A pcb automatic board throwing machine

A trigger, automatic technology, applied in the direction of conveyor objects, printed circuits, electrical components, etc., can solve the problems of inaccurate handling of installation and alignment, waste of time, and different shapes and specifications of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

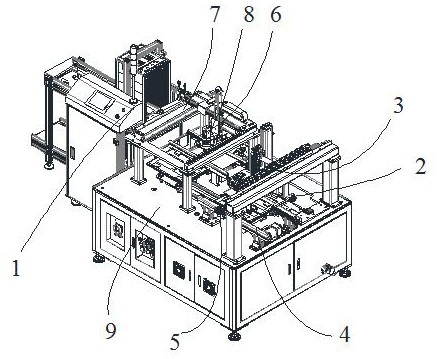

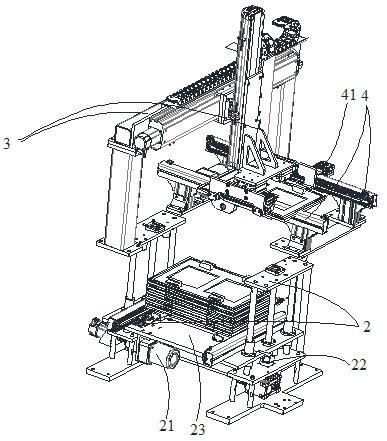

[0042] see figure 1 , a kind of PCB automatic board feeding machine of the present invention, through automatic PCB loading machine 1 dynamic loading, not only provide PCB bare board or have the materials such as PCBA board with some devices, at the same time contact with the moving PCB loading machine side by side The mold supply 2 of the placed machine 9 provides the carrier to the designated position, and at the same time the mold transfers 3 and moves the carrier to the mold positioning station 5 of the second transmission component 4 to realize the accurate reference point positioning of the carrier; three-axis The first conveying component 6 of the module assembly receives the material to the designated position provided with a blocking baffle. The blocking baffle is a positioning control device, such as a switch device set by an induction device, or an elastic baffle set and other objects ;When the material arrives at the designated position, the visual positioning 8 li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com