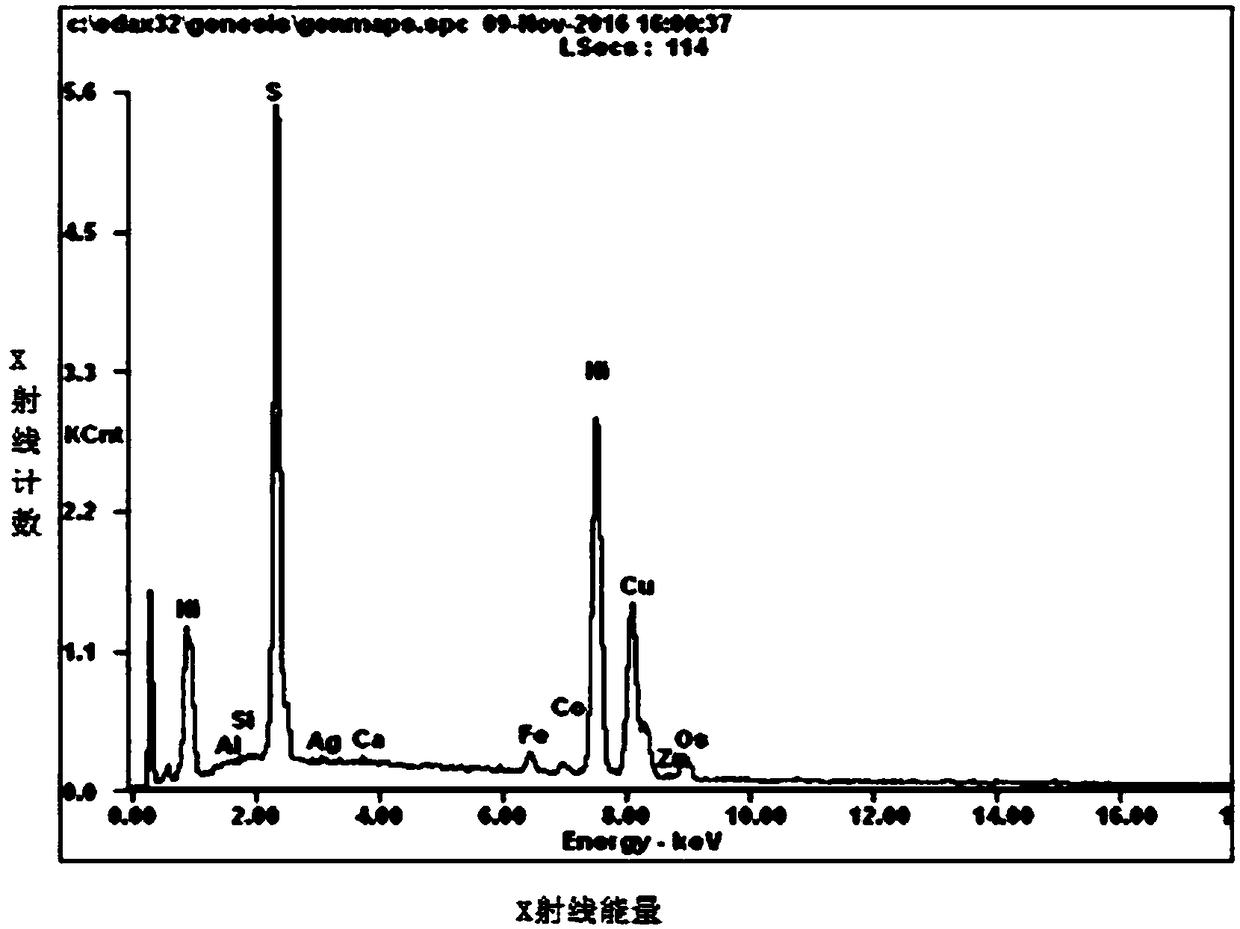

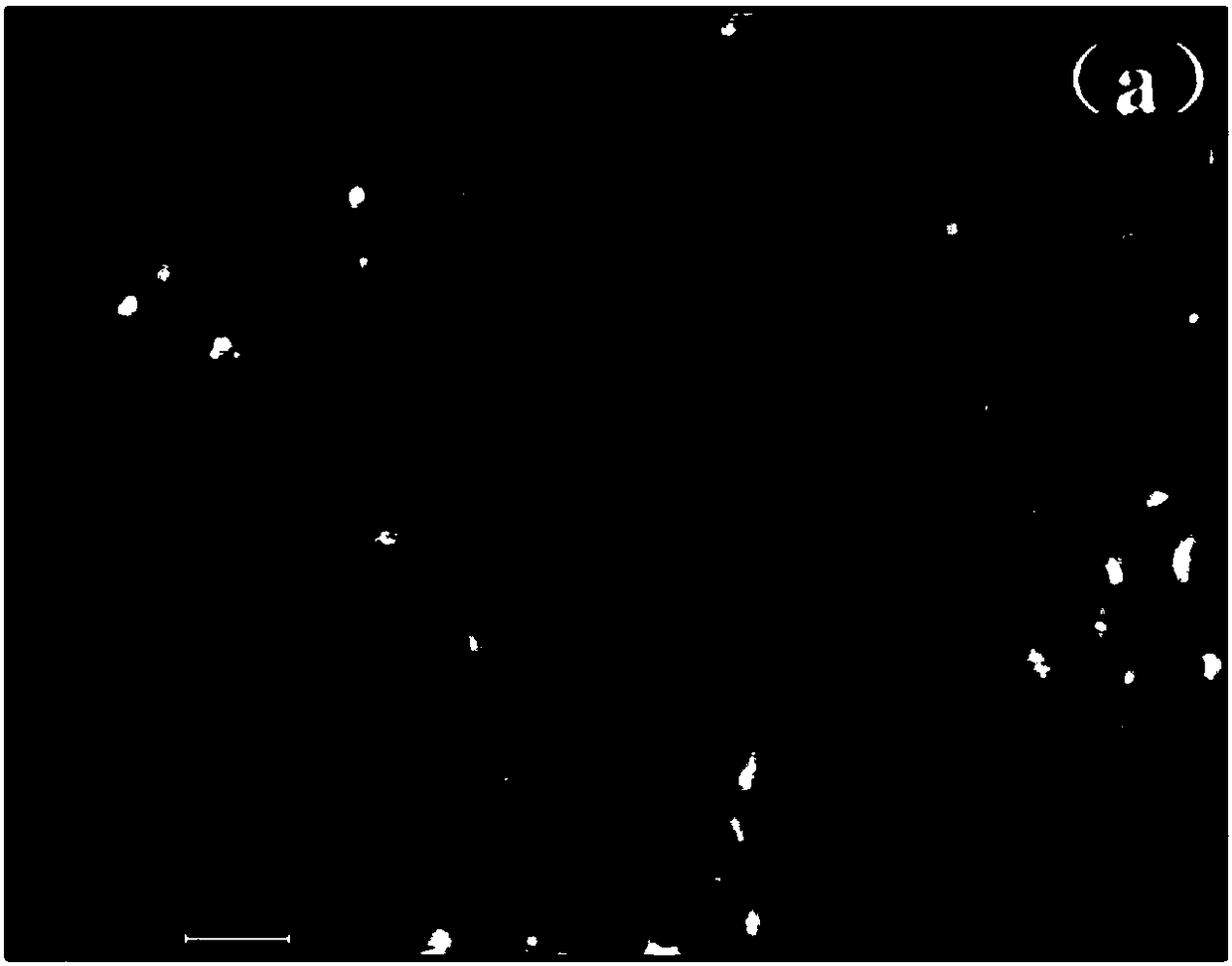

[0031] Such as figure 1 , figure 2 As shown, the finely ground high nickel matte powder has a finer particle size, more sulfur elements and evenly distributed in the high matte nickel, while the copper...

Embodiment 2

[0035] The preparation method of the high matte oxidized calcine in this embodiment includes the following steps: crush the high matte in a crusher to obtain small particles of high matte; finely grind the small particles of high matte in a vibration mill, and grind the finely ground The high nickel matte powder is passed through a 300-mesh sieve; the finely ground high nickel matte is placed in a burning boat, placed in the middle of the tube furnace, heated to 540°C at a rate of 15°C / min in a pure oxygen atmosphere, and then kept for 15 hours; the oxygen content is Under a 50% oxygen atmosphere, the temperature is raised to 850°C at a rate of 3°C / min and the temperature is maintained for 10 hours; after the materials are cooled with the furnace, the high matte nickel oxide calcine is obtained. The obtained high matte oxidized calcine was subjected to inductively coupled plasma (ICP) detection, and the sulfur content of the high matte oxidized calcine was 0.048%.

Embodiment 3

[0037] The preparation method of the high matte oxidized calcine in this embodiment includes the following steps: crush the high matte in a crusher to obtain small particles of high matte; finely grind the small particles of high matte in a vibration mill, and grind the finely ground The high nickel matte powder is passed through a 100-mesh sieve; the finely ground high matte nickel is placed in a burning boat, placed in a muffle furnace, heated to 560°C at a rate of 18°C / min in an air atmosphere, and then kept for 10 hours; The temperature is raised to 870°C at a rate of 5°C / min and the temperature is maintained for 15 hours; after the materials are cooled with the furnace, the high matte nickel oxide calcine is obtained. The obtained high matte oxidized calcine was subjected to inductively coupled plasma (ICP) detection, and the sulfur content of the high matte oxidized calcine was 0.052%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com