Sealing water stopping strip capsule of fabricated underground structure prefabricated part joint

A technology of prefabricated components and underground structures, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problem that waterproof gaskets are difficult to squeeze and deform, and achieve the effect of ensuring the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

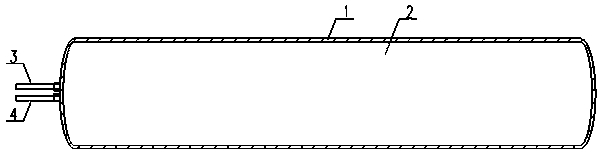

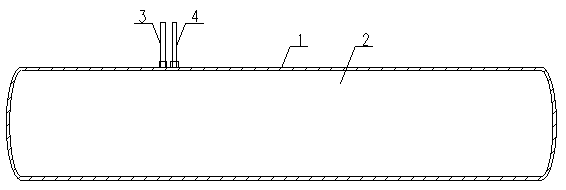

[0049] Such as Figure 7 As shown, a water-stop bag can be installed at the corresponding position of the joints of the prefabricated parts formed by No. Correspondingly, after inflating or pouring cement slurry, the side walls of the two water-stop strips are squeezed to achieve the purpose of sealing and water-stopping.

Embodiment 2

[0051] Such as Figure 8 As shown, a water-stop strip can be installed on the prefabricated component at the joint side of the prefabricated component formed by No. After expansion, the side wall of the prefabricated component on the other side is squeezed to achieve the purpose of sealing and watertight.

Embodiment 3

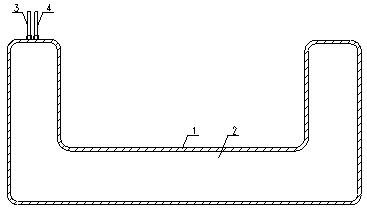

[0053] Such as Figure 9 As shown, the water-stop strip can be applied to the water-stop of the joints between the prefabricated ground and wall webs. Paste the sealed water-stop strip bag in the reserved groove of the Nth sheet 7 of the prefabricated ground connection wall, insert the N-th sheet 7 of the prefabricated floor connection wall into the groove by using the mud retaining method, and extract the air in the water-stop bag to prevent it Block the insertion of the N+1th ground connection wall.

[0054] Insert the concave-convex tenons at the joints between the N+1 and 8th prefabricated floor connecting walls into the grooves, and after the positioning of the two adjacent floor connecting walls is completed, inject micro-expansion cement slurry into the capsule body 1 through the grouting nozzle 4 , Stop grouting after reaching the set pressure of 0.3MPa, after the grout solidifies, the purpose of sealing and water-stopping the inter-web joints can be achieved.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com