Feed beam, rock drill unit and method of manufacturing feed beam

A feed and rock drilling technology, applied in the direction of drilling equipment and methods, chemical instruments and methods, earth drilling and mining, etc., to achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

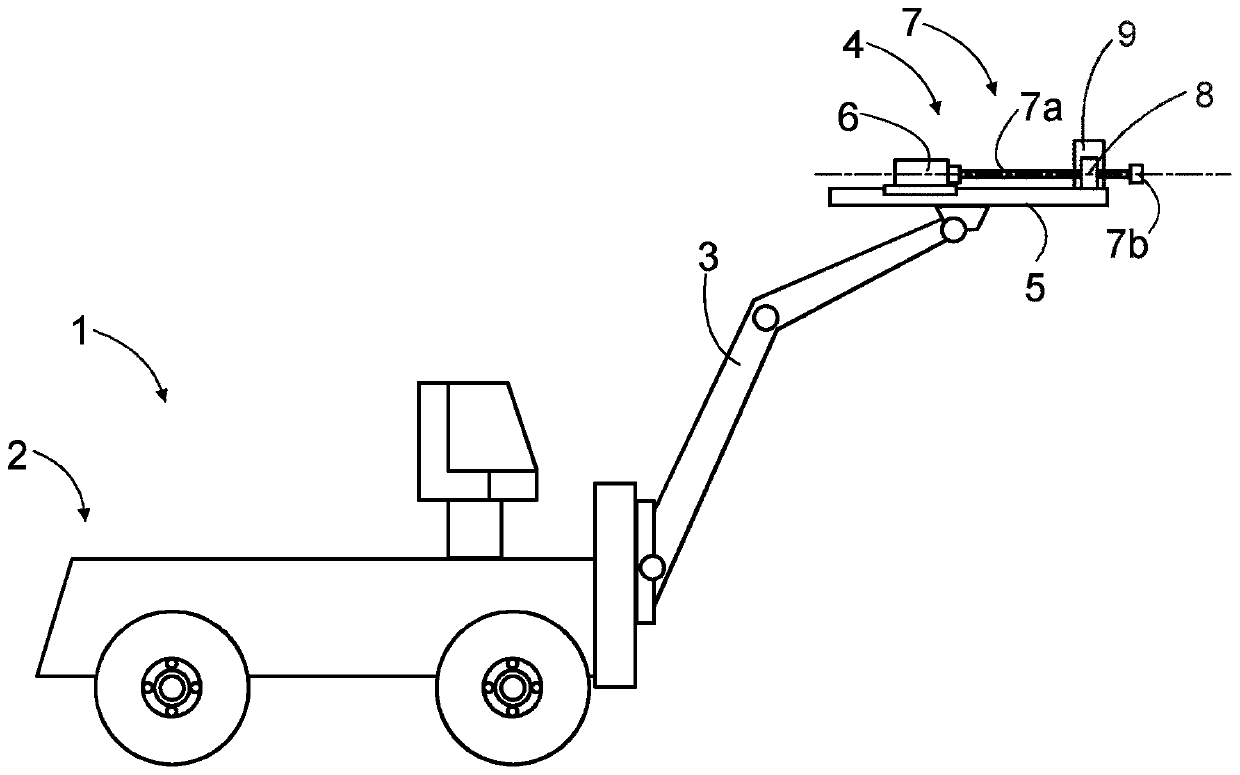

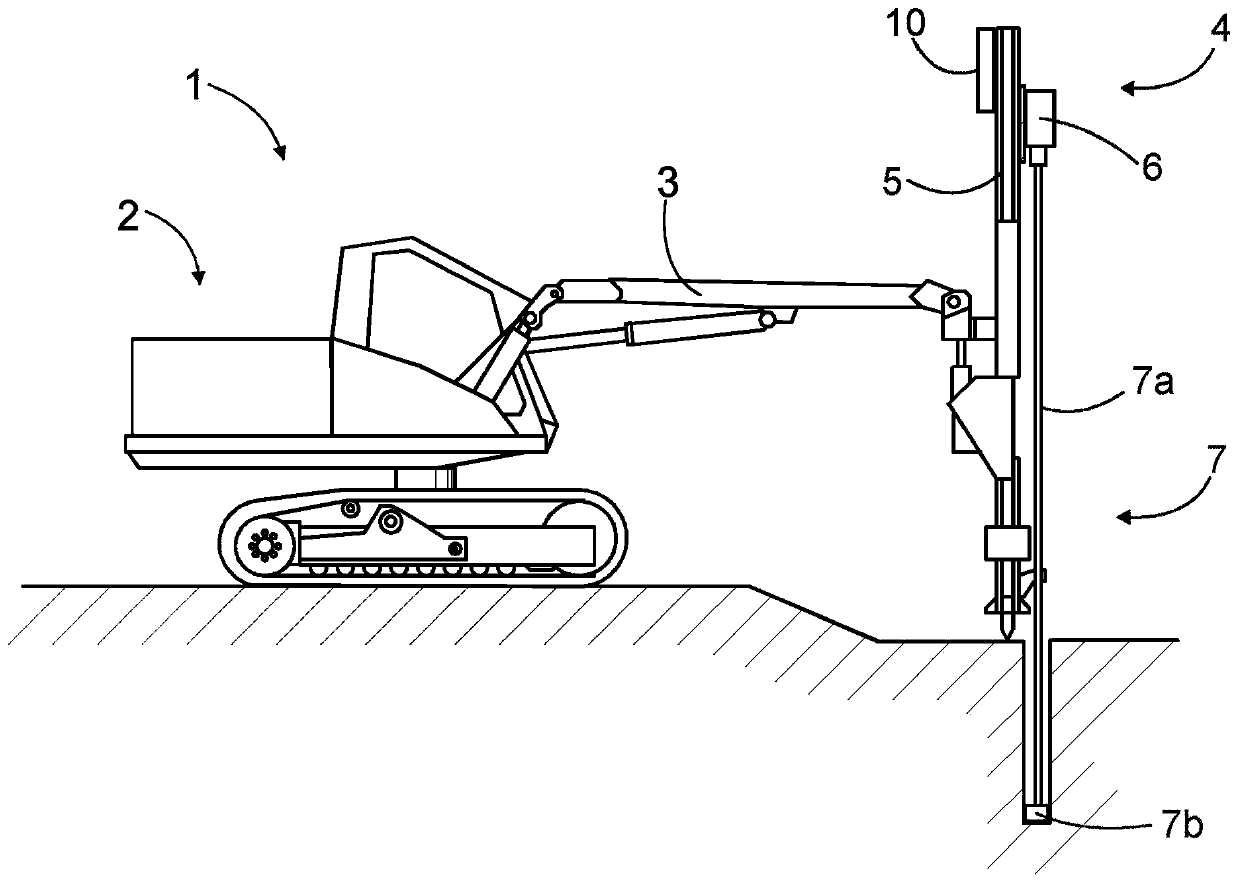

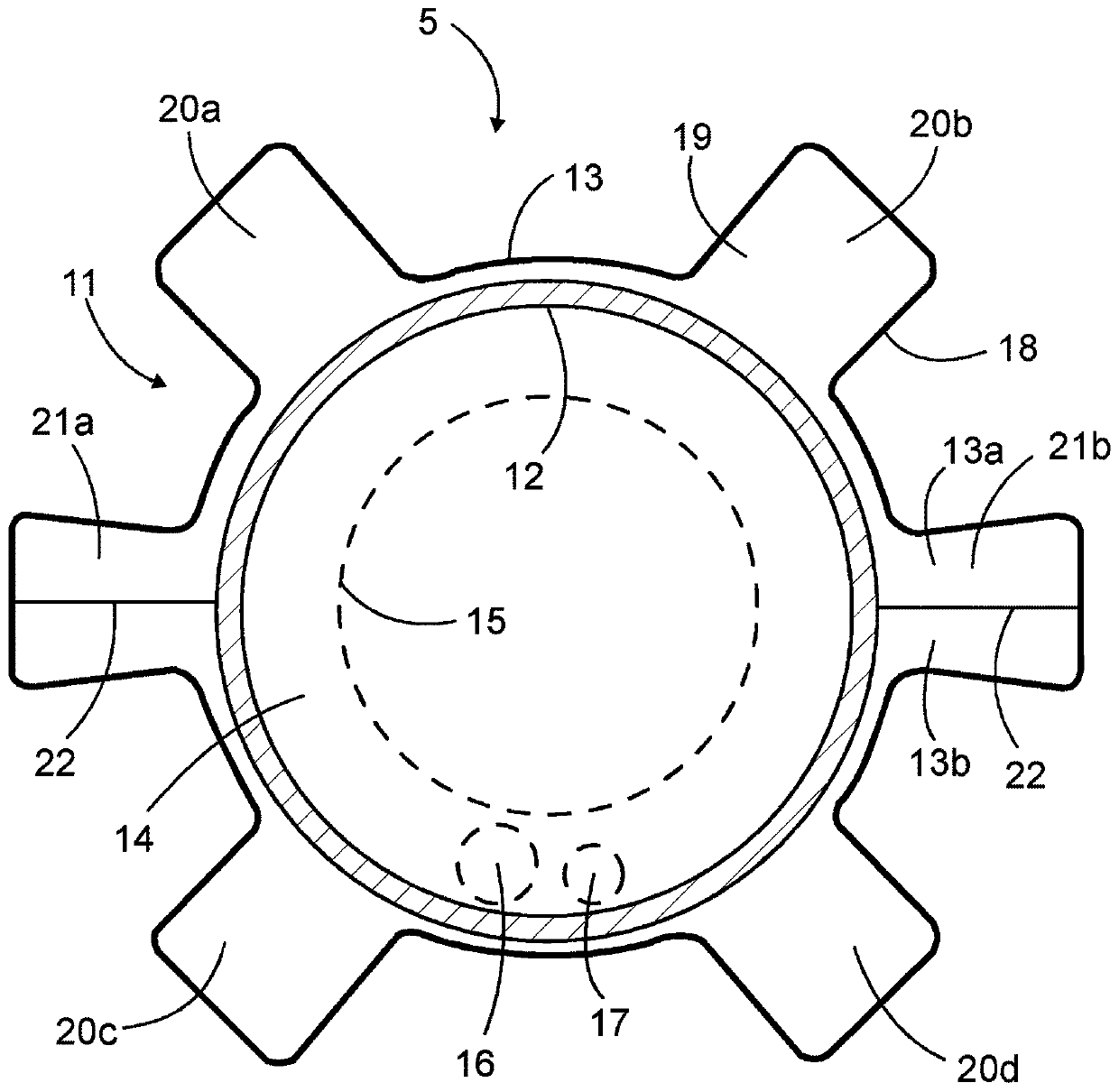

[0056] figure 1 A rock drilling rig 1 is shown as an example of a mining vehicle comprising a feed beam. Rock bolting rigs, charge rigs and survey vehicles may also include booms provided with feed beams. The improved feed beam disclosed in this patent application can be applied to all types of feed beams employed in mining operations.

[0057] The rock drilling rig 1 may comprise a movable transport carrier 2 and one or more booms 3 connected to the transport carrier 2 . At the distal portion of the boom 3 may be a drilling unit 4 . The drilling unit 4 may comprise a feed beam 5 and a rock drilling machine 6 supported on the feed beam 5 . The rock drilling machine 6 may comprise a drill shank at the front end of the rock drilling machine 6 for connecting the tool 7 . Furthermore, the drilling unit 4 may comprise one or more drill rod handling devices 8, such as tool holding devices, tool changing devices or robots, and tool magazines or tool stores. Besides, one or more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com