A Repair Process for the Sealing Surface of Nuclear-Grade Gate Valve Plate

A sealing surface and nuclear-grade gate technology, which is applied in the field of nuclear-grade gate valve valve plate sealing surface repair technology, can solve the primary pressure boundary damage of the primary circuit and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

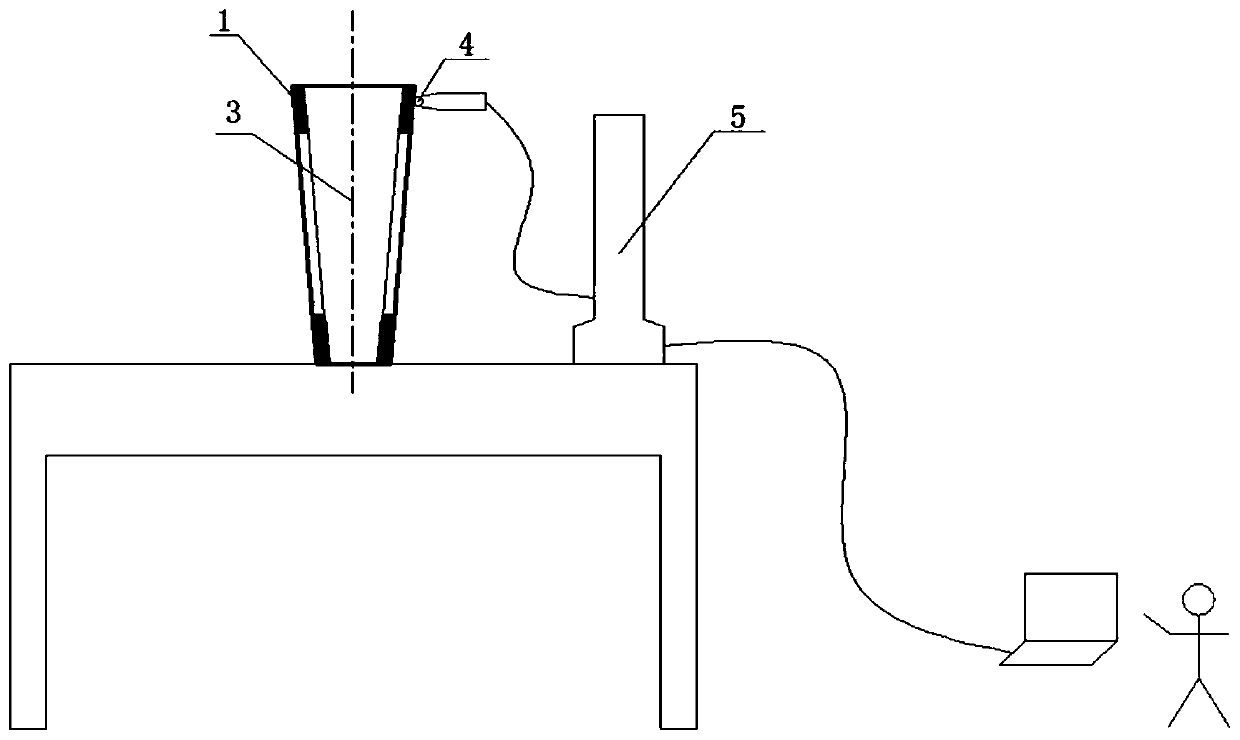

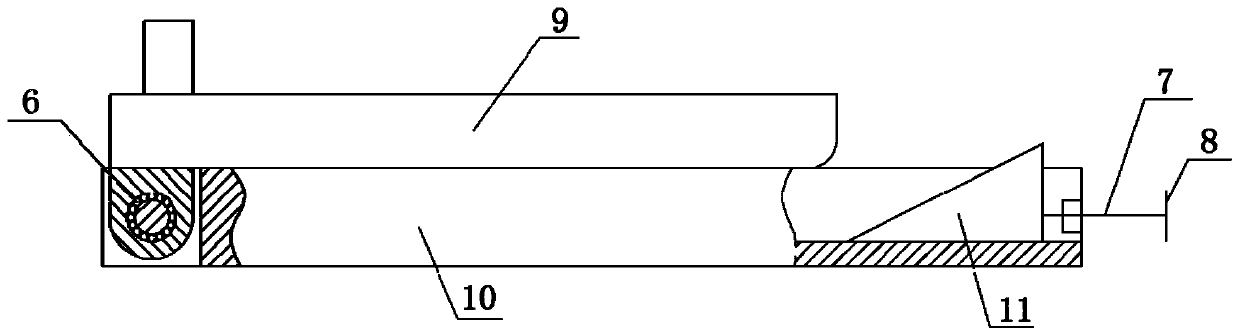

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0042] A process for repairing the sealing surface of a nuclear-grade gate valve plate, which specifically includes the following steps:

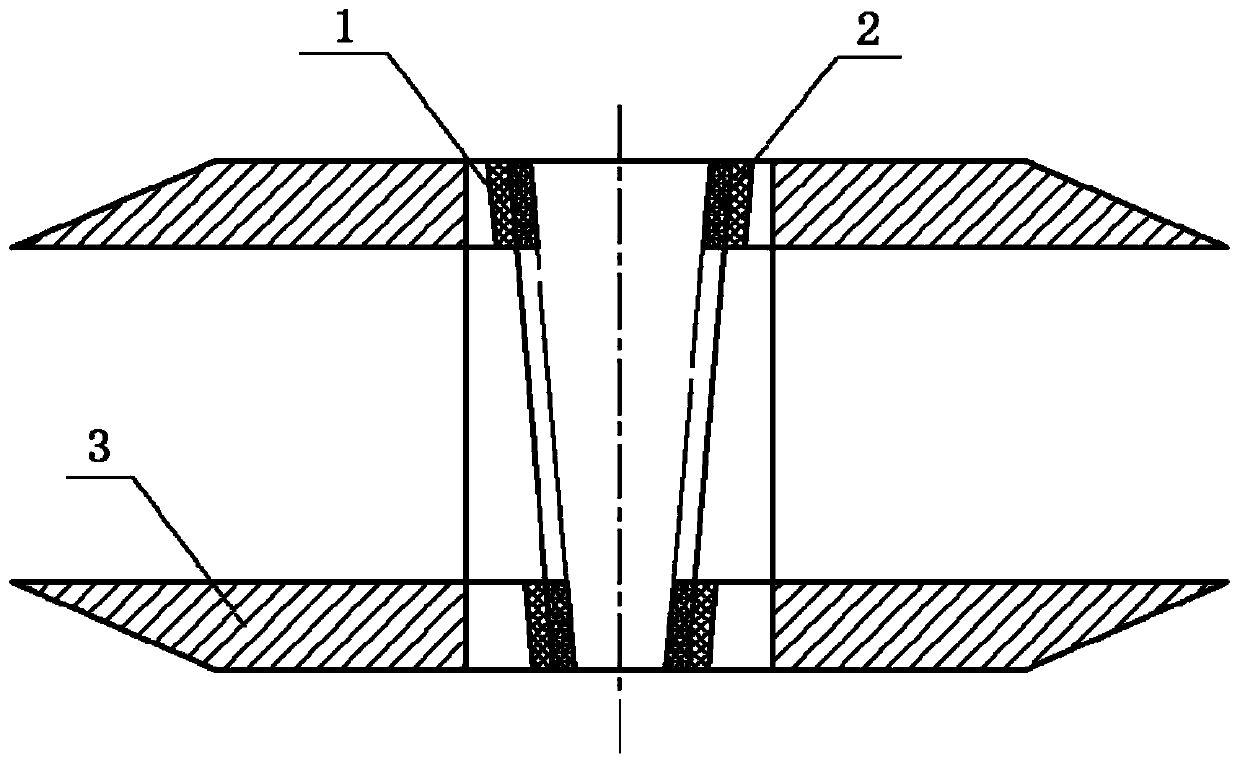

[0043] 1.1. There is a defect in the sealing surface of the valve plate 2 of the valve body 3 of the highly radioactive nuclear-grade gate valve.

[0044] 1.2. Collect information such as the structure of the valve to be repaired, the valve plate body and the material of the sealing surface.

[0045] 1.3. Combining with the material of the valve plate body and sealing surface, write the welding process qualification and heat treatment process and pass the review.

[0046] 1.4. Prepare corresponding welding consumables and simulation bodies in combination with welding procedure qualification.

[0047]1.5. Carry out simulation verification on the simulation body according to the welding procedure qualification and he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com