A battery pack for electric forklift

A technology for electric forklifts and battery packs, applied to secondary batteries, battery pack components, circuits, etc., can solve problems such as low heat dissipation efficiency, and achieve high heat dissipation efficiency, reasonable structure, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

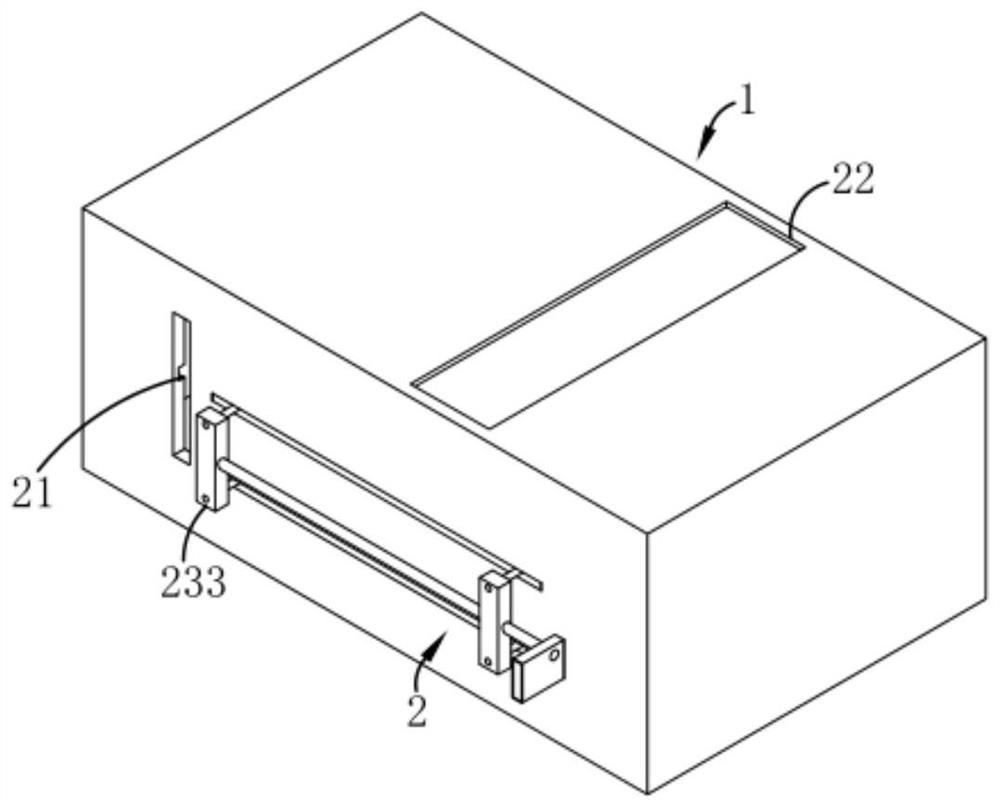

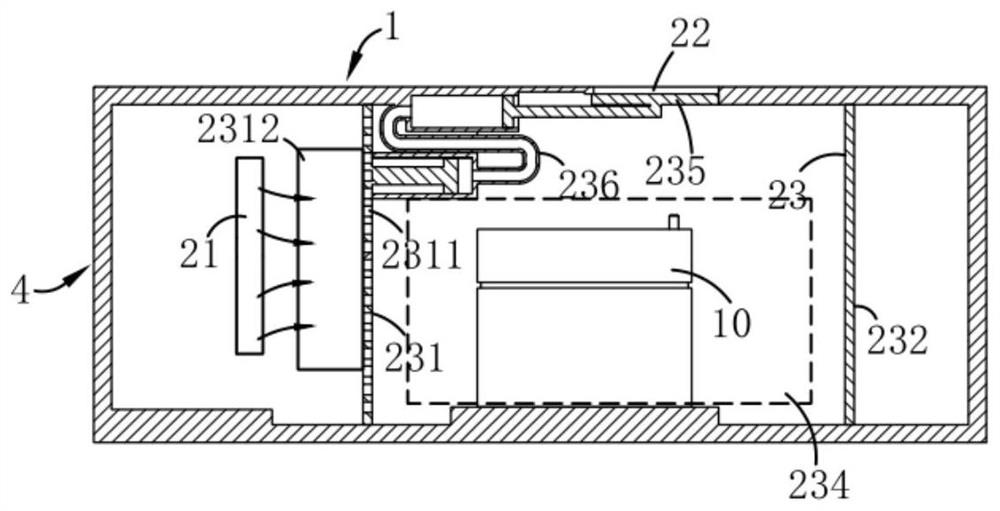

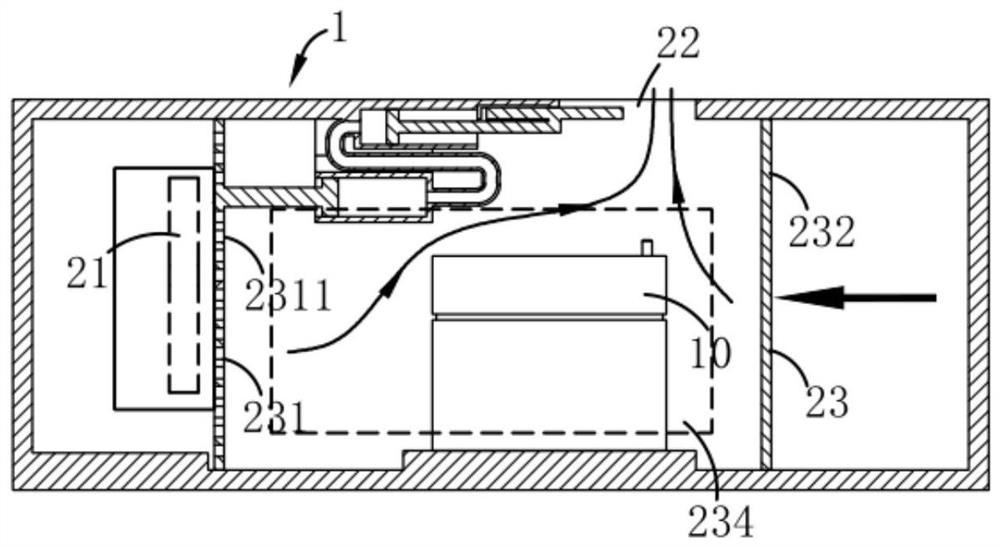

[0030] like Figures 1 to 4 As shown, a battery pack for an electric forklift, including a chassis 1, also includes:

[0031] The heat dissipation mechanism 2 is used to cool the battery 10 in the case 1. The heat dissipation mechanism 2 includes an air intake passage 21, an air outlet passage 22 and a compression assembly 23 opened in the case 1. The air intake Both the passage 21 and the air outlet passage 22 are opened on the chassis 1 and communicate with the outside; Dust removal process is carried out, the compression par...

Embodiment 2

[0034] like figure 1 , 5 , 6 and 7, wherein the same or corresponding parts as in the first embodiment adopt the corresponding reference numerals with the first embodiment, for the sake of simplicity, only the differences from the first embodiment are described below; the second embodiment is similar to the first embodiment The difference of Example 1 is that the compression assembly 23 also includes a transmission part 233 connecting the compression part 232 and the filter part 231, and the transmission part 233 includes a connection block A2331, a connection block B2332, a connecting rod 2333, and a return spring 2334 And the push plate 2335, the connection block A2331 and the connection block B2332 are fixedly connected with the filter part 231 and the compression part 232 respectively and are located outside the chassis 1, the connecting rod 2333 is fixed horizontally on the connection block B2332 and Slidingly connected with the connecting block A2331, the return spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com