Steam ejector

An ejector, steam technology, used in washing devices, hand irons, textiles and papermaking, etc., can solve problems such as clothing getting wet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

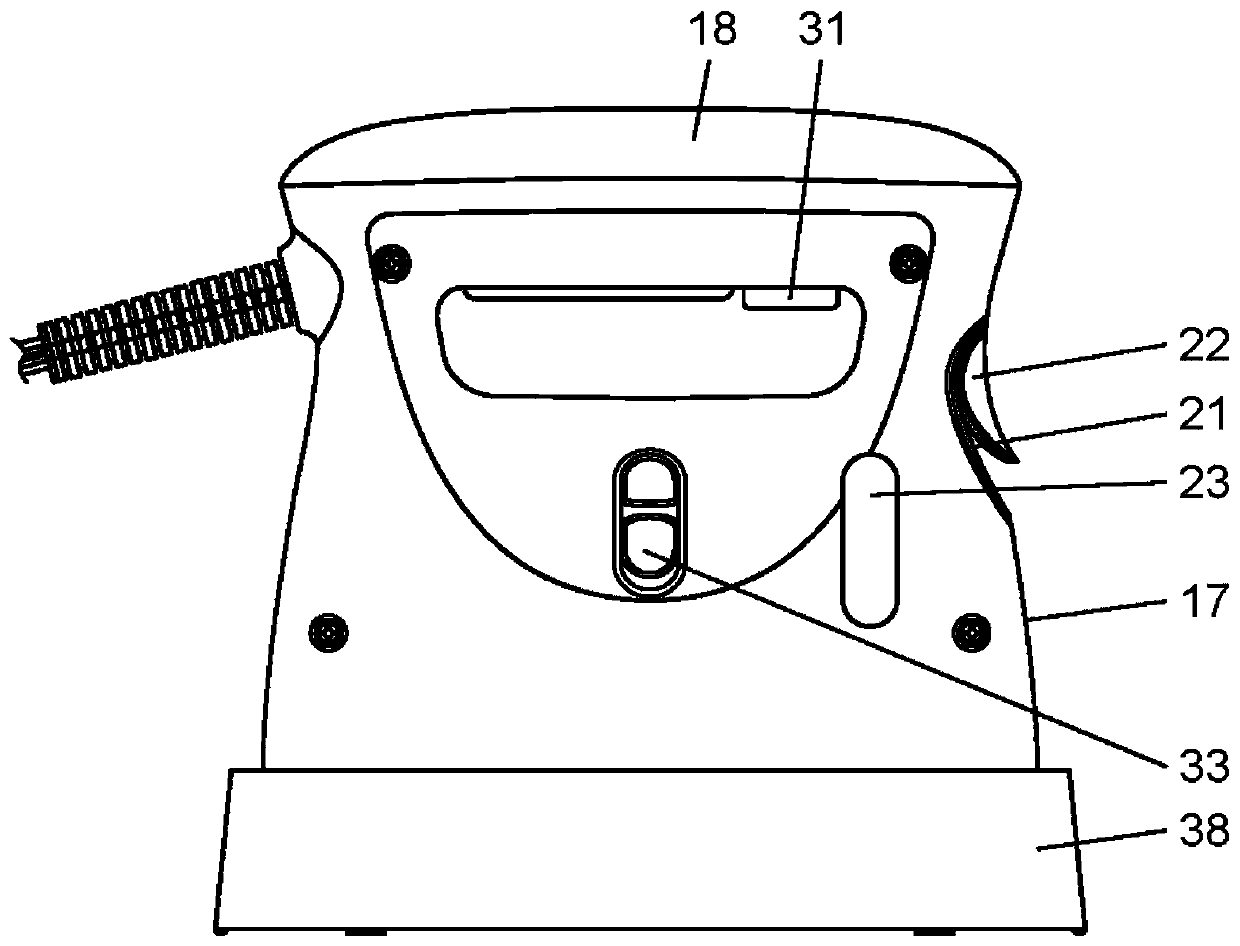

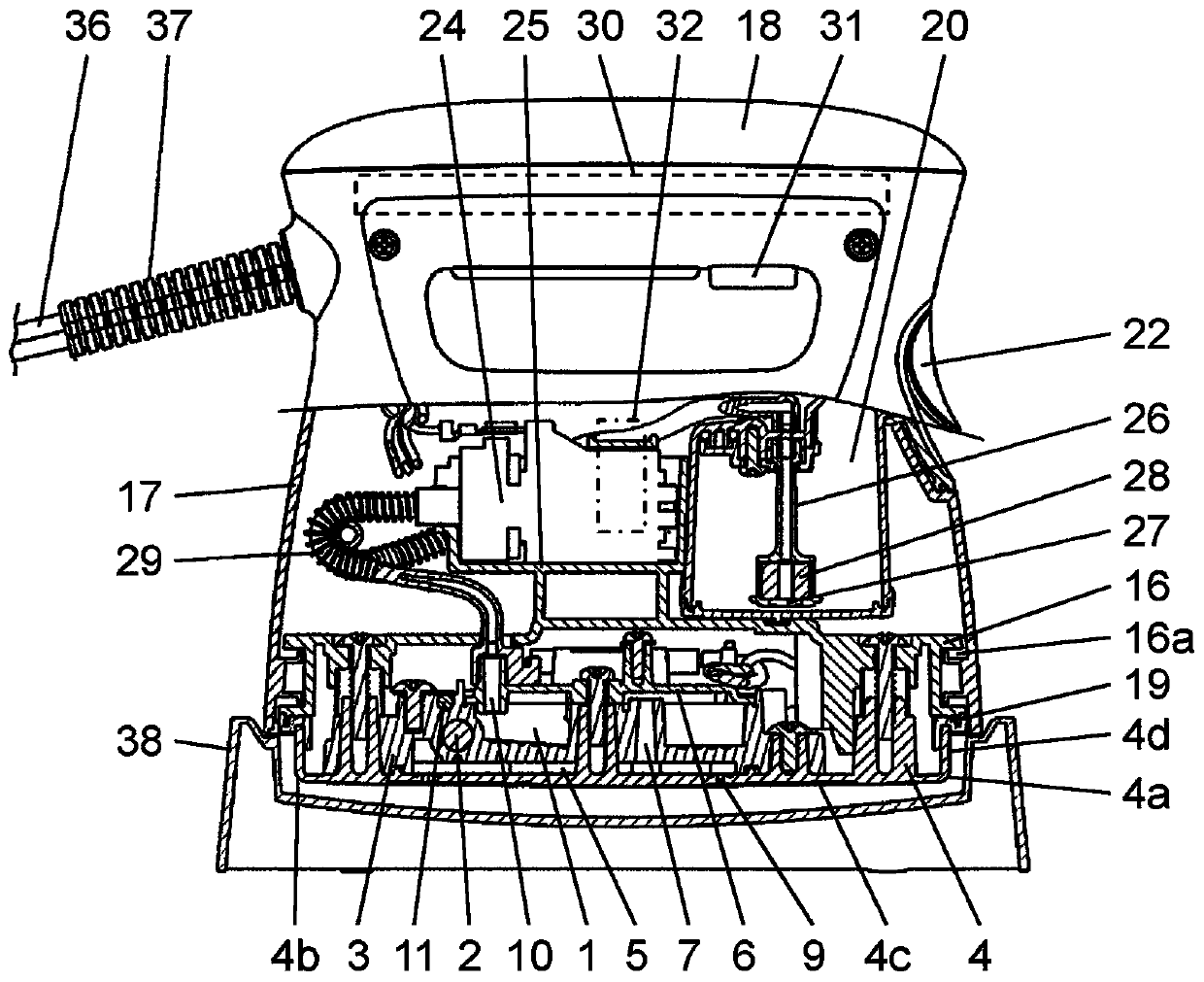

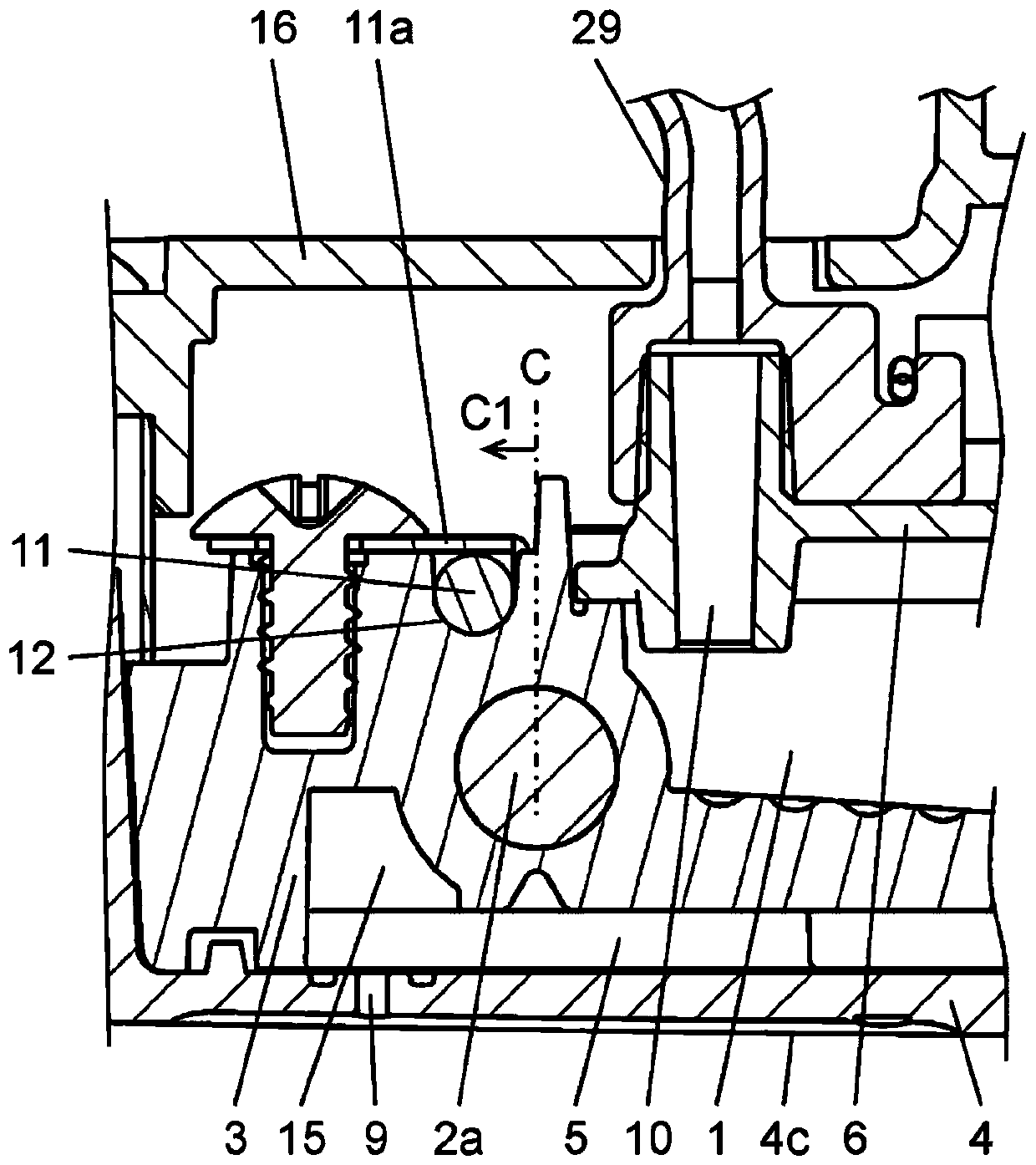

[0024] The steam ejector according to the first aspect of the present disclosure includes a vaporization chamber, a heater, a water tank, an electric pump, an operation unit, and a control unit.

[0025] The vaporization chamber is used to generate steam. The heater heats the vaporization chamber. The tank is used to store water. An electric pump is used to supply water from the tank to the vaporization chamber. The operation unit outputs the first signal and the second signal, respectively, according to two different operations performed by the user. The control unit drives the electric pump according to the first signal to generate constant steam, and drives the electric pump according to the second signal to temporarily generate incremental steam larger than the steam amount of the constant steam.

[0026] In the steam ejector according to the second aspect of the present disclosure, in addition to the first aspect, the operation unit outputs the first signal according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com