Geotechnical cloth thickness measuring device

A geotextile and thickness measurement technology, which is applied in the direction of mechanical thickness measurement, etc., can solve the problems of lower detection accuracy and damage to the detector, and achieve the effects of accurate measurement accuracy, slow movement of the meter head, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

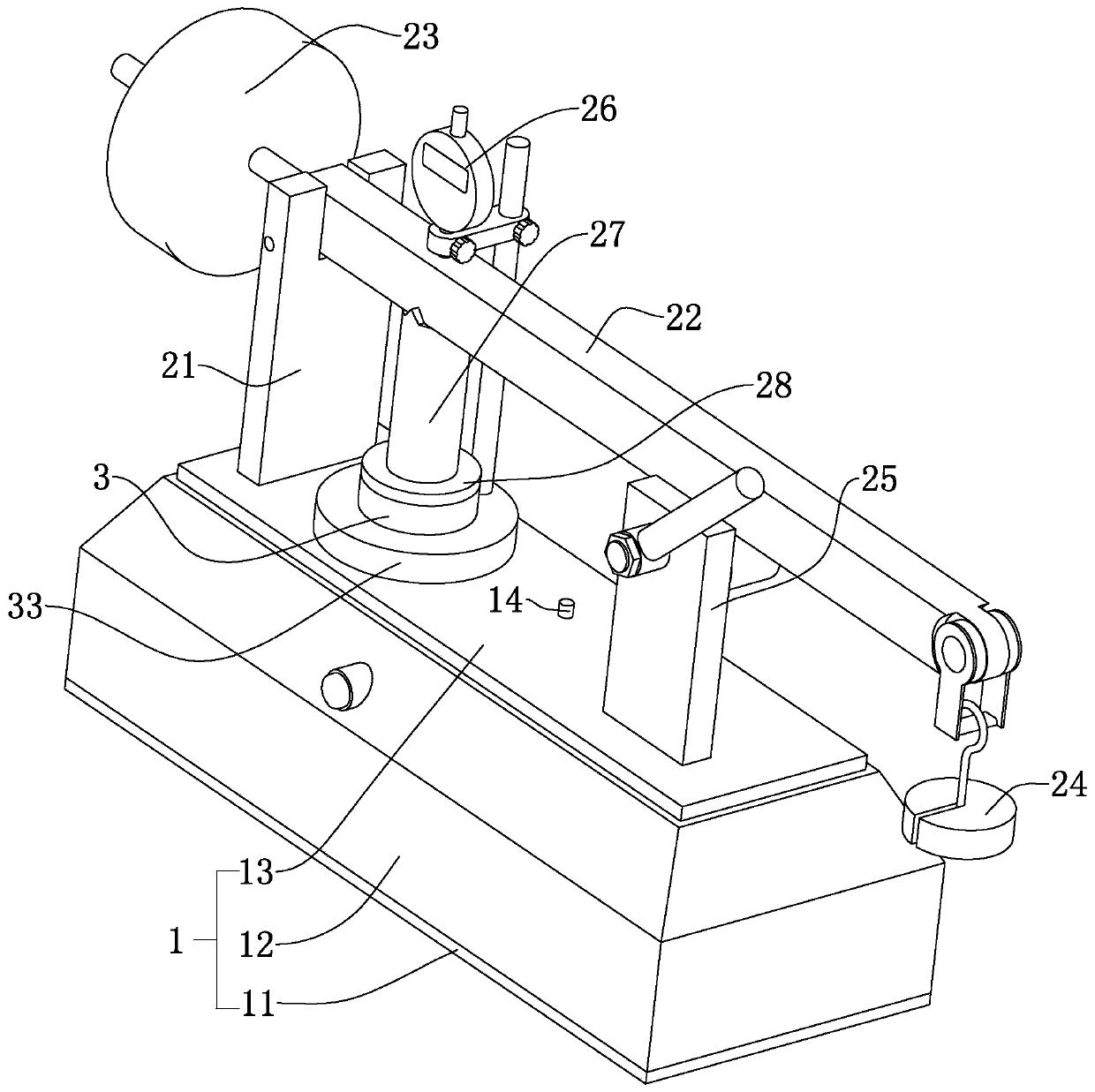

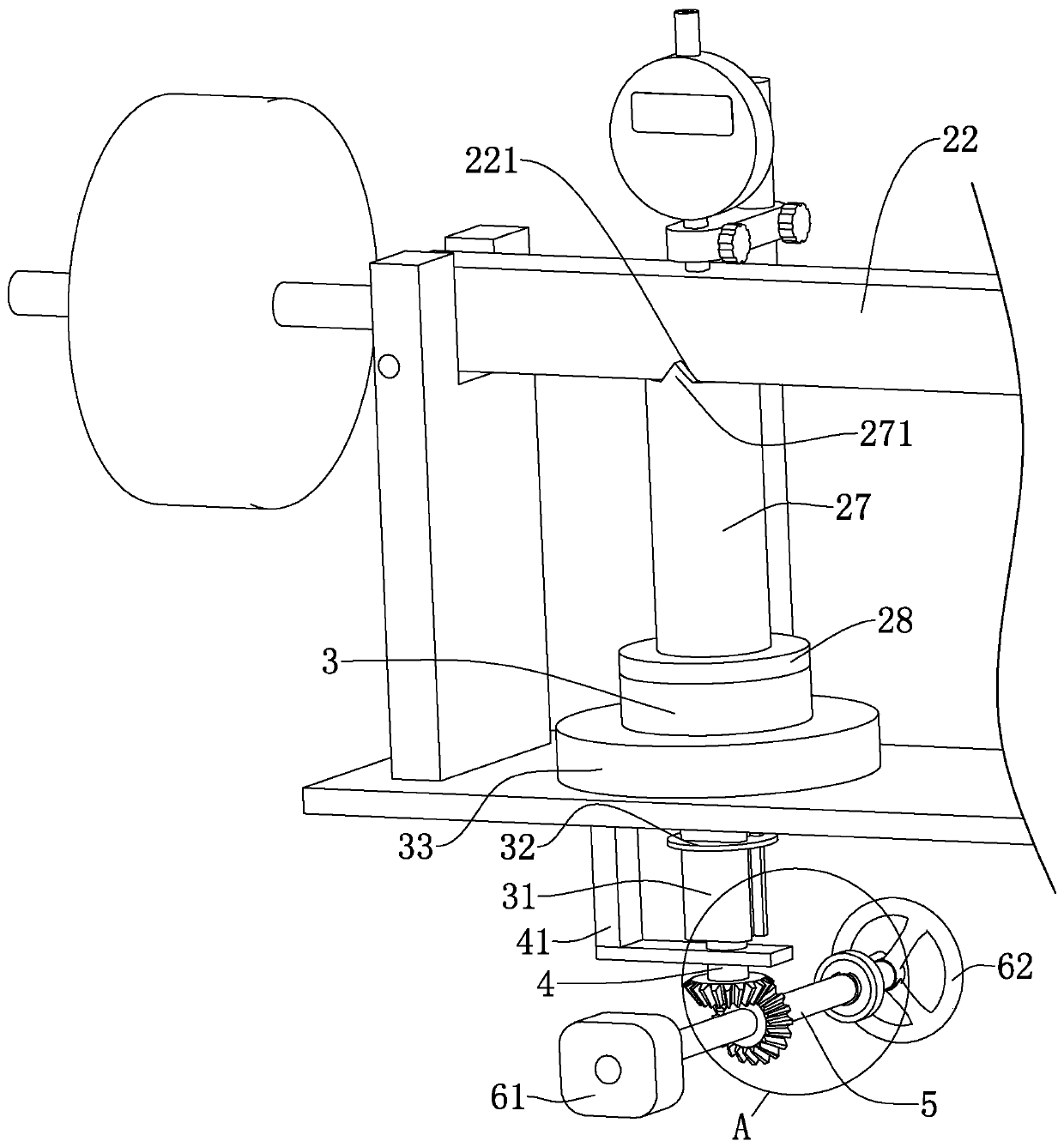

[0036] refer to figure 1 , discloses a geotextile thickness measuring device for the present invention, including a base 1, the base 1 includes a lower base plate 11, a side plate 12 and an upper base plate 13, the lower base plate 11 and the upper base plate 13 are steel plates with a square structure, and the side plates 12 are welded Between the upper bottom plate 13 and the lower bottom plate 11 , the base 1 is surrounded by a square-shaped housing.

[0037] refer tofigure 1 , The base 1 is provided with a measuring mechanism 2 . The measuring mechanism 2 comprises a vertical bar 27 welded on the surface of the upper base plate 13 facing away from the lower base plate 11. The vertical plate 21 is a square plate whose thickness direction is arranged along the length direction of the upper base plate 13. The vertical plate 21 is pierced with a hinge shaft, and the hinge shaft The axis is located in the horizontal plane, and the hinge shaft is covered with a pressure rod 22 ...

Embodiment 2

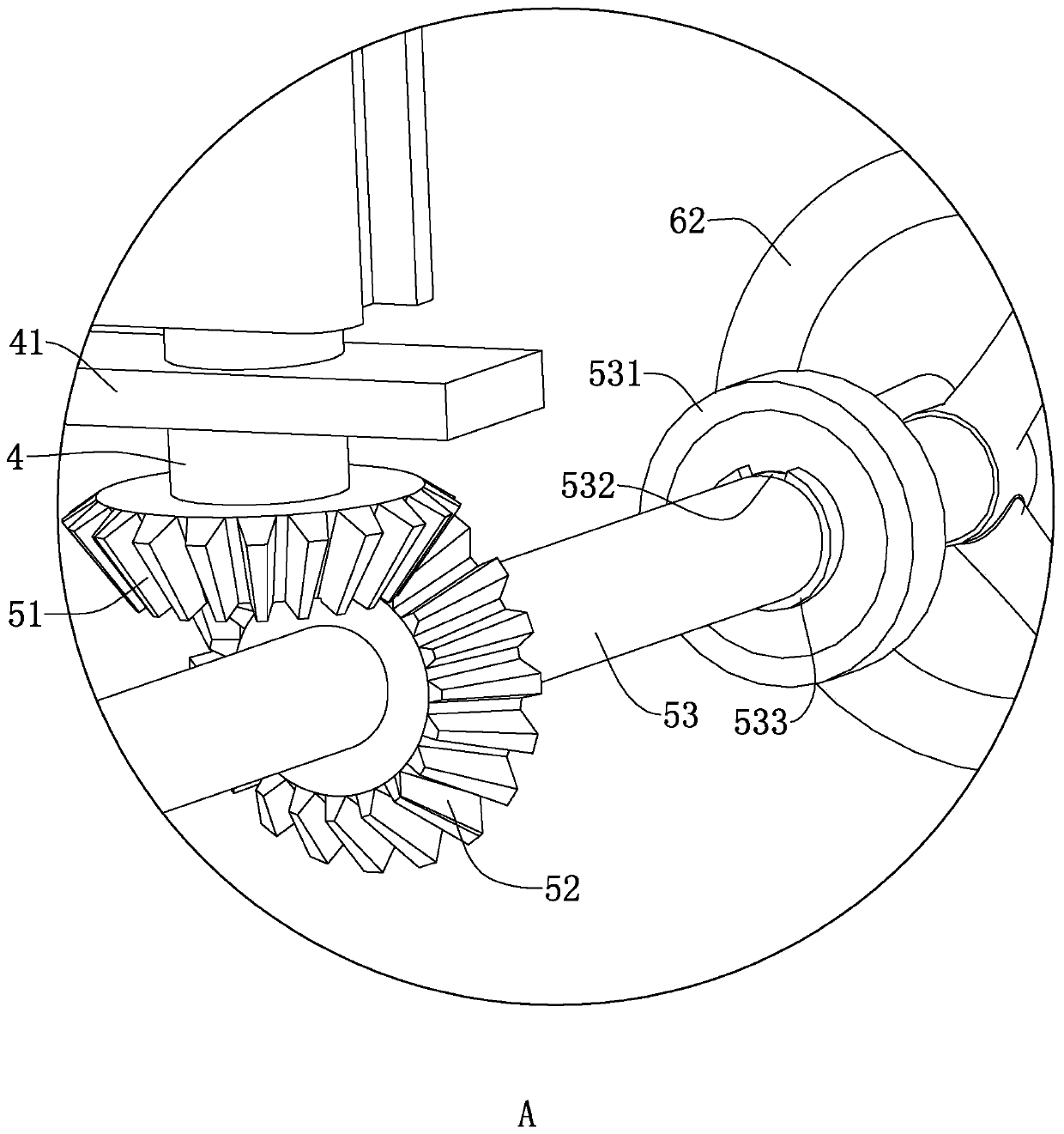

[0049] refer to Figure 5 , a geotextile thickness measuring device, the difference from Embodiment 1 is that the drive screw 4 is sleeved with a positioning ring 42 embedded in the lower bottom plate 11, the positioning ring 42 is rotationally connected with the drive screw 4, and the drive mechanism 5 It includes a worm wheel 54 that is sleeved on the outside of the drive screw 4 using a flat key. A worm 55 is meshed with the worm wheel 54. The worm 55 is rotationally connected with the base 1. One end of the worm 55 is connected to a drive motor 61 through a coupling, and the other end of the worm 55 is passed through The bolt compression connection is provided with a hand wheel 62 .

[0050] The implementation principle of the above-mentioned embodiment is:

[0051] The drive motor 61 drives the worm 55 to rotate, and the worm 55 drives the worm wheel 54 to rotate, so that the worm wheel 54 drives the drive screw 4 to rotate. The worm wheel 54 and the worm 55 have a good ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com